Stirring drying machine for marble chocolates

A chocolate bean and dryer technology, applied in the direction of dryer, drying, non-progressive dryer, etc., can solve the problems of uneven hot air, uneven drying of chocolate beans, etc., to improve the quality and drying effect Good, even drying results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing.

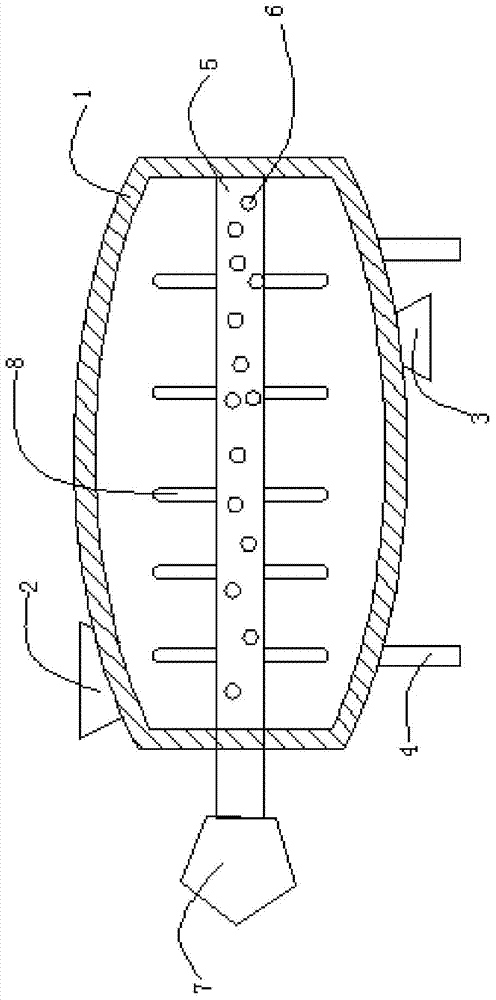

[0011] The invention provides a stirring and drying machine for chocolate beans, which comprises a horizontally arranged mixing drum, feet are provided on the wall of the mixing drum, a material inlet and a material outlet are arranged on the mixing drum, and inside the mixing drum A hollow rotating shaft is provided, and the rotating shaft is driven to rotate by a driving motor. There are several hot air outlets on the rotating shaft, a hot air blower is connected to one end of the rotating shaft, and spiral rotating blades are arranged on the rotating shaft. . Pour the chocolate beans into the mixing drum and stir. At the same time, because the mixing drum is equipped with a rotating shaft, and through the hollow rotating shaft, the hot air is conveyed into the rotating shaft. Through the hot air holes on the rotating shaft, the hot air can be evenly conveyed into the In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com