Multifunctional mincing machine

A kind of meat grinder, multi-functional technology, applied in sausage stuffing machine, grain processing, etc., can solve the problems that are unfavorable for families or shops to save money, and it is not easy to use sausage stuffing machine and meat grinder in combination, so as to achieve good meat feeling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

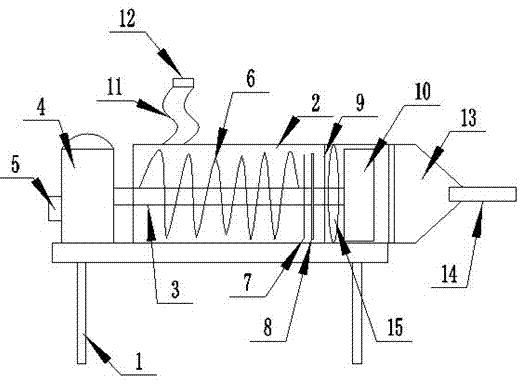

[0014] Such as figure 1 A kind of multifunctional meat grinder shown, comprises frame 1, casing 2 and rotating shaft 3; Described casing 2 is installed on the frame 1; The left end of described casing 2 is equipped with motor 4; The rotating shaft 3 is installed in the casing 2; the motor 4 is provided with a gear adjustment button 5; the rotating shaft 3 is sequentially installed with a propulsion screw 6, a cross knife 7, a twisting knife 8, and a discharge orifice 9 from left to right and agitator 10; the casing is provided with a feed inlet 11; the feed inlet 11 is equipped with a feed cover 12, which can prevent the entry of sundries and dust; the right end of the casing 2 is movably connected with A discharge cylinder 13; a nozzle 14 is connected to the outlet of the discharge cylinder 13.

[0015] Wherein, the material inlet 11 is in an "S" shape; a capstan 15 is arranged between the discharge orifice 9 and the agitator 10; the motor 4 is a single-phase asynchronous mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com