Molded body, method of manufacturing the same, seat material for vehicles, and method of manufacturing the same

A manufacturing method and molding technology, which are applied to vehicle seats, vehicle components, special positions of vehicles, etc., can solve the problems of insufficient bonding of boundary parts, weak bonding strength, and inability to foam, and achieve a good ride. Comfort, Vibration Suppression Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] Next, an embodiment of the present invention will be described.

[0087] (Structure of Seat Parts for Vehicles)

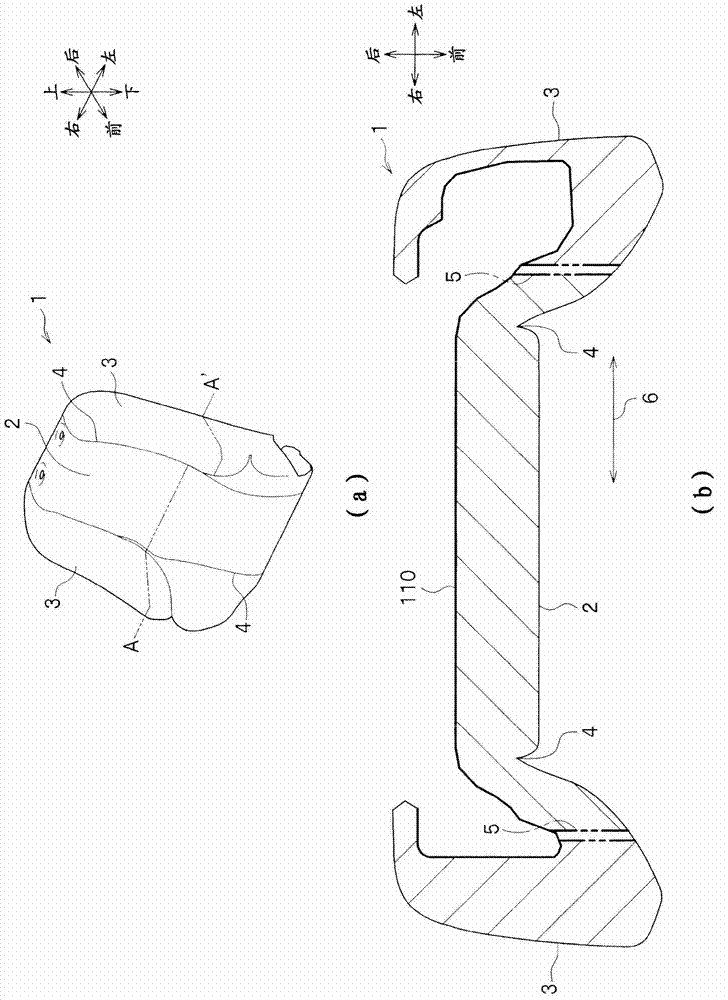

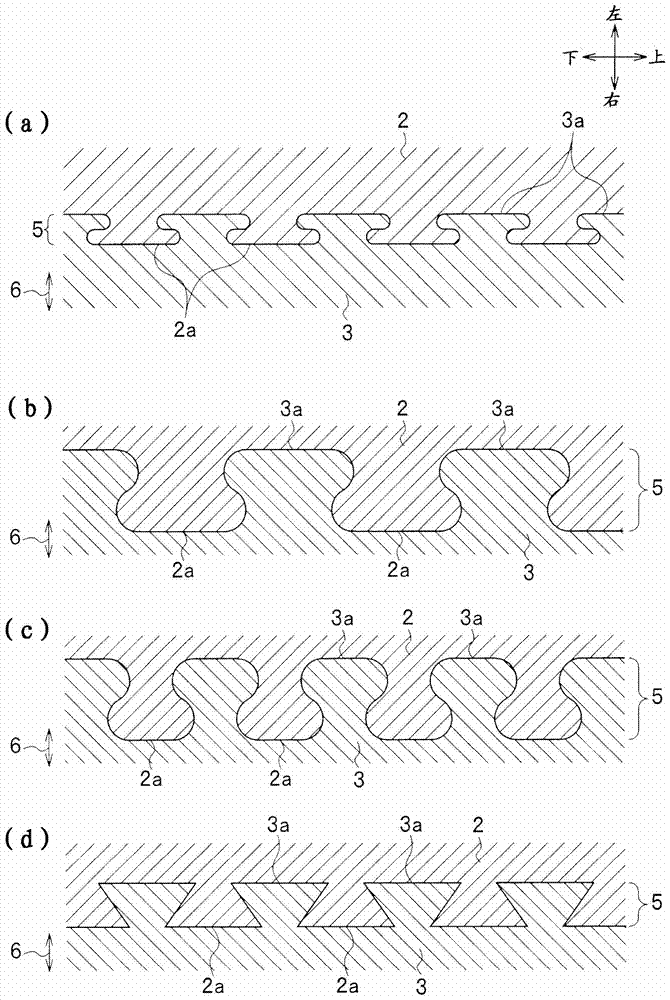

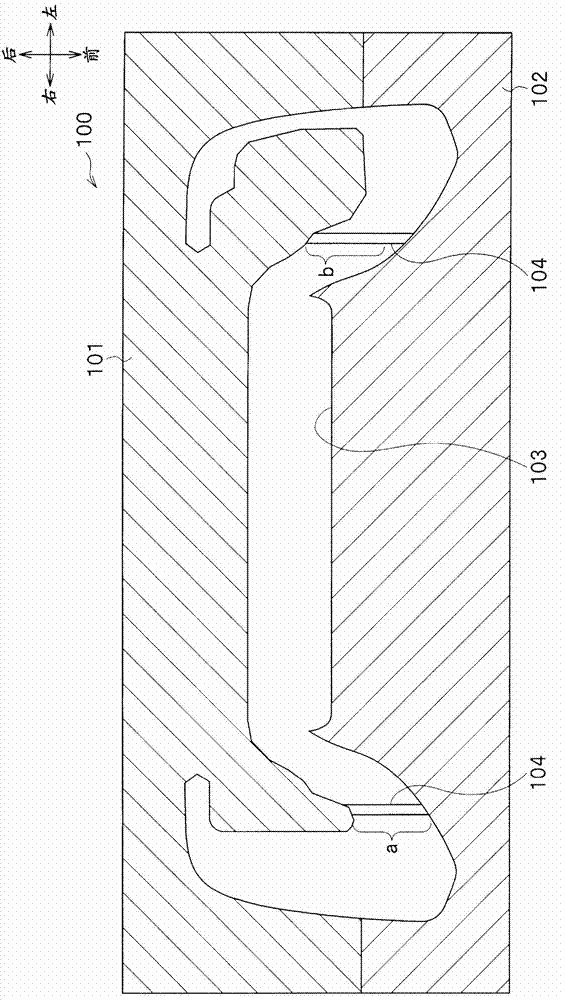

[0088] First, the structure of the vehicle seat component of the present embodiment will be described. figure 1 Among them, (a) is a perspective view of the vehicle seat member 1, and (b) is an enlarged cross-sectional view cut along line A-A' of (a). in addition, figure 1 The directions for the vehicle in which the vehicle seat member 1 is mounted are shown in the drawings and subsequent drawings. This vehicle seat component 1 (molded body) is a seat back pad forming a vehicle seat. That is, the seat back of the vehicle seat is formed by covering the vehicle seat member 1 with a surface material such as leather or cloth. This vehicle seat member 1 is composed of a main body portion 2 (first molded product) and a guard portion 3 (second molded product), wherein the main body portion 2 constitutes a central portion of the vehicle seat member 1 in the vehi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com