Automatic processing process of stainless steel seamless steel pipe

A seamless steel pipe and automatic processing technology, applied in the field of metal processing, can solve the problem of large gap between double-layer composite pipes and pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

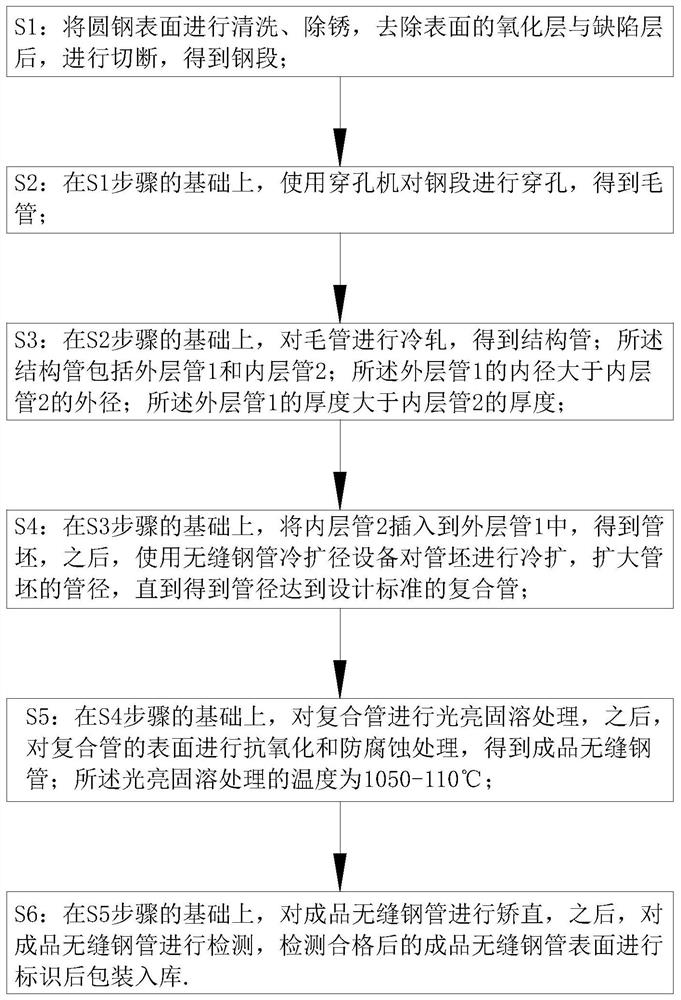

[0054] Embodiment one: a kind of automatic processing technique of stainless steel seamless steel pipe, comprises the following steps:

[0055] S1: Clean and derust the surface of the round steel, remove the oxide layer and defect layer on the surface, and then cut it to obtain the steel section;

[0056] S2: On the basis of step S1, use a piercer to perforate the steel section to obtain a capillary tube;

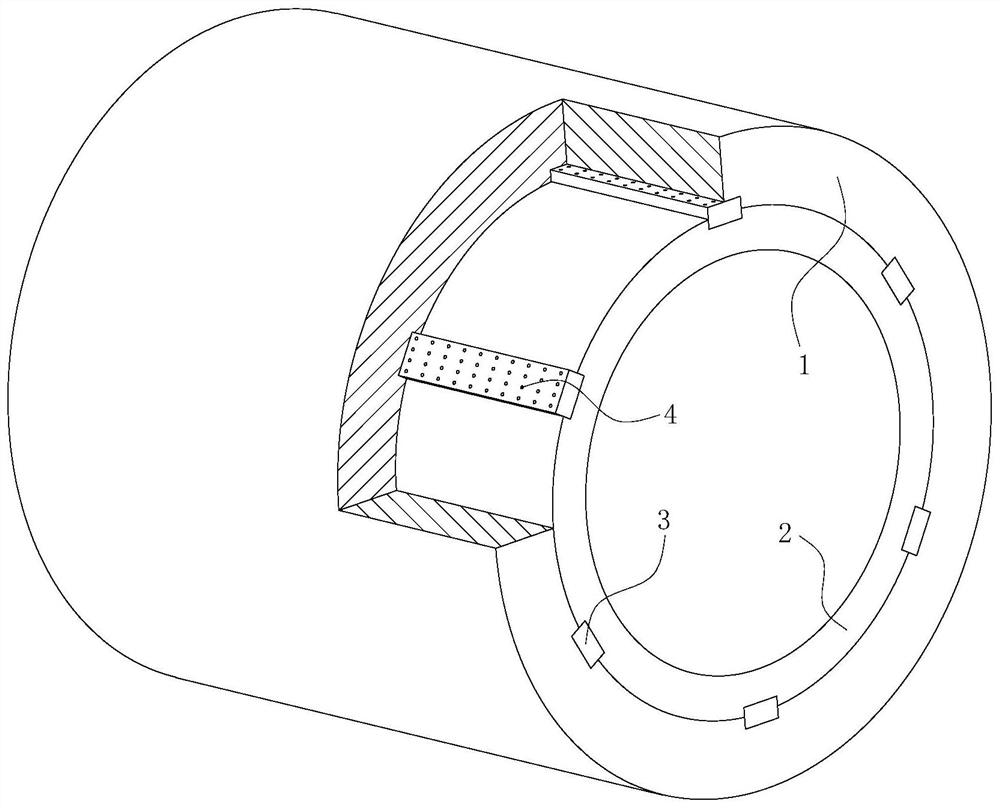

[0057] S3: On the basis of step S2, cold-roll the capillary tube to obtain a structural tube; the structural tube includes an outer tube and an inner tube; the inner diameter of the outer tube is larger than the outer diameter of the inner tube; the outer tube The thickness of the layer pipe is greater than the thickness of the inner layer pipe;

[0058] S4: On the basis of step S3, the inner tube is inserted into the outer tube to obtain a tube blank, and then the tube blank is cold-expanded using a seamless steel tube cold expansion device to expand the tube diameter unt...

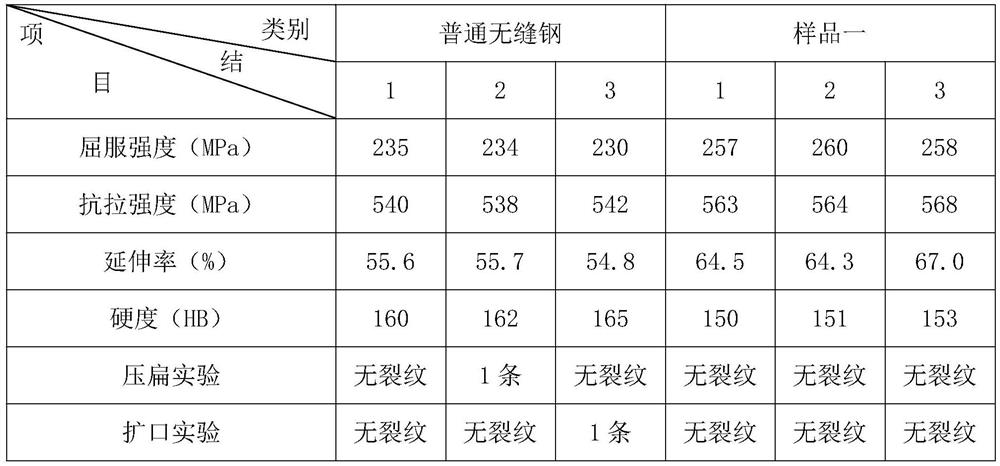

Embodiment 2

[0066] Embodiment 2: This embodiment provides an automatic processing technology for stainless steel seamless steel pipes. The processing technology is consistent with the processing technology in Embodiment 1, but in the processing process, the inner tube and the outer tube are not Insert reinforcing ribs.

Embodiment 3

[0067] Embodiment 3: This embodiment provides an automatic processing technology for stainless steel seamless steel pipes. The processing technology is consistent with the processing technology in Embodiment 1. The outer wall of the layer pipe and the inner wall of the outer layer pipe have not been sandblasted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com