Sheet conveying device and image forming apparatus

A technology for conveying devices and sheets, applied in printing devices, transportation and packaging, thin material handling, etc., can solve the problems of reduced charging efficiency, affecting conveyor belt drive, and reduced sheet adsorption force, so as to suppress the impact and prevent floating. effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

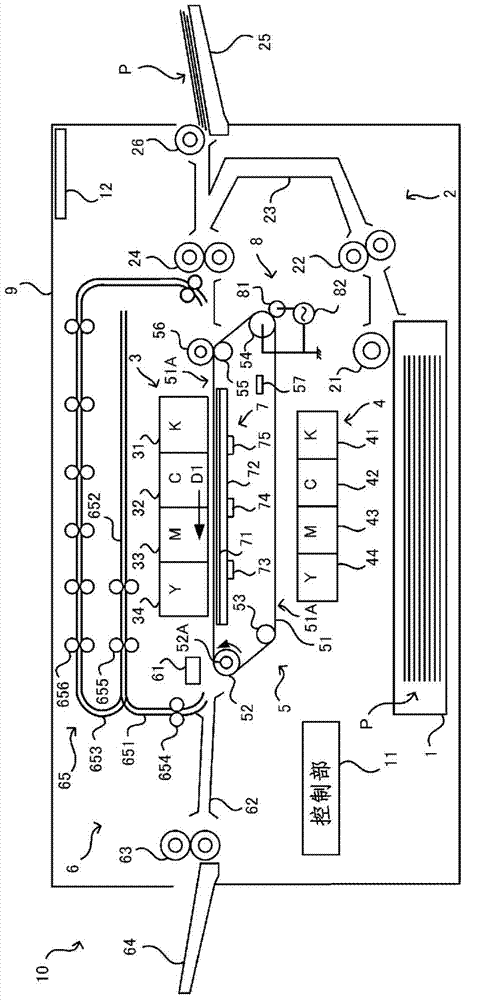

[0024] First, refer to figure 1 A schematic configuration of the image forming apparatus 10 according to the first embodiment of the present invention will be described.

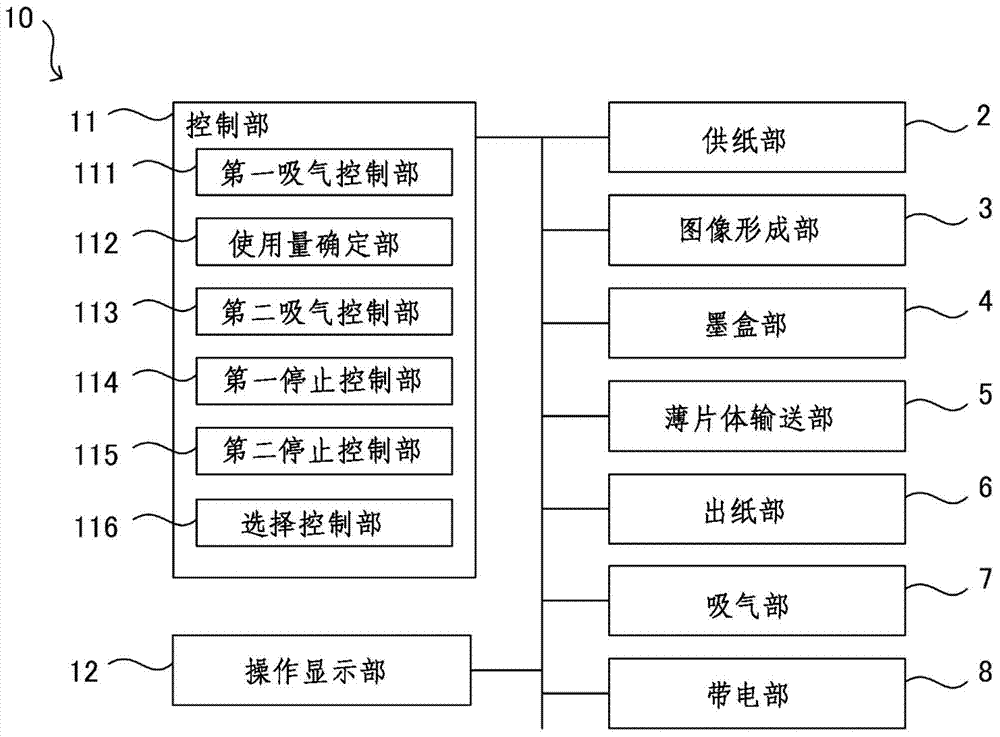

[0025] The image forming apparatus 10 includes: a paper feeding cassette 1 , a paper feeding unit 2 , an image forming unit 3 , an ink cartridge unit 4 , a sheet conveying unit 5 , a paper discharge unit 6 , an air suction unit 7 , a charging unit 8 , and a control unit 11 . , The operation display unit 12 and the main body frame 9 . The image forming apparatus 10 is an inkjet printer that forms an image on a sheet using aqueous ink based on print data (image data) input from an information processing apparatus such as a personal computer. In addition, the image forming apparatus of the present invention is not limited to a printer, but can also be applied to a copier, a facsimile apparatus, a digital multi-function peripheral, or the like. In addition, an apparatus including at least the sheet conveying u...

no. 2 approach

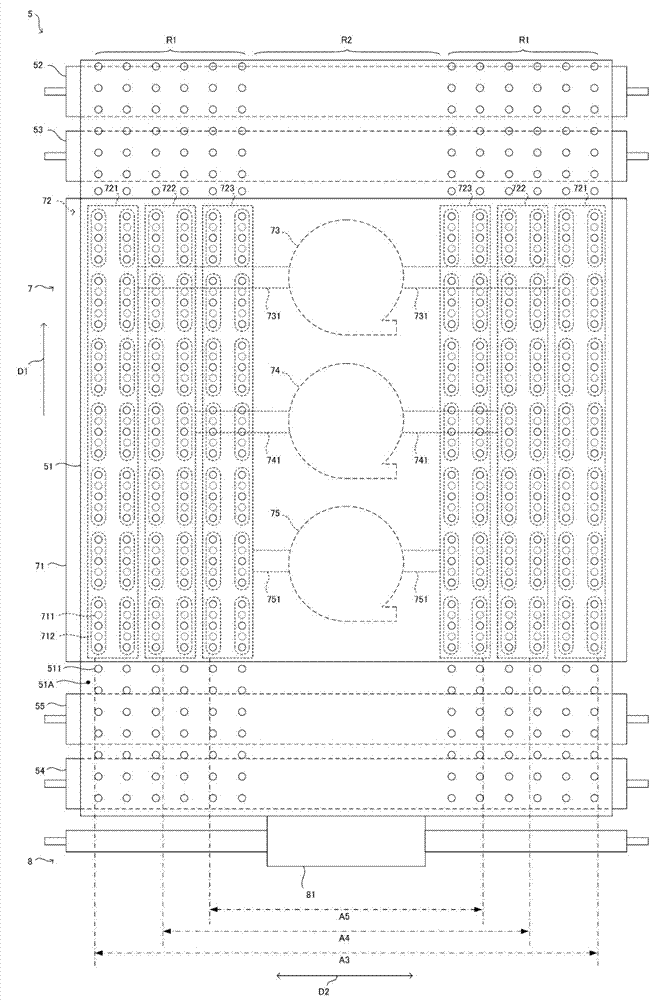

[0126] Next, a second embodiment of the present invention will be described. In addition, in this second embodiment, the description of the same configuration and processing as those of the first embodiment will be omitted, and the points of difference from the first embodiment will be described. here, Figure 6 A schematic view of the conveyor belt 51 viewed from above, Figure 7 It is a diagram showing the circuit configuration of the charging unit 8 .

[0127] Such as Figure 6As shown, in the width direction D2 perpendicular to the conveying direction D1 of the sheet P and in the predetermined plurality of suction and adsorption areas R1 corresponding to the ends of various sizes of the sheet P Inside, the tape openings 511 are formed at predetermined intervals in the conveyance direction D1. More specifically, each of the belt openings 511 is formed such that an end surface of the sheet P in the width direction D2 corresponding to the size of the sheet P corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com