Calcium citrate producing method

A technology of calcium citrate salt and production method, applied in the directions of carboxylate preparation, carboxylate preparation, chemical instruments and methods, etc., can solve the problems of energy consumption and consumption of many raw and auxiliary materials, complicated procedures, and generation of solid waste gypsum, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

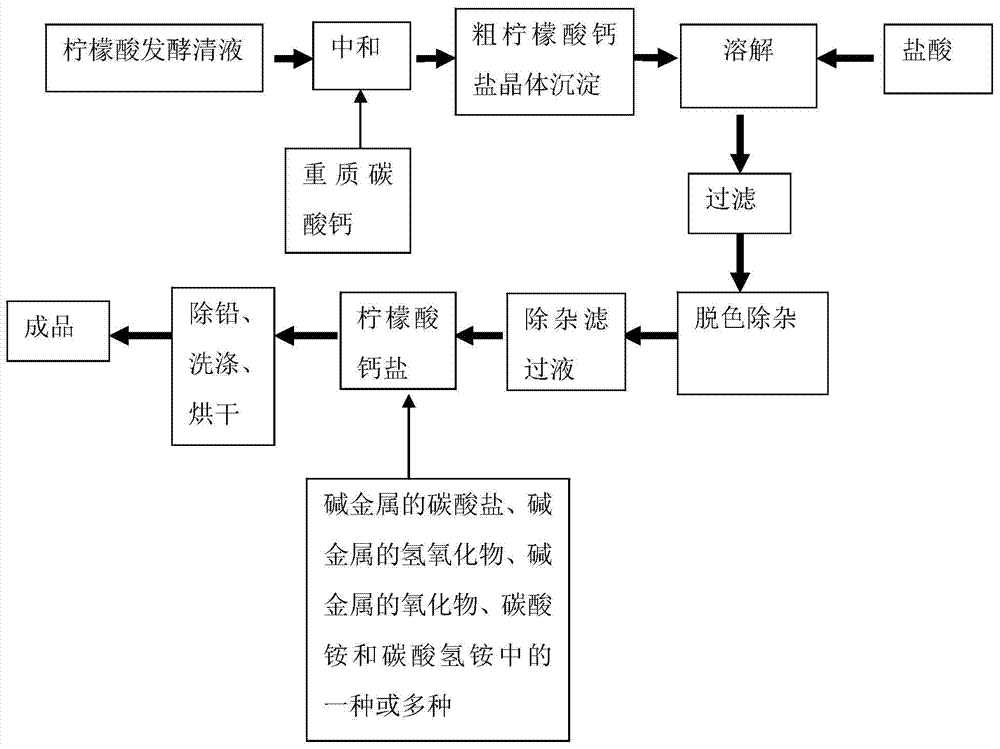

Method used

Image

Examples

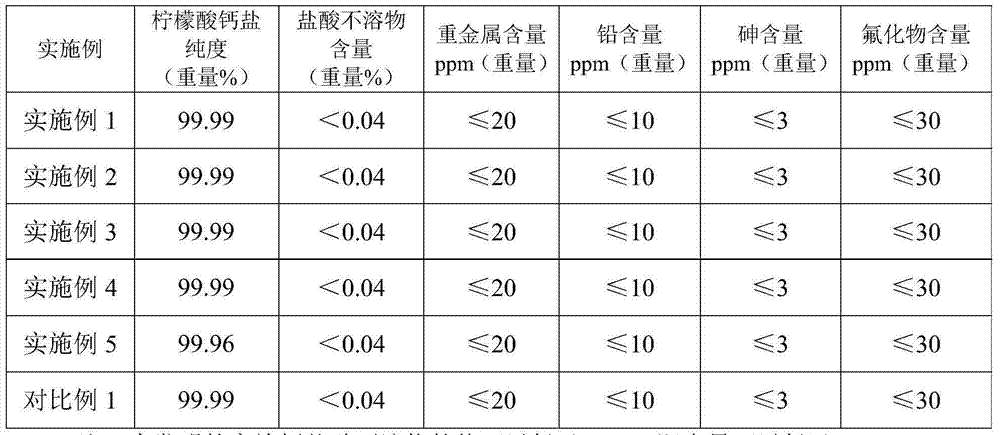

Embodiment 1

[0044] This embodiment is used to illustrate the production method of calcium citrate of the present invention.

[0045] 1000ml of citric acid fermentation clear liquid (acidity is 130g / L, turbidity is 20NTU) and 100 grams of heavy calcium carbonate particles (calcium carbonate purity 95% by weight, hydrochloric acid insoluble matter content 3% by weight, heavy metal content 0.5% by weight, Lead content 0.3% by weight, arsenic content 0.2% by weight, fluoride content 0.1% by weight, diameter: 10-400 microns) at 80°C for neutralization reaction, and the pH at the end of the reaction is controlled to be 4.7. Gained neutralization product is carried out suction filtration and obtains free water content and is the thick calcium citrate crystal of 50% by weight, with the hot water washing thick calcium citrate crystal of 2 times of wet calcium citrate volume with total amount, make citric acid Calcium-washed sugar water is oxidized with potassium permanganate for 3 minutes to obtai...

Embodiment 2

[0047] This embodiment is used to illustrate the production method of calcium citrate of the present invention.

[0048] 1000ml of citric acid fermentation liquid (acidity is 130g / L, turbidity is 20NTU) and 100 grams of heavy calcium carbonate particles (calcium carbonate purity 95.5% by weight, hydrochloric acid insoluble content 3% by weight, heavy metal content 0.5% by weight, Lead content 0.3% by weight, arsenic content 0.1% by weight, fluoride content 0.1% by weight, diameter: 10-400 microns) at 75°C for neutralization reaction, and the pH at the end of the reaction is controlled to be 4.6. Gained neutralization product is carried out suction filtration and obtains free water content and is the thick calcium citrate crystal of 50% by weight, with the hot water washing thick calcium citrate crystal of 0.5 times of wet calcium citrate volume with total amount, make citric acid Calcium-washed sugar water is oxidized with potassium permanganate for 3 minutes to obtain rough c...

Embodiment 3

[0050] This embodiment is used to illustrate the production method of calcium citrate of the present invention.

[0051] 1000ml of citric acid fermentation liquid (acidity is 130g / L, turbidity is 20NTU) and 100 grams of heavy calcium carbonate particles (calcium carbonate purity 96% by weight, hydrochloric acid insoluble content 3% by weight, heavy metal content 0.5% by weight, Lead content 0.3% by weight, arsenic content 0.1% by weight, fluoride content 0.2% by weight, diameter: 10-400 microns) at 85°C for neutralization reaction, and the pH at the end of the reaction is controlled to be 4.8. Gained neutralization product is carried out suction filtration and obtains free water content and is the thick calcium citrate crystal of 50% by weight, with the hot water washing thick calcium citrate crystal of 3 times of wet calcium citrate volume with total amount, make citric acid Calcium-washed sugar water is oxidized with potassium permanganate for 3 minutes to obtain rough calci...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap