Lateral type backlight module

A side-entry backlight and module technology, which is applied in the field of side-entry backlight modules, can solve the problems of strong light in the middle of the light-emitting diode, inconsistent excitation of phosphor powder, uneven brightness and darkness of the backlight module, etc., to achieve reduced light intensity and simple structure , Eliminate the effect of dark areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

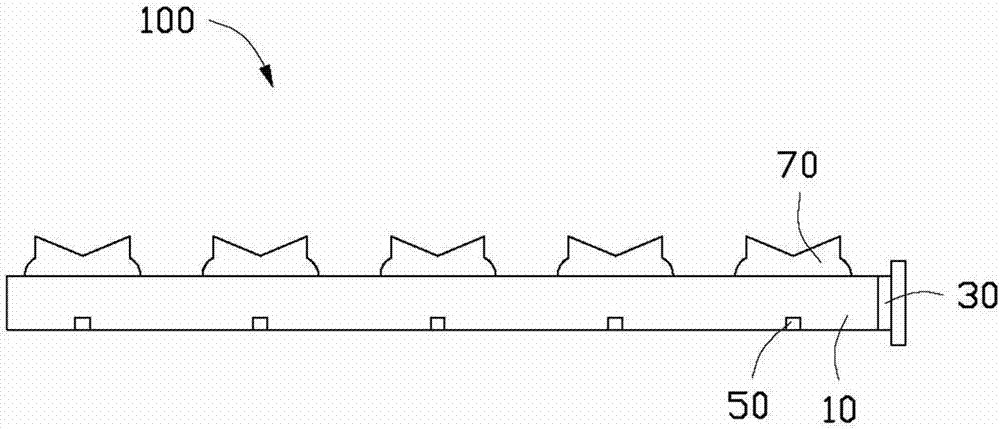

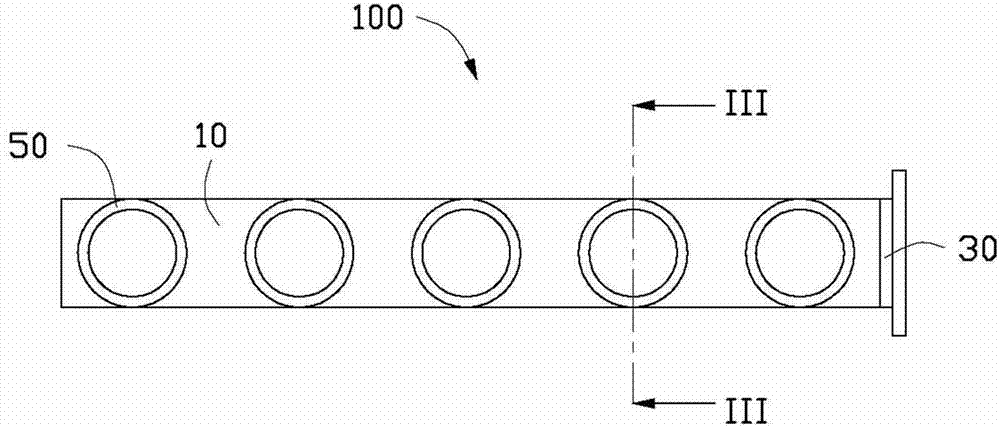

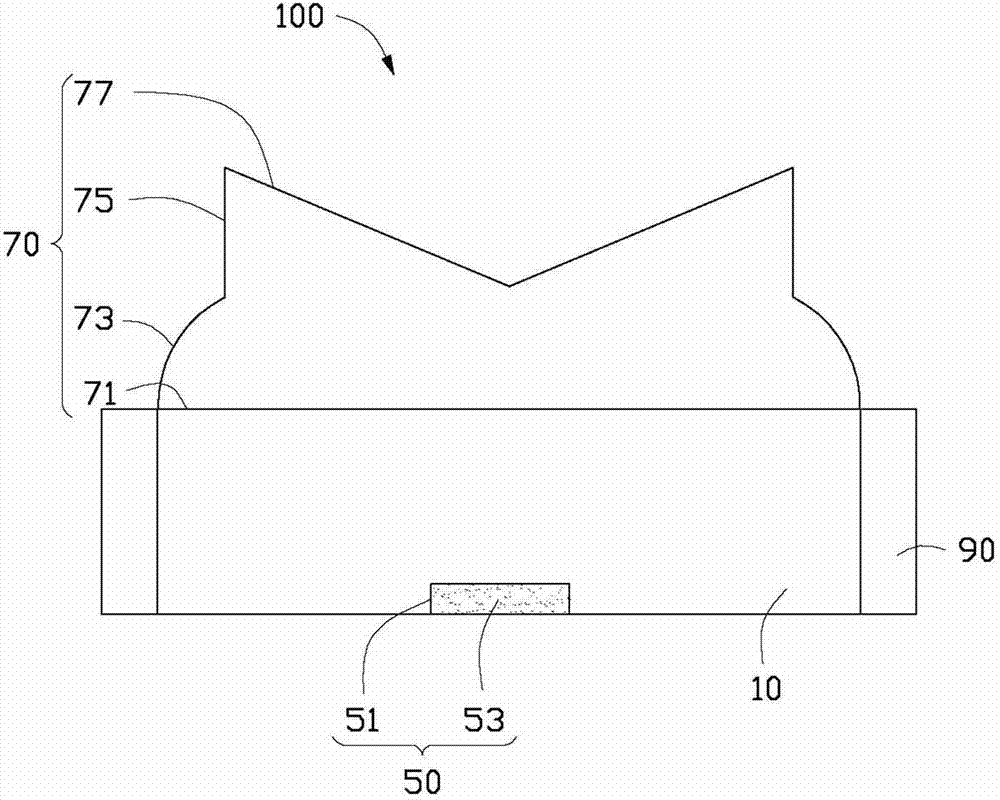

[0014] Such as figure 1 and figure 2 As shown, the side-type backlight module 100 of the first embodiment of the present invention includes a light guide plate 10, a light emitting diode 30 disposed at one end of the light guide plate 10, a plurality of dotted areas 50 disposed on the bottom surface of the light guide plate 10, A plurality of lenses 70 fixed on the top surface of the light guide plate 10 and facing the dot area 50 and two reflectors 90 fixed on the opposite sides of the light guide plate 10 (see image 3 ).

[0015] The light guide plate 10 is a long plate with uniform thickness for mixing the light emitted by the LEDs 30 . The bottom surface of the light guide plate 10 is parallel to the top surface thereof.

[0016] The grid dot regions 50 are arranged in parallel and at intervals along the longitudinal direction of the light guide plate 10 . Each dot area 50 extends along the transverse direction of the light guide plate 10 and runs through the entire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com