Novel crystal inorganic salt drying device

A drying device and inorganic salt technology, applied in the direction of drying solid materials, non-progressive dryers, drying, etc., can solve the problems of great influence on the shape of inorganic salt crystals, unstable product quality, uneven heating of materials, etc. Achieve the effect of small impact on shape, simple structure and easy agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

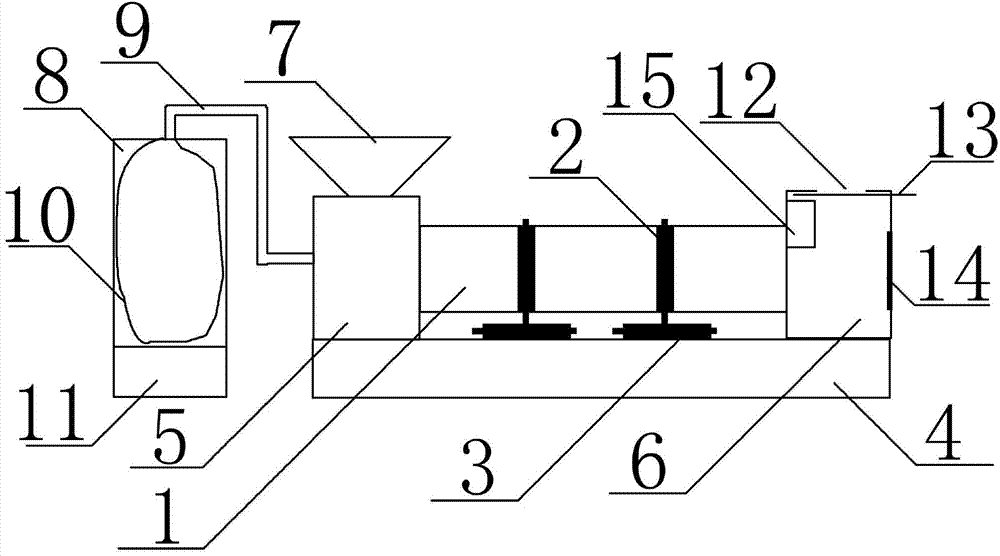

[0008] Below in conjunction with accompanying drawing, the present invention is described in further detail;

[0009] Such as figure 1 As shown, two rotating devices A2 are arranged on the drum 1, a rotating device B3 is connected under the rotating device A2, a base 4 is arranged under the rotating device B3, one end of the drum 1 is connected with the cavity 5, and the other end is connected with the discharge box 6 , the chamber 5 is provided with a feed hopper 7, and one side of the chamber 5 is provided with a dust collector 8, and the dust collector 8 and the chamber 5 are connected through a collection pipe 9, and the inside of the dust collector 8 is provided with a collection bag 10 And suction blower 11, suction blower 11 is positioned at collecting bag 10 outsides, offers an opening 12 on the discharge box 6, and described opening 12 place is provided with a push-pull plate 13, and discharge box 6 is provided with a cooling plate 14, discharge box 6 A fan A15 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com