A flip-type online outer diameter automatic measuring device

An automatic measurement and flipping technology, which is applied in the direction of measuring devices and instruments, can solve the problems of inaccurate feedback information, low degree of automation, and reduced detection accuracy in the manufacturing process, and achieve convenient and efficient measurement, high degree of automation, and reduced quantity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

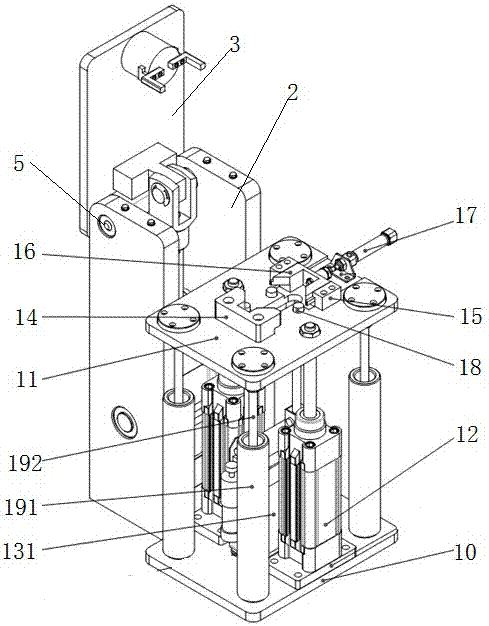

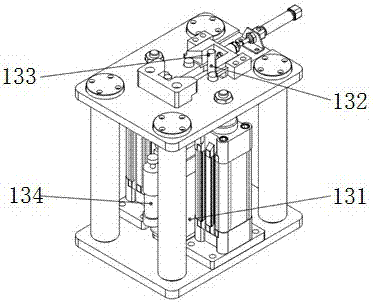

[0032] see figure 1 , a flip-type online outer diameter automatic measuring device of the present invention, comprising a flip-type clamping mechanism and a lift-type measuring mechanism arranged adjacently, the flip-type clamping mechanism is used The measuring mechanism is the core to realize the automatic measurement of outer diameter.

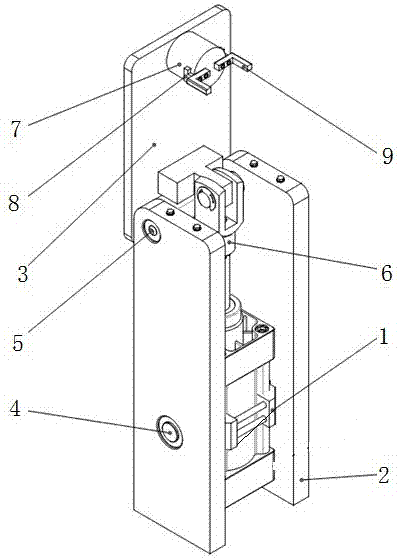

[0033] Among them, such as figure 2 As shown, the flip-type clamping mechanism includes: a flip cylinder 1, a pair of side plates 2, a flip cover 3 and a grabbing assembly. , and one end of the flip cover 3 is connected to the top of the side plate 2 through the rotation of the flip cover shaft 5. In this way, the push rod movement of the flip cylinder 1 drives the flip cover 3 to flip relative to the side plate 2. In order to make the flip more reliable and easy to implement, A joint 6 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com