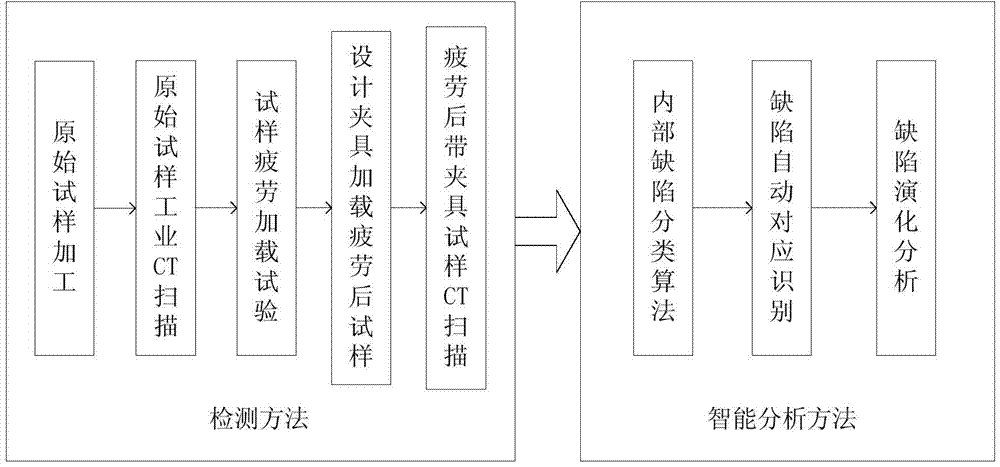

Method for detecting and analyzing internal defect evolution of metal casting in fatigue process

A technology for internal defects and metal castings, applied in the field of non-destructive testing of industrial CT technology and intelligent characterization of materials, can solve problems such as inability to evolve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0092] In order to better understand the method of the present invention, examples will be given below for detailed description.

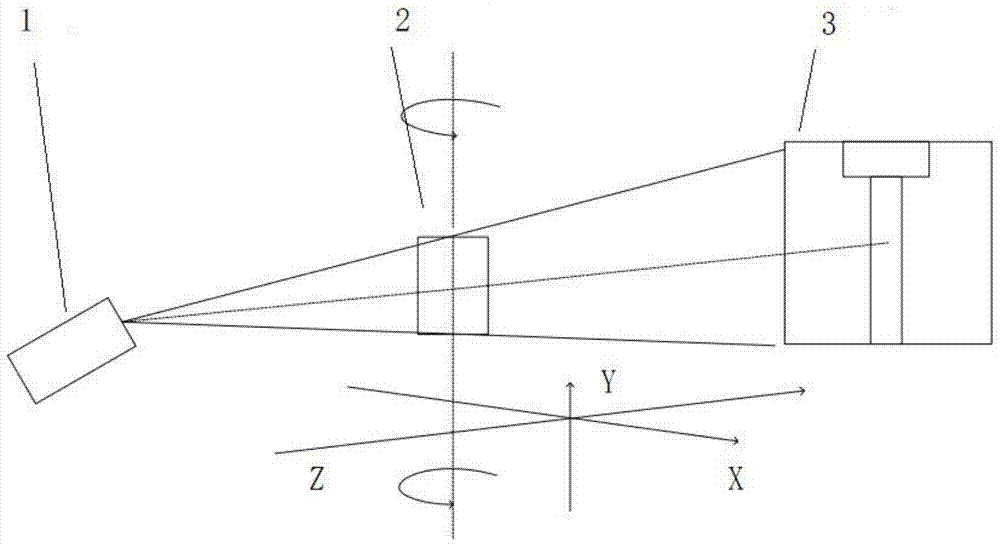

[0093] Taking the cast aluminum alloy material as an example, the sample is processed, and the metal sample before and after fatigue is scanned by 3D industrial CT, and the 3D industrial CT image is intelligently analyzed to obtain the evolution of the internal defects of the metal sample during the fatigue process .

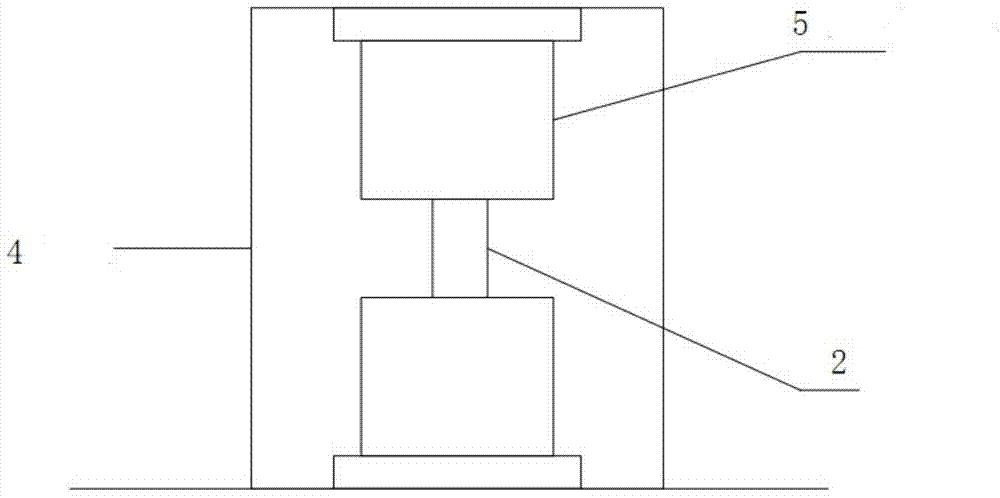

[0094] The first step is metal sample design.

[0095] Sampling the material of the high-speed rail gear box and processing it into a solid cylinder as the metal sample 2. The middle part of the metal sample 2 is thinner, so that in the subsequent fatigue test process, cracks are more likely to occur in the middle of the metal sample 2, which is beneficial to crack detection. The location is predicted. Metal sample 2 size such as Figure 9 As shown, before the test, the middle part of the metal sample was polished to remove the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com