Sandwich precision thermal controller for spatial optical remote sensor reflector

A space optical remote sensing and mirror technology, applied in optics, optical components, installation, etc., can solve the problems of general stability, uneven heating temperature of the mirror body, and poor temperature consistency between the mirror body and the supporting structure. Achieving the effect of fast response, good temperature control, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

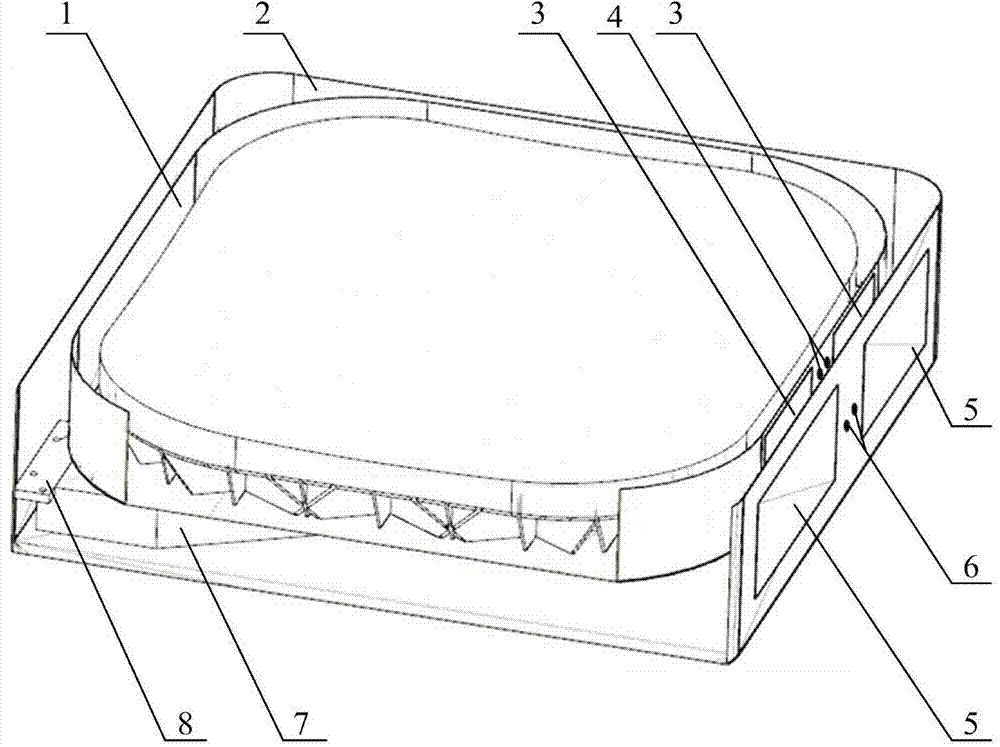

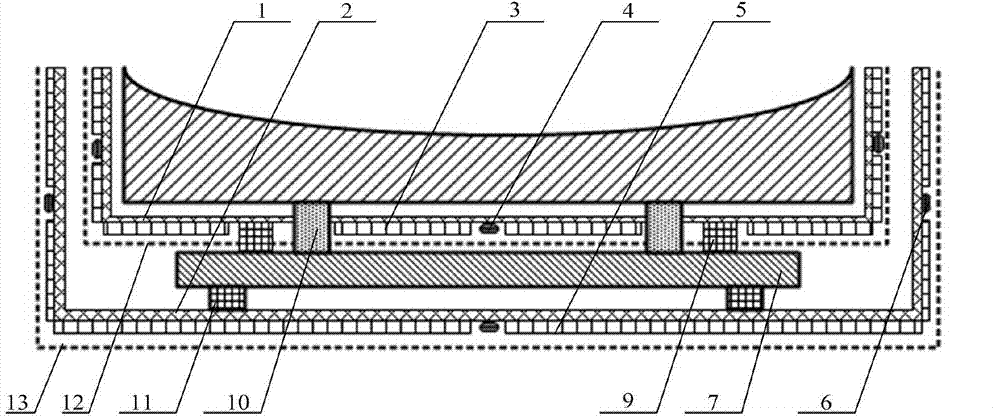

[0019] See attached figure 1 And attached figure 2 , the present invention is a sandwich type precision thermal control device for space optical remote sensor reflector, comprising inner layer temperature control device, outer layer temperature control device and reflector support structure, inner layer temperature control device and outer layer temperature control device The structures are the same, and the reflector support structure 7 is between the inner layer temperature control device and the outer layer temperature control device;

[0020] The inner layer temperature control device includes an inner radiator 1, an inner heat insulation pad 9, titanium alloy screws, an inner multilayer heat insulation assembly 12 and an inner layer temperature control circuit; the four side walls and the bottom of the outer surface of the inner radiator 1 are respectively Paste n inner layer temperature control loops, the inner layer temperature control loop includes two inner temperat...

specific Embodiment 2

[0032] The difference between this embodiment and Embodiment 1 is that a temperature control loop is pasted on the four side walls and the bottom of the outer surface of the inner radiator 1, and each temperature control loop uses two internal temperature sensors 4 and one internal heater. 3. The distance between the two inner temperature sensors 4 and the inner heater 3 is 3mm;

[0033] A temperature control circuit is pasted on the four side walls and the bottom of the outer surface of the outer radiator 2, and each temperature control circuit adopts two external temperature sensors 6 and one external heater 5, and the distance between the two external temperature sensors 6 and the heating plate The distance is 3mm.

[0034] Specific try method three:

[0035] The difference between this embodiment and Embodiment 1 is that one temperature control circuit is pasted on the four side walls and the bottom of the outer surface of the inner radiator 1, and each temperature contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com