Semiconductor structure and manufacturing method thereof

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as chip aluminum wire damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

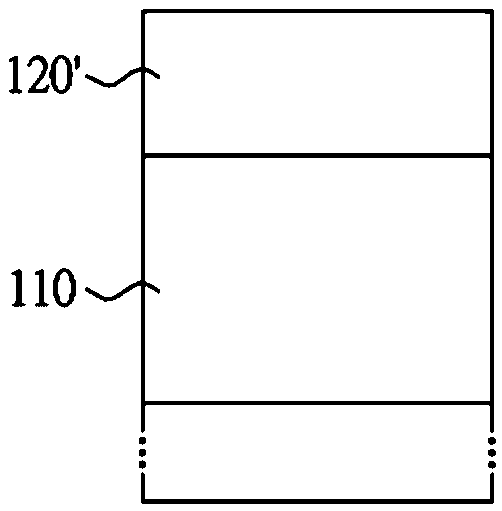

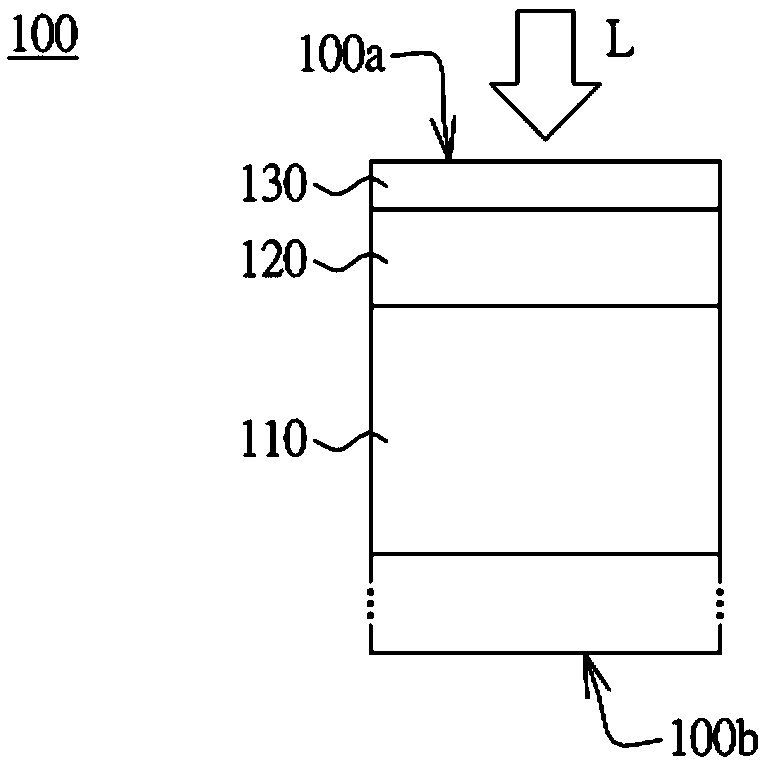

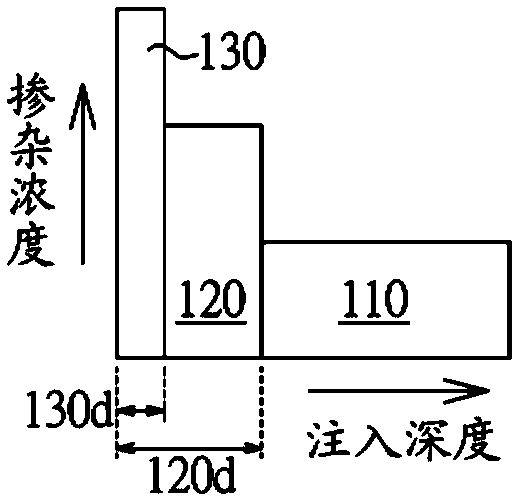

[0038] In the embodiment of the content of the present invention, in the manufacturing method of the semiconductor structure, the dopant of the semiconductor structure is activated by infrared light and green laser with specific pulse time and scanning speed, so that deep and shallow layers with different doping types can be achieved. Activation, and still have a clear P-N junction between the two, which can be applied to various types of components. The following is a detailed description of embodiments of the present invention with reference to the accompanying drawings. The same reference numerals are used in the drawings to designate the same or similar parts. It should be noted that the drawings have been simplified to clearly illustrate the content of the embodiments, and the detailed structures proposed in the embodiments are for illustration purposes only, and are not intended to limit the protection scope of the present invention. Those with ordinary knowledge can mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com