Underwater photoelectric separating cabin

A technology of photoelectric separation and photoelectric composite cable, applied in the direction of cable joints, etc., can solve the problems of sealing reliability and structural strength contradiction, and achieve the effect of facilitating construction adjustment, light weight and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

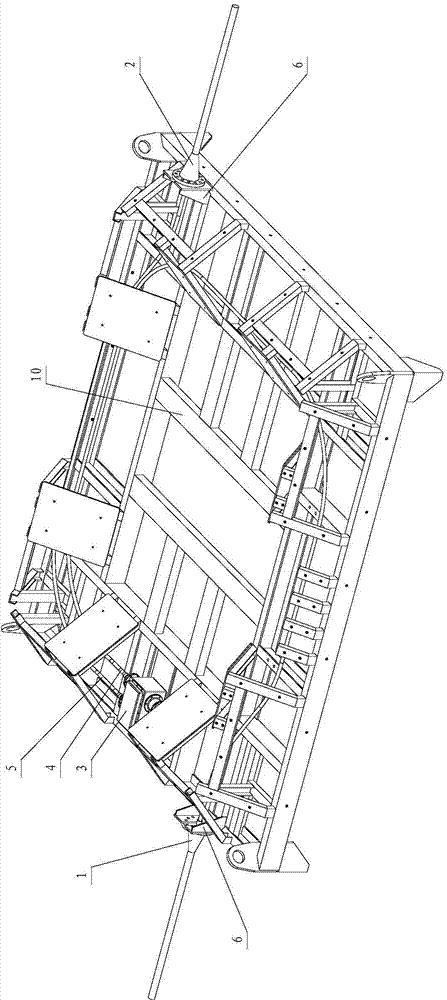

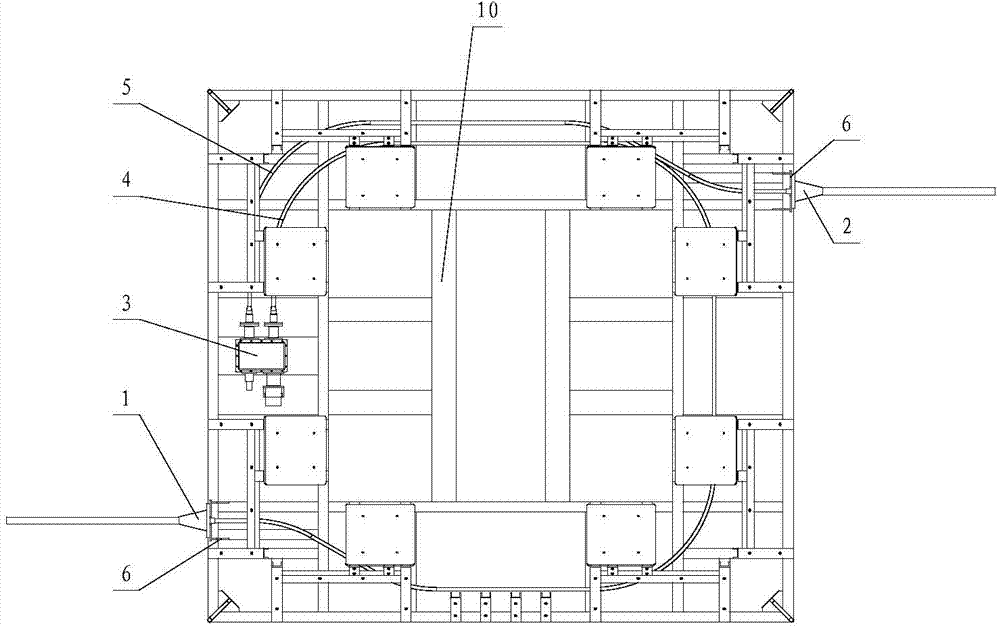

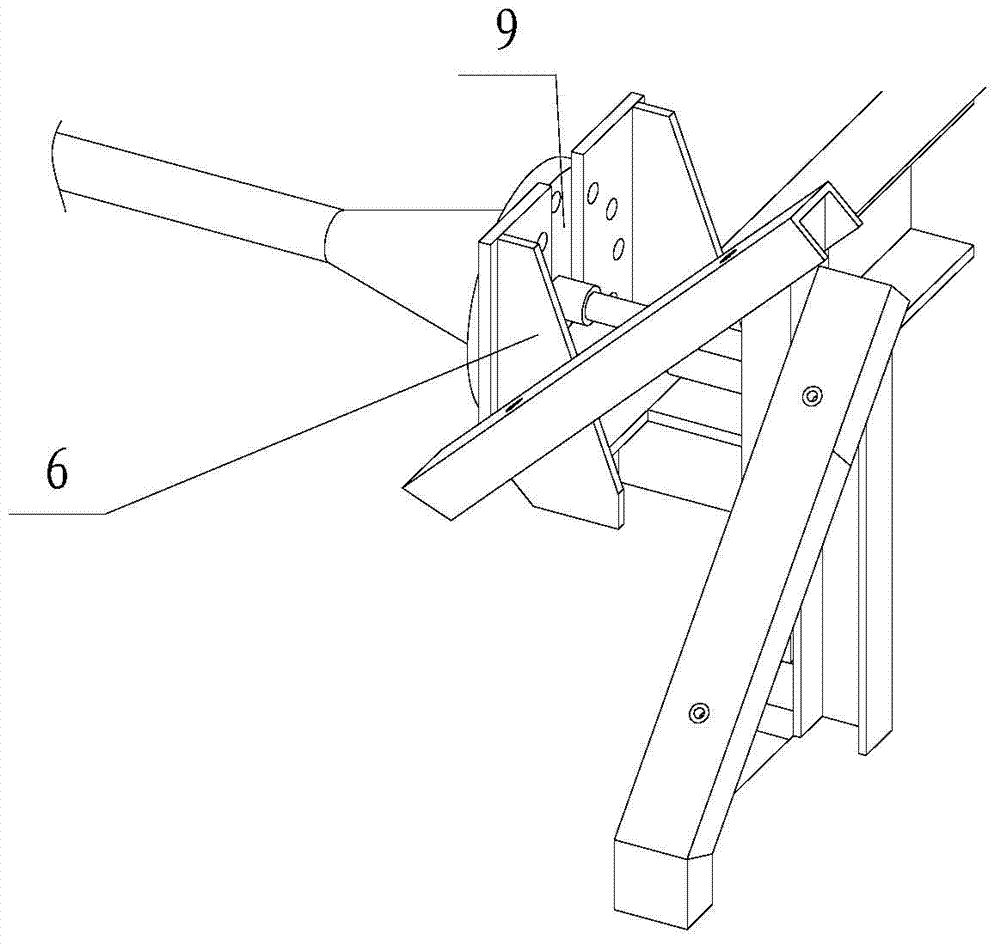

[0020] Such as figure 1 , figure 2 As shown, the present invention includes a structural frame 10, a submarine cable load-bearing end and a photoelectric separation cabin 3, wherein the submarine cable load-bearing end is installed on the structural frame 10, and a flange 6 is fixed on the structural frame 10, and a flange 6 is fixed on the flange 6. A U-shaped opening is provided to facilitate the disassembly and maintenance of the submarine cable. The load-bearing end of the submarine cable is provided with a butt flange 9, and the steel wire armored sheath of the outer layer of the submarine cable is pressed against the butt flange 9, and the butt flange 9 is fixed to the U-shaped opening of the flange 6 by bolts. The number of the load-bearing end of the submarine cable is the same as that of the flange 6, which is one or more; two flanges 6 are fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com