Process for producing a cosmetic product having a surface with a decorative embossed and/or debossed pattern

A technology for cosmetics and cosmetics, applied in the production of cosmetics and lipsticks with decorative relief patterns and/or concave patterns on the surface, which can solve the problems of expensive and complicated methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The same reference numbers are used to designate the same or similar elements in different drawings.

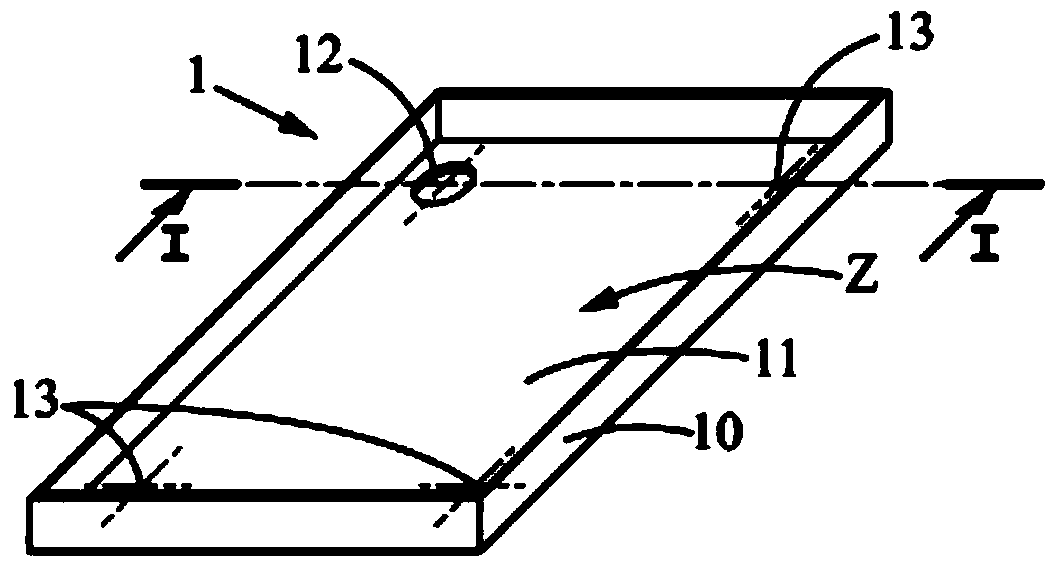

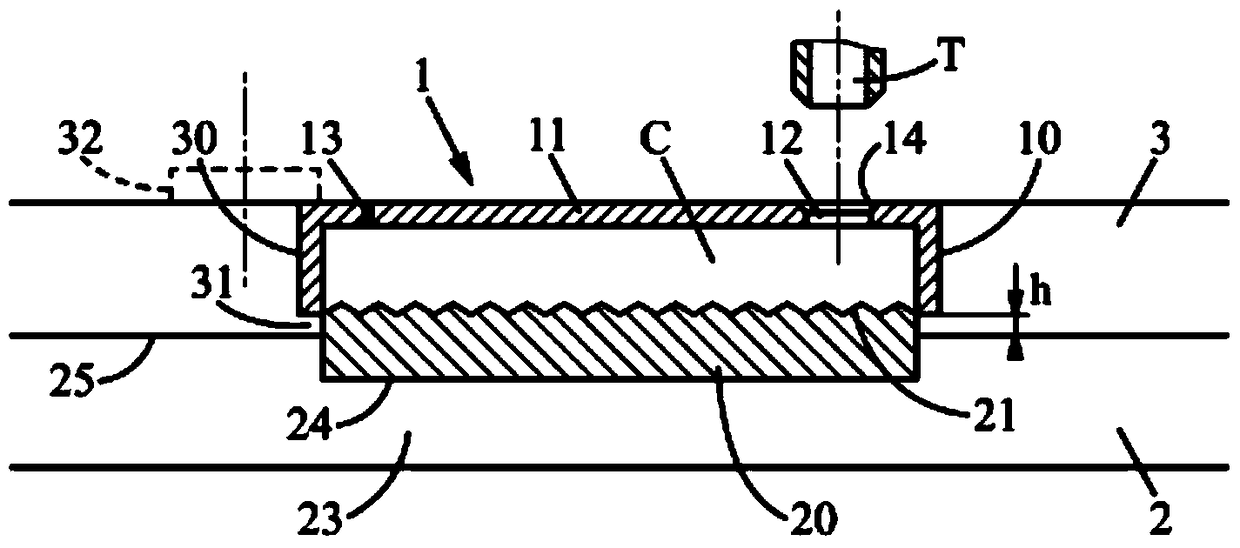

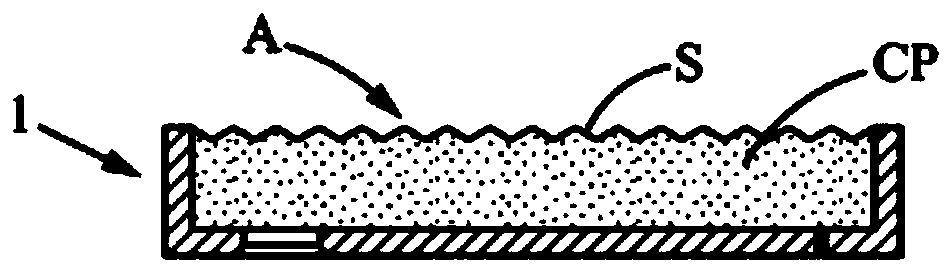

[0062] exist figure 1 In , a container 1 as used in the production method of the first embodiment of the present invention is shown. The cross-sectional shape of the container is rectangular or substantially rectangular and comprises a bottom 11 and a peripheral wall 10 delimiting a filling zone Z for containing a hot-fill cosmetic product CP such as lipstick, lipstick, eyeliner, foundation , or any other cosmetic that can be heat infused.

[0063] In this first embodiment, the container 1 used has a single filling zone Z bounded by the bottom 11 and the peripheral wall 10 of the container 1, extending substantially vertically from the bottom 11 of said container 1 to the edge of its peripheral wall . Associated with this filling area is a filling hole 12 and three ventilation holes 13 formed on the bottom 11 of the container 1 .

[0064] Advantageously, the fillin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com