Method for producing Li-ion battery module and corresponding Li-ion battery module

A technology of lithium-ion batteries and battery modules, which is applied in the direction of large-size batteries/battery packs, small-size batteries/battery packs, and isolation of batteries from their environment, and can solve problems such as different battery densities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

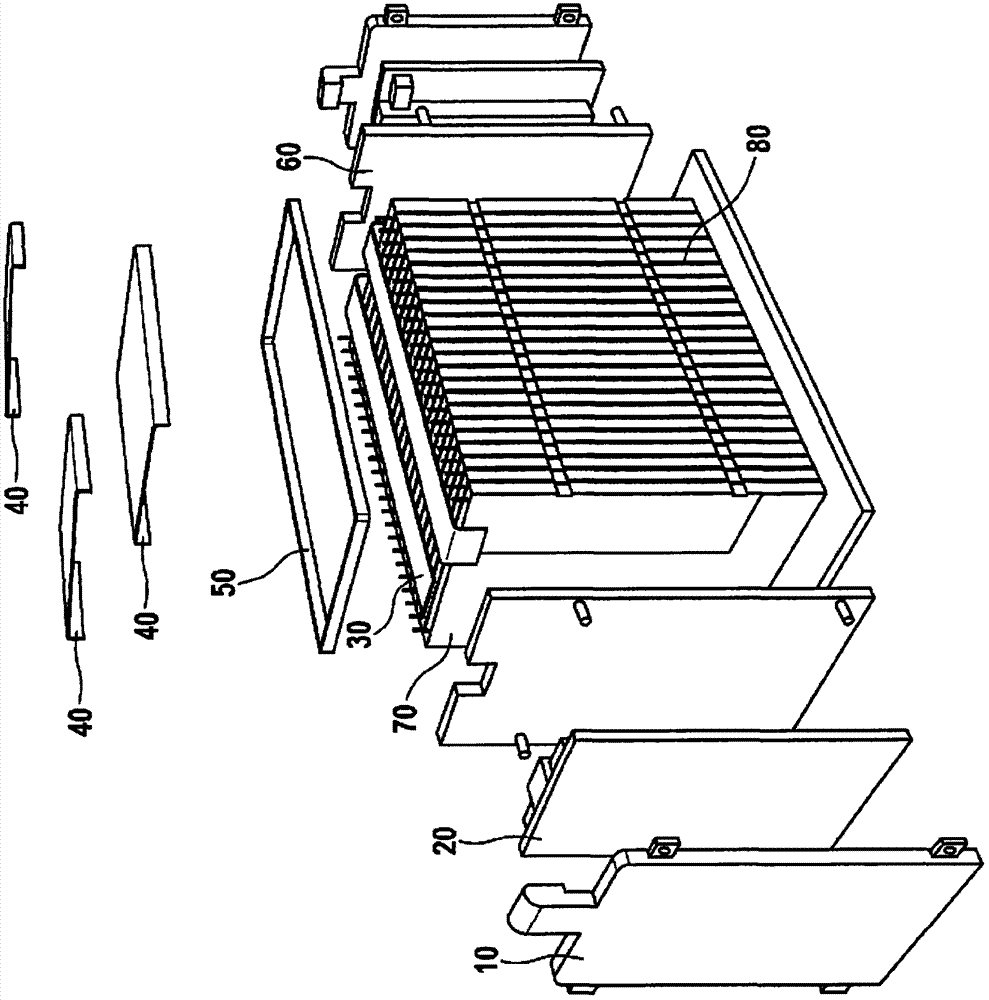

[0025] image 3 A schematic diagram of an exemplary arrangement for constructing a mechanically pressed battery is shown.

[0026] exist image 3 Among them, reference numeral 10 denotes the cover plate of the electronic device, 20 denotes the control electronics, 30 denotes the laser-welded connection rail, 40 denotes the connection cover, 50 denotes the pressure strap, 60 denotes the pressure plate, 70 denotes the prismatic lithium-ion battery And reference numeral 80 designates a cooling body.

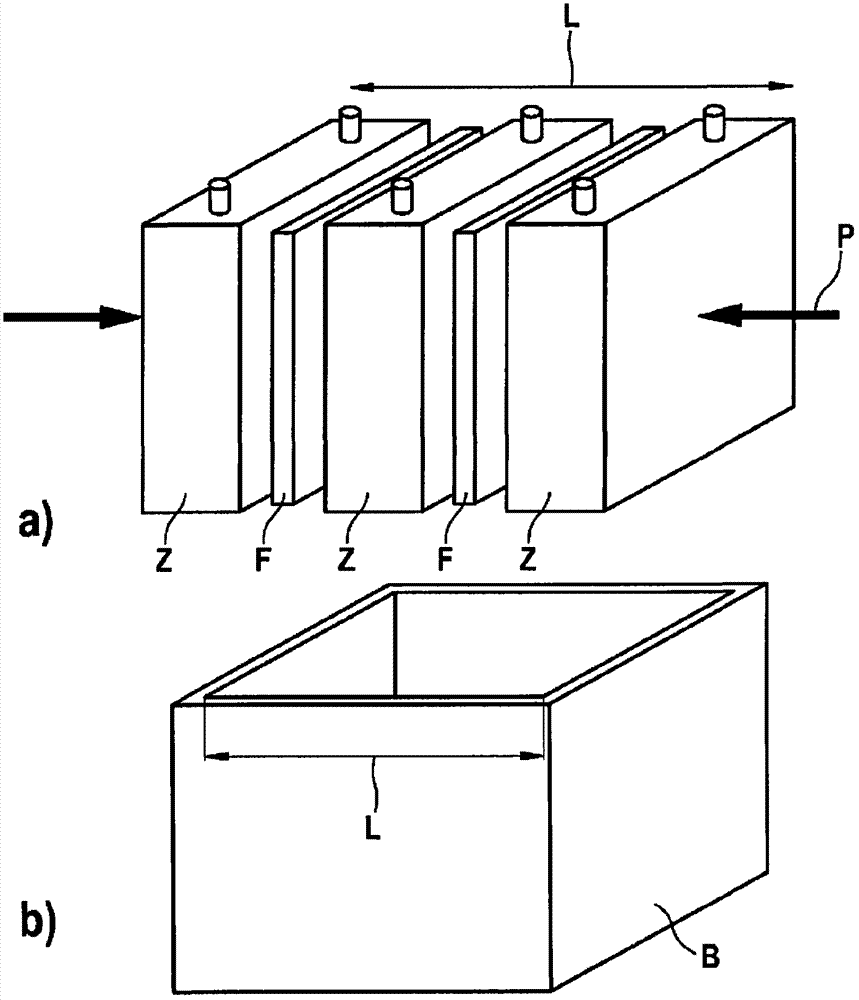

[0027] figure 1 a is a schematic view of a lithium-ion battery module produced according to an embodiment of the method according to the invention and figure 1 b is a schematic illustration of the housing of a lithium-ion battery module produced according to one embodiment of the method according to the invention.

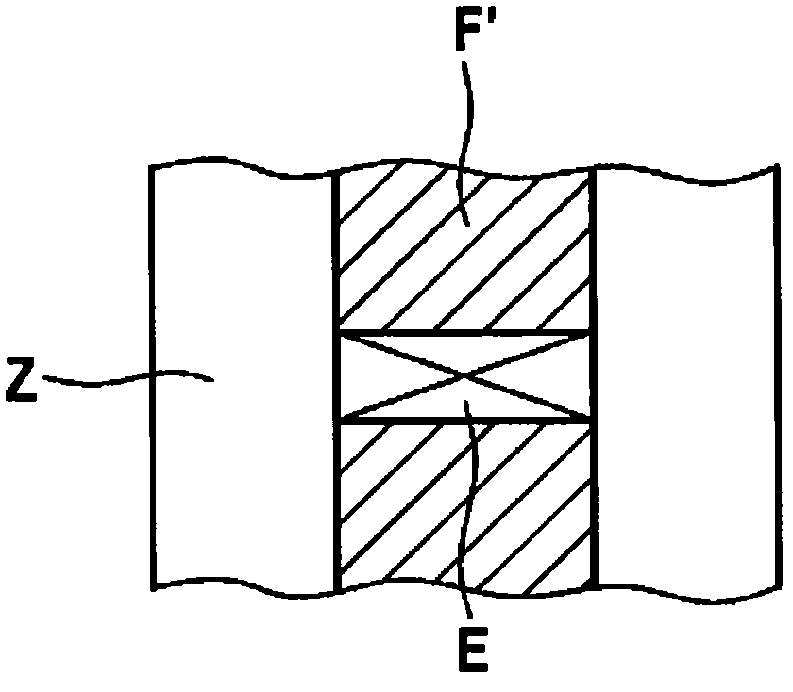

[0028] exist figure 1 In a) and b), reference sign Z denotes a battery of the battery module. The reference F designates the elastic-plastic membrane and L the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com