Food baking method and device

A baking method and baking device technology, which are used in food ovens, baking, food science, etc., can solve the problems of food bubbles, insufficient gloss, and food not being cooked, so as to ensure smoothness and flatness, and avoid air bubbles. , the effect of eliminating bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

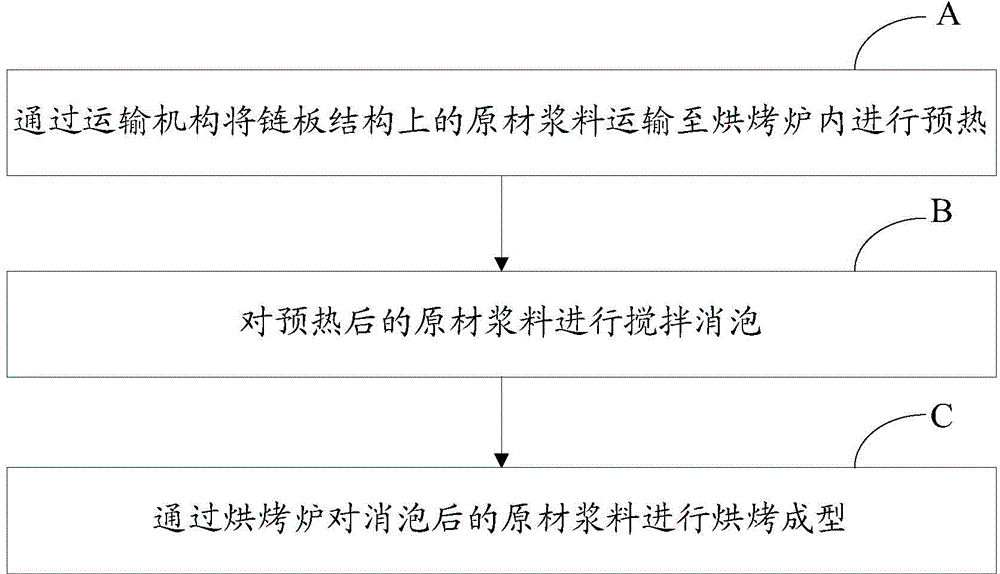

[0040] The present invention also provides a food baking method, comprising the following steps:

[0041] In step A, the raw material slurry on the chain plate structure is transported to the oven for preheating by the transport mechanism; the preheating temperature is 50-200° C. (Celsius), and the preheating time is 1-5 minutes (minutes). The raw material slurry can be mixed with flour, food additives and water according to a predetermined ratio to form a fluid paste. This is the prior art for preparing the raw material slurry, and the specific process will not be repeated.

[0042] In step B, the preheated raw material slurry is stirred and defoamed, and the stirring time is 10-300s (seconds). After the slurry enters the furnace body and is preheated for a period of time, the preheated raw material slurry can be taken out of the baking furnace, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com