Automatic spraying machine

An automatic, main-frame technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of physical health injuries of operators, poor product surface treatment effects, and difficult processing time, etc. To achieve the effect of ensuring physical health, meeting time requirements, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

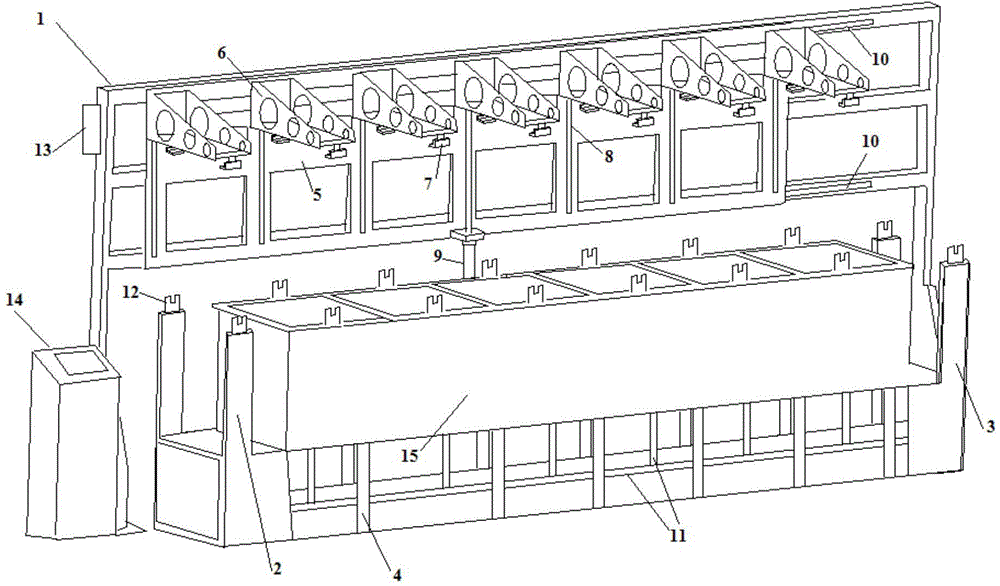

[0011] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0012] see figure 1 , the automatic dehydration machine of the embodiment of the present invention comprises a support main frame 1, an input frame 2, a take-out frame 3, a groove frame 4, a product transfer main frame 5, a fixed beam 6, a pneumatic fixing clip 7, a linear slide rail-8, and a cylinder 19. Linear slide rail 210. Water injection and drainage pipe 11. Product fixing frame 12. Working indicator light 13. PLC controller 14. Tank body 15.

[0013] The supporting main frame 1 is made of aluminum alloy material, which is sturdy and durable, and basic supports are installed under the two sides thereof, so that the supporting main frame 1 can stand stably.

[0014] The support main frame 1 is provided with two linear slide rails 10 along the horizontal direction.

[0015] Product transfer main frame 5 links to each other with supporting main fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com