Twist drill

A twist drill and cutter head technology, applied in twist drills, conical drills, drilling tool accessories, etc., can solve problems such as affecting the processing effect of twist drills, unfavorable production, and scratching the processing holes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

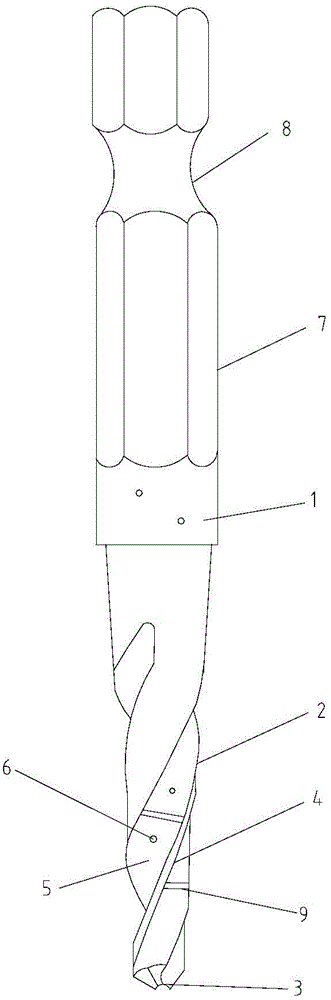

[0012] As shown in the figure, the twist drill includes a handle 1 and a cutter head 2. The handle 1 is set above the cutter head 2 and connected to the cutter head 2. The bottom of the cutter head 2 is conical, and the angle between the two sides of the conical section is 135°, the bottom of the cone is provided with an arc-shaped groove 3 for chip removal. The arc-shaped groove 3 can accommodate small chips in the chip removal, preventing the fine chips from being discharged and affecting the quality of the processed surface. A number of spiral cutting edges 4 are provided, and a spiral chip removal groove 5 matched with the cutting edge 4 is provided between each two cutting edges 4, which is beneficial to chip removal. 9. It can cut off the spiral chips and prevent the chips from winding on the workpiece. The cutting edge and the spiral chip removal groove 5 are connected with the arc groove 3. There is a heat dissipation channel 6 on the tool handle 1 and the cutter head 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com