Parabolic side plate spring framework smooth joint

A parabolic, edge plate technology, applied in the directions of manipulators, manufacturing tools, joints, etc., can solve problems such as the need to improve the dynamic responsiveness, the dynamic response to be improved, and the uneven force of the leaf spring, so as to facilitate the analysis and calculation, and improve the dynamic response. Sex, the effect of avoiding contact interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

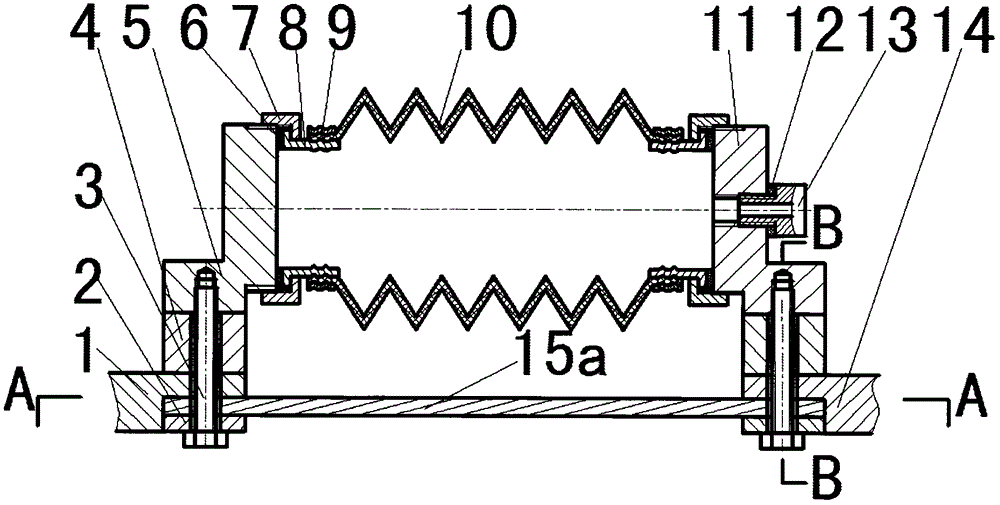

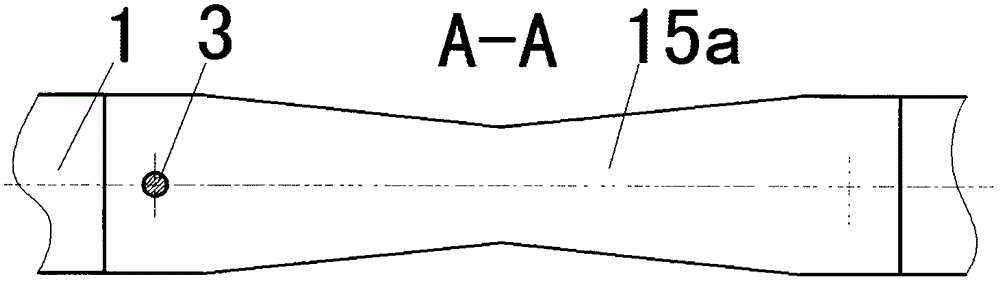

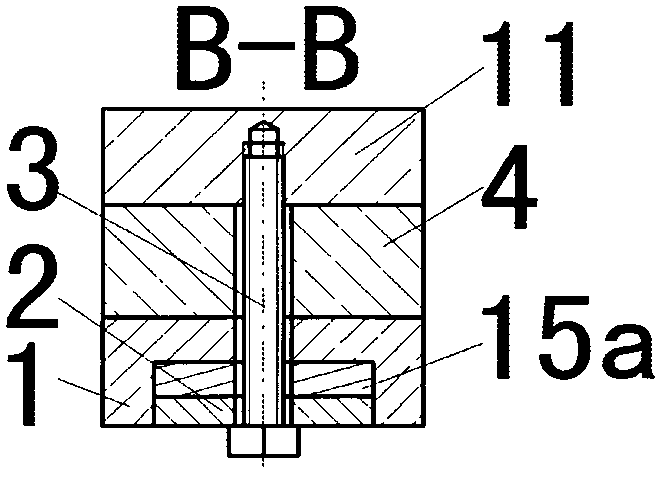

[0037] Below the present invention is combined with attached Figure 14 The first implementation of the scheme is further described:

[0038]In Scheme 1, the two ends of the elastic bellows 10 are fixed on the pipe joint 8 through the pressure piece 9, and the pipe joints 8 at both ends of the bellows are respectively connected with the headstock 5 and the tailstock 11, and are locked by the lock nut 7, with a Gasket 6 is sealed to form a gas cavity. There is an air inlet on the tailstock 11, and the air inlet pipe joint 13 is fixed on the tailstock 11 through the sealing ring 12. The headstock 5 and the tailstock 11 are respectively fixed with the head section 1 and the tail section 14 through the adjustment cushion block 4 . There are positioning pins on the upper and lower surfaces of the adjustment cushion block 4 to ensure the mutual positioning between the headstock 5 and the head section 1 as well as the tailstock 11 and the tail section 14. The two ends of the trape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com