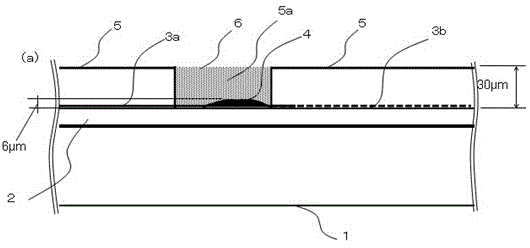

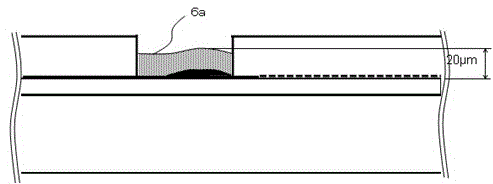

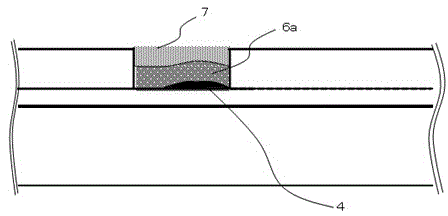

Thermo-sensitive printing head for automatic deposited carbon removal and manufacturing method

A thermal printing head, technology of manufacturing method, applied in printing and other directions, capable of solving problems such as shallow depth and small width of groove 6a

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with embodiment the patent of the present invention is described further:

[0021] Embodiment 1

[0022] The thermal print head includes a substrate made of insulating material. A base layer (bottom glaze glass) is made on the substrate, and then wire electrodes are formed on the surface of the substrate and the base layer. The wire electrodes are divided into individual electrodes and common electrodes. The wire electrodes formed on the wire electrodes The heating resistor strip along the main printing direction, one end of individual electrodes is connected to the heating resistor strip along the sub-printing direction, the other end is connected to the control IC, one end of the common electrode is connected to the heating resistor strip along the sub-printing direction, and the other end is connected to the heating resistor strip along the sub-printing direction. One end is connected with the wire pattern, and the above part constitutes the cera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com