Approximately closed food processor

A food processing machine and machine body technology, which is applied to heating devices, kitchen utensils, household utensils, etc., can solve the problems of increasing the difficulty of cleaning the pulp receiving cup, the inability to ensure that the pulp is fully boiled, and the taste of soybean milk cannot be guaranteed, so as to avoid overflow. Pulping or pressure pulping phenomenon, good cooking effect, and improved crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

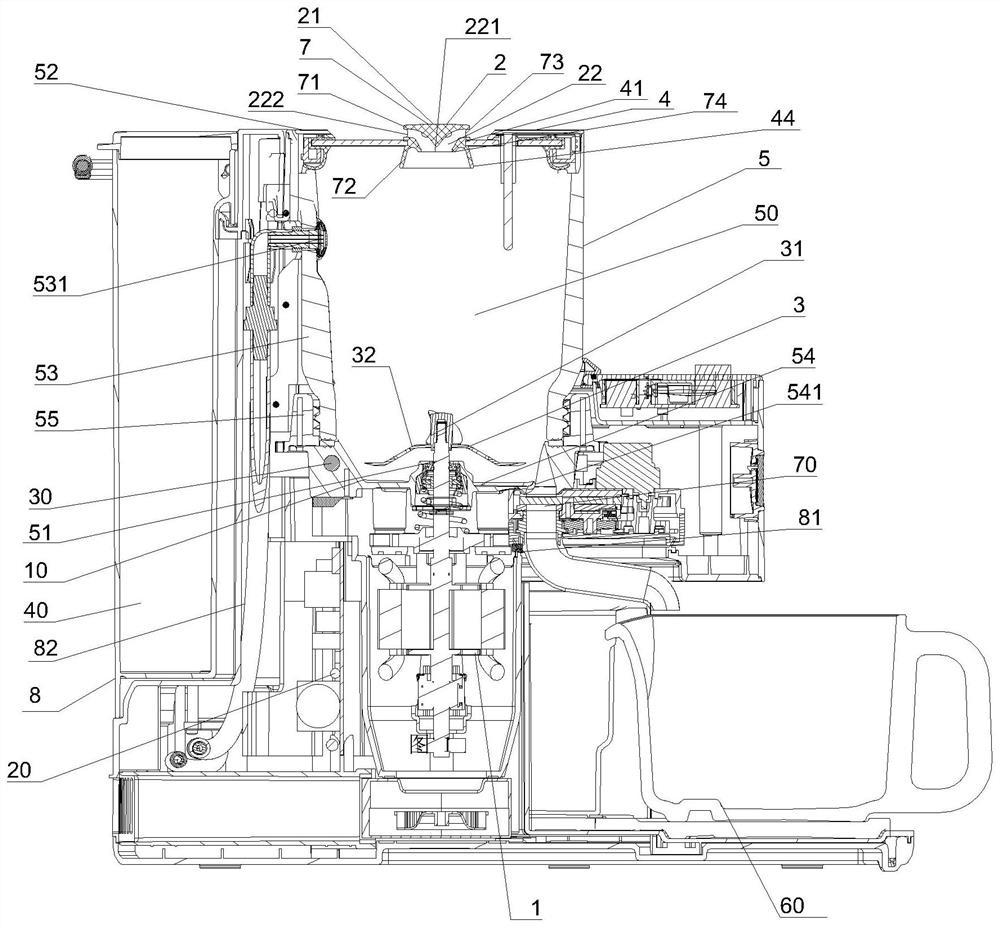

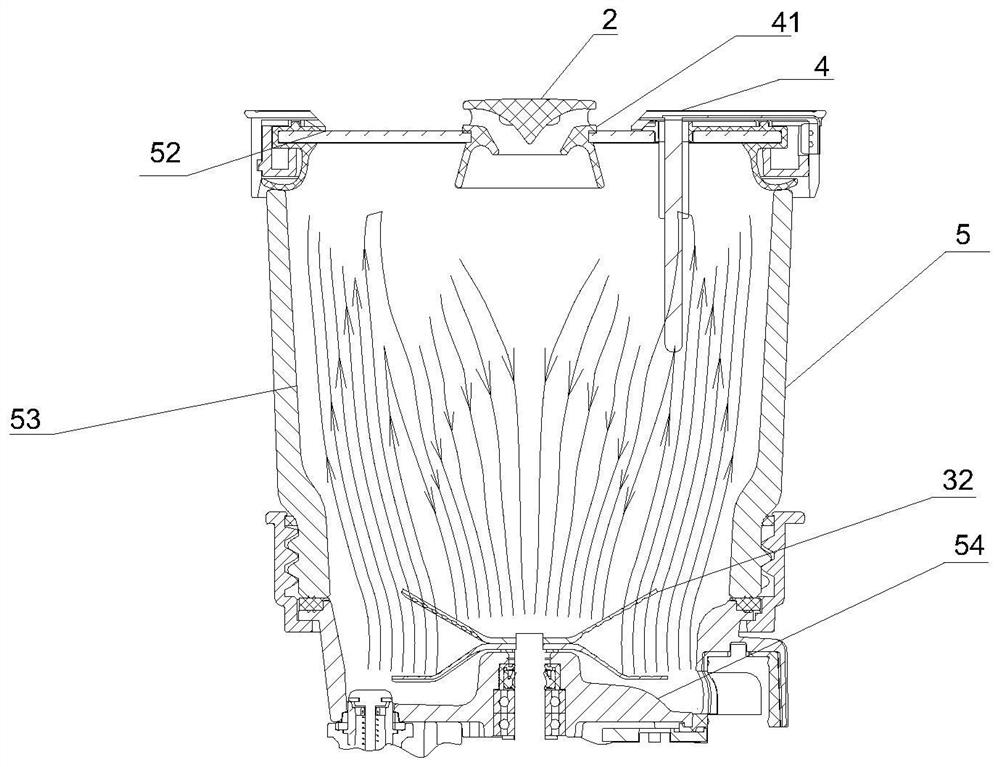

[0053] As the first embodiment of the food processor of the present invention, as Figure 1 to Figure 3 As shown, it includes a machine body 8, a control unit 20, a heating unit 30 and a crushing unit 10. The machine body 8 includes a frame 81 and a frame 82. The control unit 20 and the crushing unit 10 are arranged on the frame 82. The fuselage 82 is provided with a water tank 40, the control unit 20 controls the work of the crushing unit 10 and the heating unit 30, the crushing unit 10 includes a motor 1, a crushing assembly 3 and a crushing container, and the motor 1 drives the crushing assembly 3 rotation, the crushing assembly 3 includes a knife shaft 31 and a crushing knife 32 arranged at the top of the knife shaft 31, and the crushing container includes a first container body 5 with an inner cavity and a fastening body 4 fastened on the first container body 5 , the knife shaft 31 extends into the first container body 5 through the through hole 51 at the bottom of the fi...

Embodiment approach 2

[0068] As the second embodiment of the food processor of the present invention, as Figure 4 to Figure 7 As shown, the difference from Embodiment 1 is that the volume of the pulping cavity and the structure and parameters of the exhaust device are different, and the heating unit is also different.

[0069] In this embodiment, the fastening body 4 is a cover body, and the cover body is a double-layer cover. The center of the cover body is provided with an upward in-line protrusion 42, and the center of the protrusion part is provided with a vent hole 41. The vent hole 41 is set through the raised portion 42 and the cover body 41 in turn. The vent hole 41 includes a rectangular section 411 with rounded corners and a circular section 412 below. Fixed sleeve 43, the outer wall of the fixed sleeve 43 is installed in the air hole 41, and closely fits with the air hole 41, the shape of the fixed sleeve 43 is consistent with the air hole 41, and the fixed sleeve 43 includes a belt arr...

Embodiment approach 3

[0077] As the third embodiment of the food processor of the present invention, as Figure 8 and Figure 9 As shown, the difference from the second embodiment is that the volume of the pulping cavity and the structure and parameters of the exhaust device are different, and the heating unit is also different.

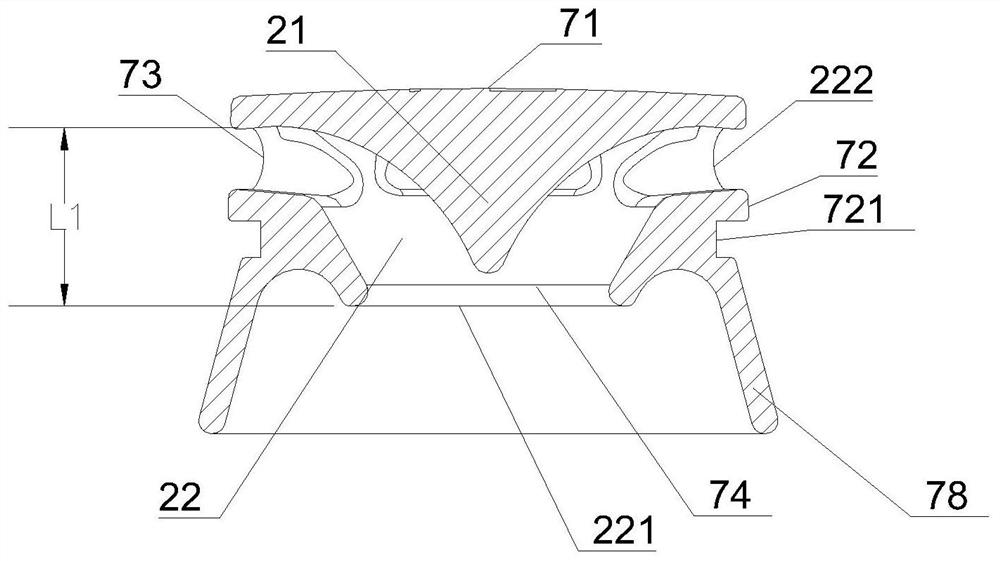

[0078] In this embodiment, consistent with Embodiment 2, the fastening body is a cover body, the cover body is a double-layer cover, and the center of the cover body 4 is provided with a vent hole 41, and the vent hole 41 is closely attached to A fixed sleeve 43 is provided together. The difference from the second embodiment is that the fixed sleeve 43 extends downward from the air hole 41 to form an annular enclosure 44. The exhaust device 2 is detachably installed in the fixed sleeve 43 and against At the limit step 433, the exhaust device is a silica gel plug 7, the silica gel plug 7 is a rectangular block with rounded corners, and the side wall 72 of the rectangular ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com