Electromagnetic type conveying device for blades

A transmission device and electromagnetic technology, applied in the field of electromagnetic transmission device, can solve the problems of hidden dangers and high equipment costs, and achieve the effects of reducing hidden dangers, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

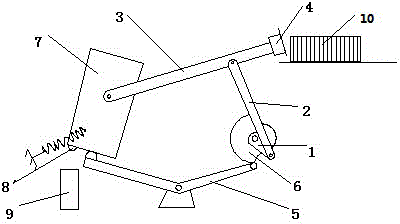

[0013] The reference signs in the description of the drawings are: linkage plate 1, push rod 2, feed rod 3, electromagnet 4, swing rod 5, cam 6, support block 7, touch switch 8, convex part 9, blade 10.

[0014] Such as figure 1 As shown, the technical solution provides an electromagnetic transmission device for blades, including a transfer device and a lever-type transmission device, and the transfer device includes a linkage mechanism composed of a linkage plate 1, a push rod 2 and a feed rod 3, The two ends of the push rod 2 are respectively hinged on the linkage plate 1 and the feed rod 3 , and the end of the feed rod 3 is fixedly equipped with an electromagnet 4 . The lever type transmission device includes a swing rod 5, a cam 6 and a support block 7, the swing rod 5 is in a curved structure, and its inflection point is a hinge point, and the two ends of the swing rod 5 are respectively connected with the cam 6 and the support block 7, One end of the feeding rod 3 is hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com