Method for recycling asphalt from asphalt mixture

A kind of asphalt mixture, the technology of recovering asphalt, applied in the processing of tar asphalt/petroleum asphalt/natural asphalt, processing tar asphalt/petroleum asphalt/natural asphalt by heating, processing tar asphalt/petroleum asphalt/natural asphalt by distillation, etc. It can solve problems such as uneven heating, asphalt disturbance, and the influence of asphalt aging, and achieve the effects of improving recovery efficiency, improving heating efficiency, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0030] Example 1:

[0031] A method for recovering asphalt from asphalt mixture, comprising the following steps:

[0032] Step 1: According to the test method of T0722-1993 in "Asphalt and Asphalt Mixtures for Highway Engineering" JTG E20-2011, the asphalt solution is extracted from the asphalt mixture;

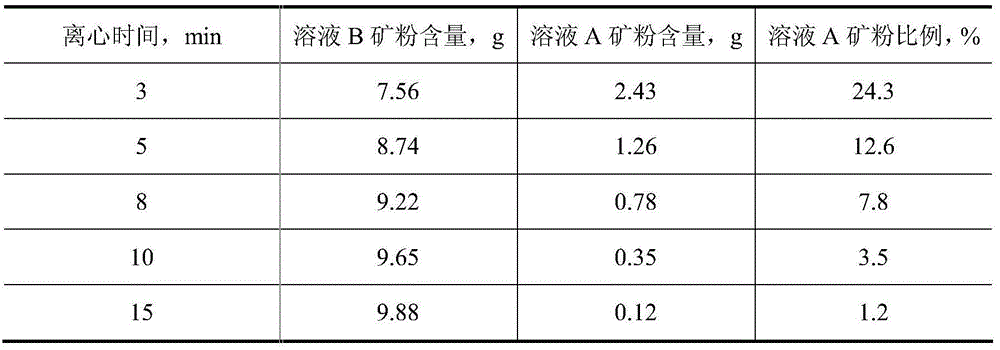

[0033] Step 2: Centrifuge the extracted bitumen solution for 20min at a speed of 4200r / min, and extract the upper layer solution with a pipette for use;

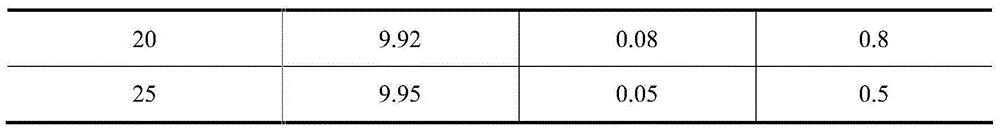

[0034] Step 3: Put the extracted upper layer solution into the microwave heating device, set the temperature of the microwave heating device to 100°C, and inject protective gas into the bottom of the flask at the same time, the initial gas flow rate is 800ml / min, in the microwave heating device, the solution The heating rate is faster, and the set temperature can be reached within 3 minutes. When the temperature of the flask reaches the set temperature, increase the ventilation rate to 1500ml / min and continue to distill f...

Example Embodiment

[0035] Example 2:

[0036] A method for recovering asphalt from asphalt mixture, comprising the following steps:

[0037] Step 1: According to the test method of T0722-1993 in "Asphalt and Asphalt Mixtures for Highway Engineering" JTG E20-2011, the asphalt solution is extracted from the asphalt mixture;

[0038] Step 2: Centrifuge the extracted asphalt solution at a speed of 4000 r / min, and extract the upper layer solution with a pipette for use;

[0039] Step 3: Put the extracted upper layer solution into a microwave heating device, set the temperature of the microwave heating device to 90°C, and inject protective gas into the bottom of the flask at the same time, and the initial gas flow rate is 850ml / min. In the microwave heating device, the heating rate of the solution is fast, and the set temperature can be reached within 3 minutes. When the temperature of the flask reached the set temperature, the ventilation rate was increased to 1550ml / min, and the distillation was c...

Example Embodiment

[0040] Example 3:

[0041] A method for recovering asphalt from asphalt mixture, comprising the following steps:

[0042] Step 1: According to the test method of T0722-1993 in "Asphalt and Asphalt Mixtures for Highway Engineering" JTG E20-2011, the asphalt solution is extracted from the asphalt mixture;

[0043] Step 2: Centrifuge the extracted asphalt solution at a speed of 4100 r / min, and extract the upper layer solution with a pipette for use;

[0044] Step 3: Put the extracted upper layer solution into the microwave heating device, set the temperature of the microwave heating device to 95°C, and inject protective gas into the bottom of the flask at the same time, the initial gas flow rate is 750ml / min, in the microwave heating device, the solution The heating rate is fast, and the set temperature can be reached within 3min. When the temperature of the flask reaches the set temperature, the ventilation rate is increased to 1450ml / min, and the distillation is continued for 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com