Spinning system and spinning method of high-strength DTY composite yarn

A spinning system and composite yarn technology, applied in the field of spinning, can solve the problem that the strength of composite yarn is difficult to reach military clothing, etc., and achieve the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

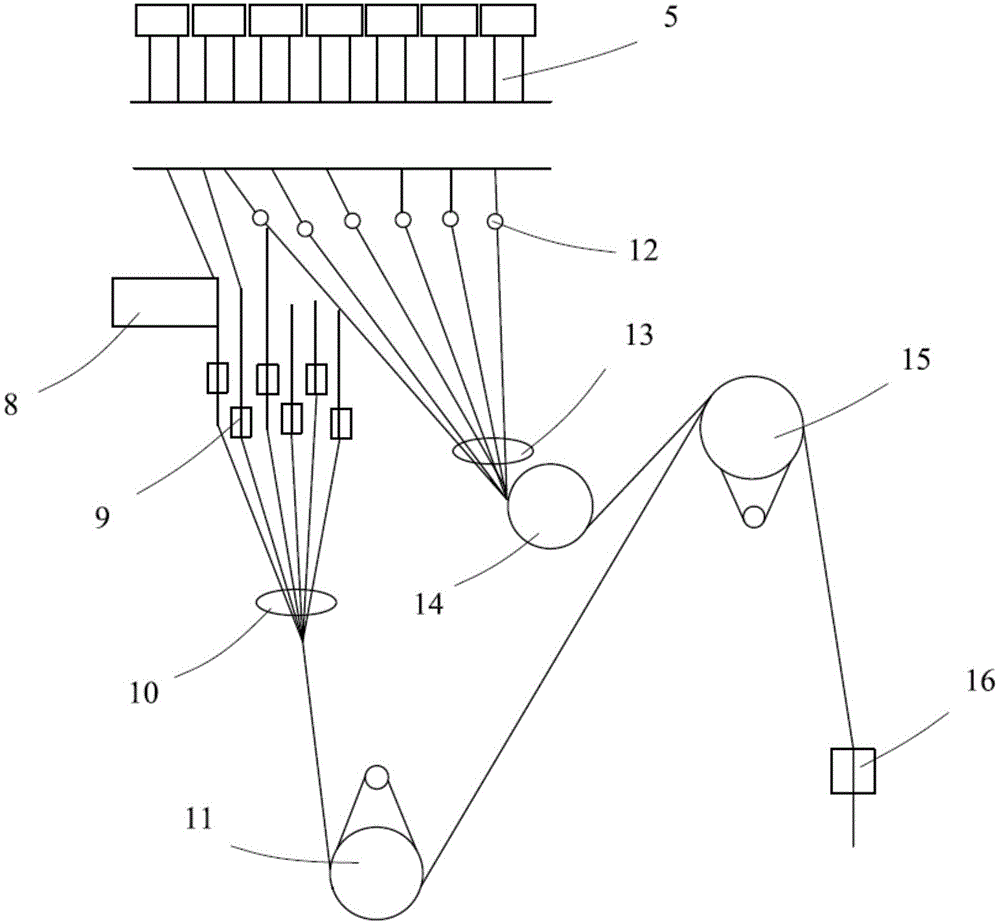

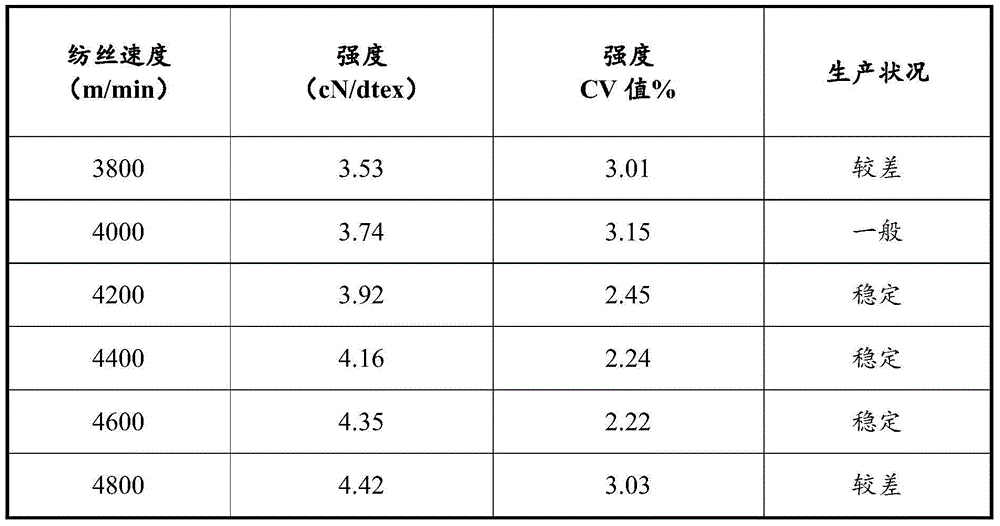

[0020] DTY composite yarn is generally made of a POY yarn which is false twisted and drawn and then plied with a FDY yarn. To improve the strength of DTY, the strength of FDY must be increased first, and then POY should be adjusted; the adjusted POY is twisted and drawn separately according to the original DTY composite yarn process, and the DTY yarn and FDY produced together are tested for strength and elongation. The strong waveform of this single DTY is basically the same as the undulation of the waveform after the strength of FDY is increased, that is to say, the breaking time of POY after twisting and drawing is almost the same as that of FDY after increasing the strength, only the two match intensity reaches its maximum value.

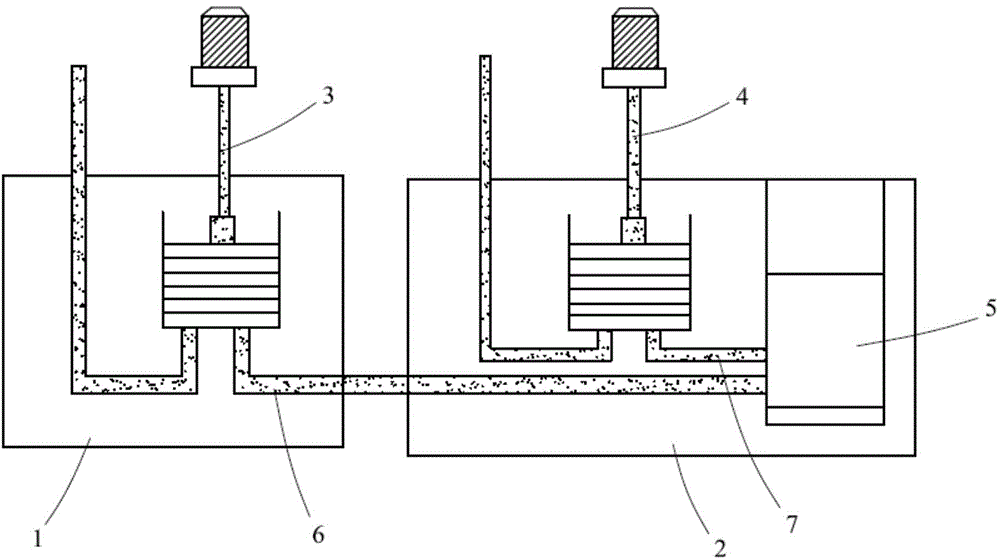

[0021] The technical solutions in the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com