A kind of all-cotton warp thread paint segment-dyed wide-width home textile fabric and its production process

A production process and coating section technology, applied in the field of home textile fabrics, can solve the problems of warp yarn tightness, only suitable for clothing, and yarns are not arranged in parallel, etc., to achieve the effect of eliminating the angle problem, unique style, and fashionable personality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

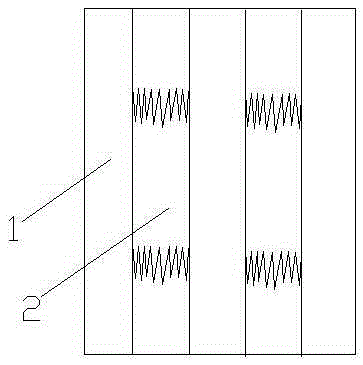

Image

Examples

Embodiment 1

[0021] The production process of a wide-width home textile fabric disclosed by the present invention includes the following steps: dyed yarn warp treatment→segment-dyed yarn warp treatment→warp parallel axis sizing→shaft threading and knotting warp→weft yarn treatment→weaving →Grey fabric inspection and repair→Fabric finishing→Inspection and packaging, of which:

[0022] The process steps of the warp treatment of the colored yarn are: loose tube→tube dyeing→tightening tube→rewinding tube→batch warping;

[0023] The process steps of the warp treatment of the section-dyed yarn are as follows: finishing raw yarn into a shaft→physical pretreatment→painting section dyeing→fixing color→winding into a shaft. , and the ratio of segment dye intervals is the same;

[0024] In the warp thread paralleling and sizing step, the warp beams are first rolled into warp beams through the color warp cycle sequence, and then 18 warp beams are used to guide and install the dyed yarn warps and segm...

Embodiment 2

[0029] The production process of a wide-width home textile fabric disclosed by the present invention includes the following steps: dyed yarn warp treatment→segment-dyed yarn warp treatment→warp parallel axis sizing→shaft threading and knotting warp→weft yarn treatment→weaving →Grey fabric inspection and repair→Fabric finishing→Inspection and packaging, of which:

[0030] The process steps of the warp treatment of the colored yarn are: loose tube→tube dyeing→tightening tube→rewinding tube→batch warping;

[0031] The process steps of the warp treatment of the section-dyed yarn are as follows: finishing raw yarn into a shaft→physical pretreatment→painting section dyeing→fixing color→winding into a shaft. , and the ratio of segment dye intervals is the same;

[0032] In the warp thread paralleling and sizing step, the warp beams are first rolled into warp beams through the color warp cycle sequence, and then 18 warp beams are used to guide and install the dyed yarn warps and segm...

Embodiment 3

[0037] The production process of a wide-width home textile fabric disclosed by the present invention includes the following steps: dyed yarn warp treatment→segment-dyed yarn warp treatment→warp parallel axis sizing→shaft threading and knotting warp→weft yarn treatment→weaving →Grey fabric inspection and repair→Fabric finishing→Inspection and packaging, of which:

[0038] The process steps of the warp processing of the colored yarn are: loose tube→tube dyeing→tightening tube→rewinding tube→batch warping;

[0039]The process steps of the warp treatment of the section-dyed yarn are as follows: finishing raw yarn into a shaft→physical pretreatment→painting section dyeing→fixing color→winding into a shaft. , and the ratio of segment dye intervals is the same;

[0040] In the warp thread paralleling and sizing step, the warp beams are first rolled into warp beams through the color warp cycle sequence, and then 18 warp beams are used to guide and install the dyed yarn warps and segm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com