Polyurethane compression-resistant floor structure and its construction method

A polyurethane and flooring technology, applied in polyurea/polyurethane coatings, coatings, construction, etc., can solve the problems of poor floor compression resistance, heavy floor pressure, equipment cracks, etc., and achieve strong compression resistance, The effect of enhanced ability to withstand ground pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

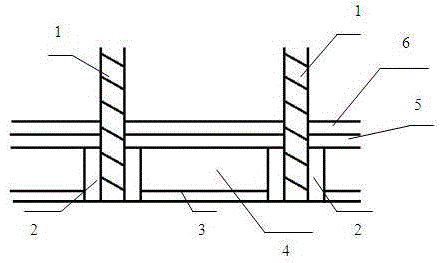

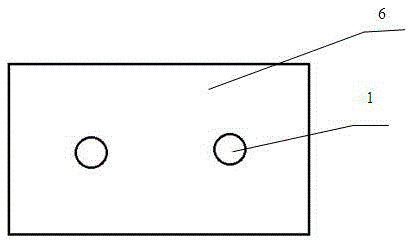

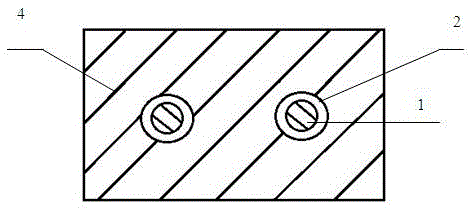

[0025] like figure 1 and figure 2 As shown, this embodiment provides a polyurethane compression-resistant floor structure. An aluminum-plastic board 2 is arranged on the periphery of the track and field equipment 1. A rigid base layer 3 and a gypsum base are laid on the periphery of the aluminum-plastic board 2 from bottom to top. A leveling layer 4 , on which the aluminum-plastic plate 2 and the gypsum-based leveling layer 4 are laid, a polyurethane elastic material middle coating 5 and a water-based polyurethane topcoat 6 .

[0026] Further, the height of the aluminum-plastic plate 2 along the axial direction of the track and field equipment does not exceed the height of the gypsum-based leveling layer 4 along the axial direction of the wall column.

[0027] Because this structure is equipped with an aluminum-plastic plate between the track and field equipment and the leveling layer, on the one hand, it can relieve the weight of the track and field equipment on the floor a...

Embodiment 2

[0029] Polyurethane compression-resistant floor structure, a layer of aluminum-plastic board is arranged around the track and field equipment, and a rigid base layer and a gypsum-based leveling layer are laid on the periphery of the aluminum-plastic board from bottom to top. A middle coat of polyurethane elastic material and a top coat of water-based polyurethane are laid on the top of the layer.

[0030] The rigid base is composed of the following components in parts by weight: 120 parts of cement, 50 parts of graded sand, 25 parts of gravel, and 40 parts of crosslinking agent.

[0031] The coating in the polyurethane elastic material is composed of the following components in parts by weight: 60 parts of elastic glue, 45 parts of waste tire powder, and 10 parts of waste plastic.

[0032] The elastic glue is composed of: polyethylene terephthalate 20wt%, polyether N330 25wt%, 2-methylpentamethylenediamine 7wt%, neopentyl glycol 10wt%, hexamethylene diisocyanate 25wt%, dipheny...

Embodiment 3

[0040] Polyurethane compression-resistant floor structure, a layer of aluminum-plastic board is arranged around the track and field equipment, and a rigid base layer and a gypsum-based leveling layer are laid on the periphery of the aluminum-plastic board from bottom to top. A middle coat of polyurethane elastic material and a top coat of water-based polyurethane are laid on the top of the layer.

[0041] The height of the aluminum-plastic plate along the axial direction of the track and field equipment does not exceed the height of the gypsum-based leveling layer along the axial direction of the track and field equipment.

[0042] As mentioned above, the aluminum-plastic plate is bonded with the rigid base layer and the gypsum-based leveling layer through elastic glue.

[0043] The rigid base layer is composed of the following components in parts by weight: 130 parts of cement, 40 parts of graded sand, 20 parts of gravel, and 35 parts of crosslinking agent.

[0044] The midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com