Energy-dissipation self-adaptive anti-seismic anchor rope structure and implementation method thereof

An anti-seismic anchor cable and self-adaptive technology, applied in infrastructure engineering, construction, sheet pile walls, etc., can solve the problems of the failure of anti-seismic anchorage, reducing the instantaneous impact force of the anchor cable, and producing slippery threads of anti-skid threads of the anti-seismic anchorage. To achieve the effect of reducing the internal force of the earthquake, reducing the loss, and improving the adaptive ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

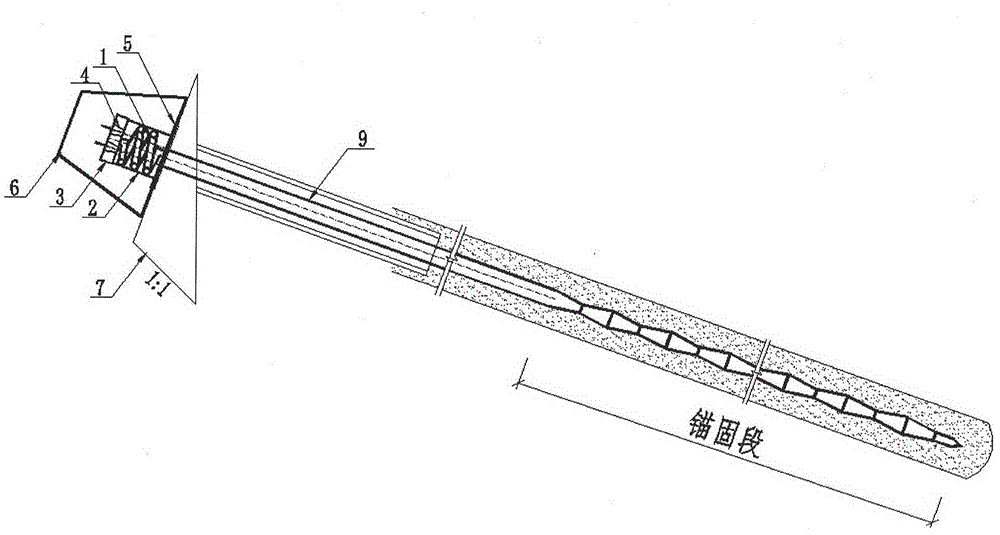

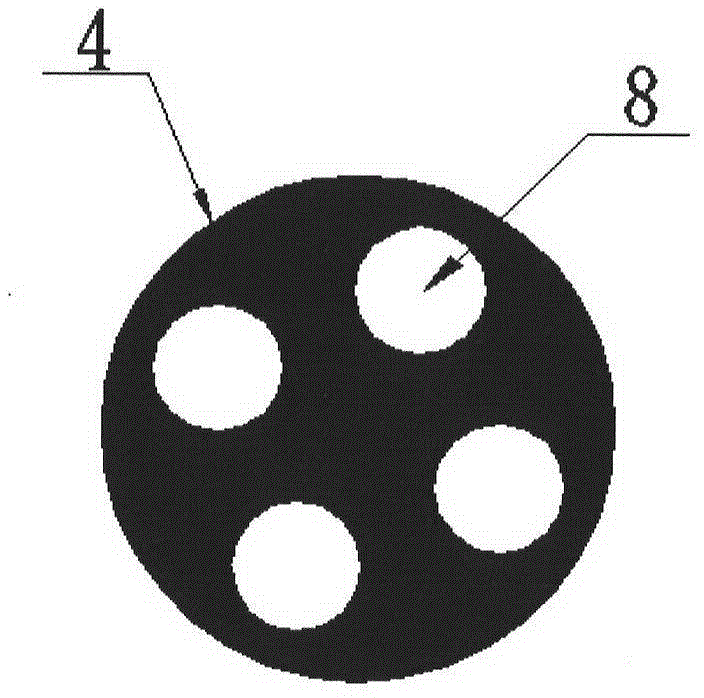

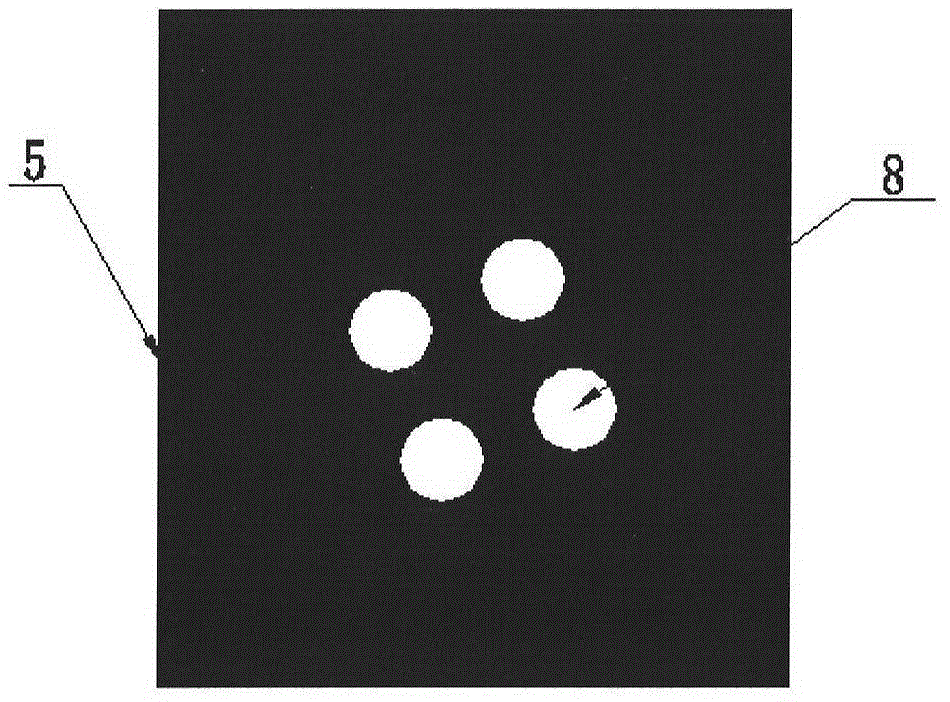

[0018] The core of the present invention is to install a spring device and a sleeve-type metal damper between the bearing plate and the anchor at the end of the prestressed anchor cable. The technical effect to be achieved is: under normal working conditions, the sleeve-type metal damper The spring device can provide initial stiffness to meet the normal function of the structure; under earthquake conditions, the energy dissipation effect of the sleeve-type metal damper can be used to reduce the concentrated internal force generated by the earthquake load on the anchor cable anchorage, especially the anchor cable steel strand The concentrated force between the wire and the anchor cable clip, and the spring device is used to provide the self-restoring force after the earthquake, reducing the loss of prestress. A specific implementation method of an energy-dissipating self-adaptive anti-seismic anchor cable structure is further described below with reference to the accompanying dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com