Sand aerated concrete block operation room and building and constructing method thereof

A technology for concrete blocks and operating rooms, which is used in construction, building components, building structures, etc., can solve problems such as poor thermal insulation performance, heavy wall weight, and complex construction technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

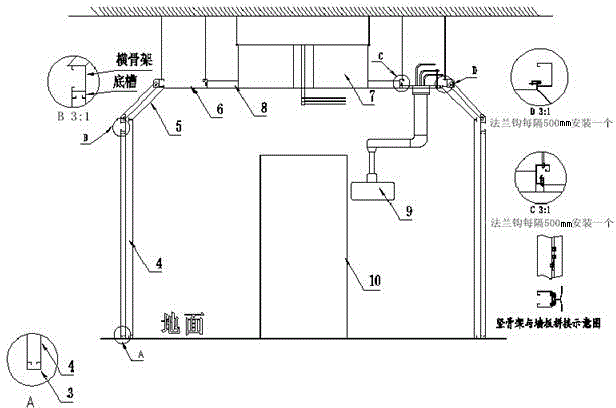

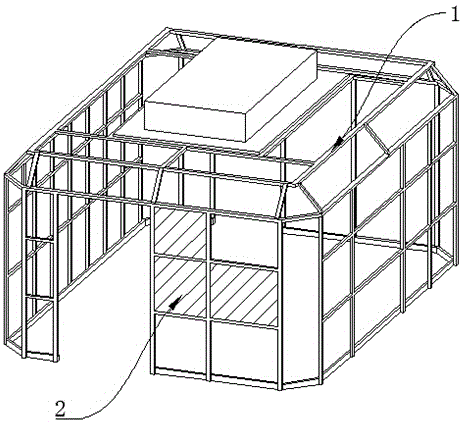

[0029] Such as Figure 1-Figure 2 As shown, a sand aerated concrete block operating room includes an installation keel 1 and a sand aerated concrete block 2 built between the installation keels 1. The installation keel is composed of a steel structure inserted and welded, including an installation bottom Groove 3. Weld the vertical frame 4 on the installation bottom groove. The top of the vertical frame 4 is connected to the oblique frame 5. The oblique frame 5 is connected to the top frame 6. The middle part of the top frame 6 is equipped with a 10,000-level ventilation device 7 to ensure the air quality inside the operating room. There are light strips 8 on the periphery of the 10,000-level ventilation device 7 to provide shadowless lighting for the operation. The upper part of the top frame is also equipped with a pendant 9 extending to the inside of the operating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com