Hydraulic drive oil pumping system for oil well

A liquid flooding and oil pumping technology, which is applied in wellbore/well components, production fluid, earthwork drilling and production, etc. It can solve the problems of unbalanced upstroke and downstroke loads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

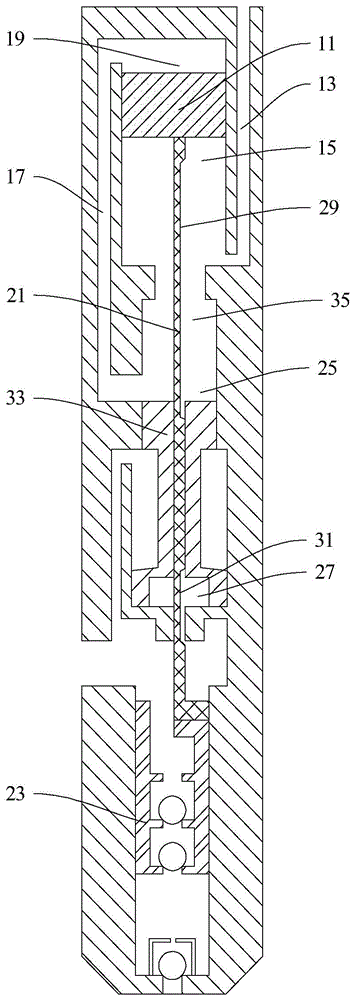

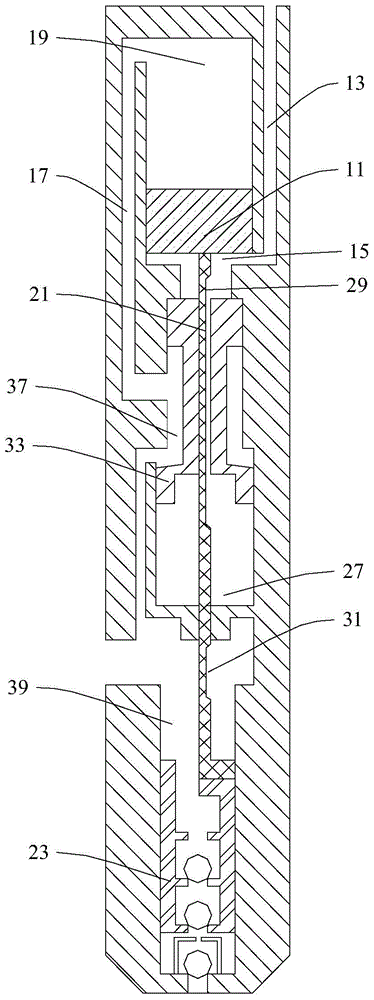

Image

Examples

Embodiment approach

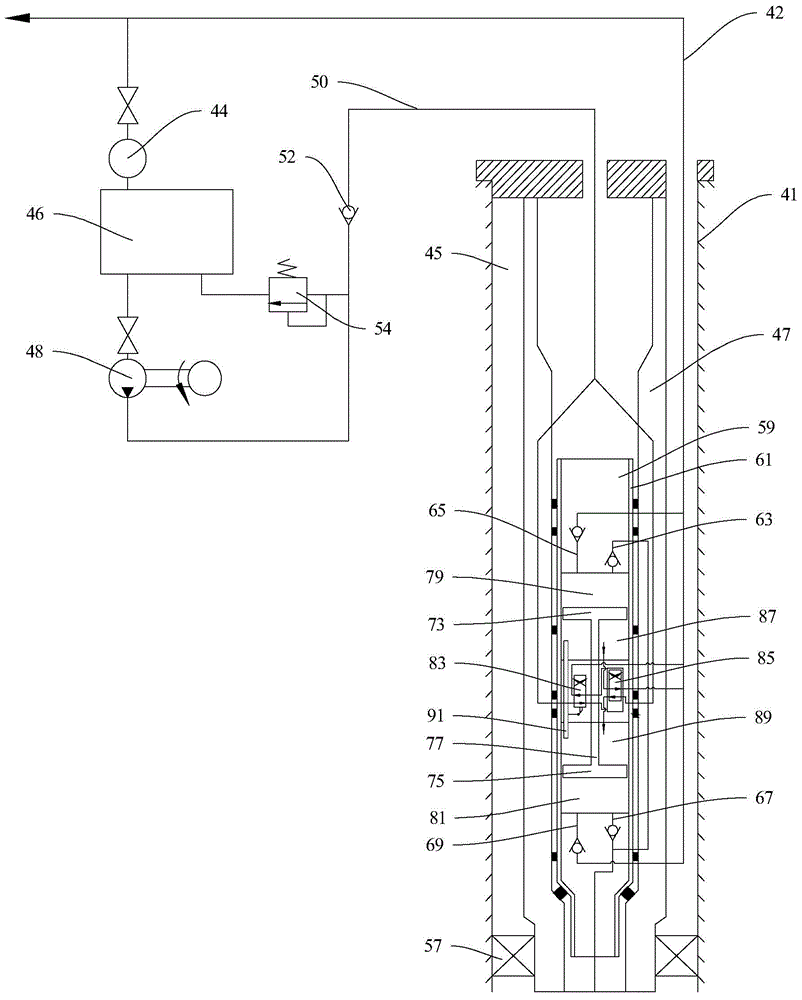

[0059] Another embodiment of the present invention for delivering high-pressure power fluid to the reversing mechanism and outputting formation fluid is:

[0060] Please also see Figure 7 , Figure 10 with Figure 11 .

[0061] A third passage 62 is also arranged in the pipe wall of the first pipe string 47 along its axial direction, and the first port 97, the seventh port 103, the second pipeline 65 and the fourth pipeline 69 are connected with the first The three channels 62 are connected.

[0062] The first pipe string 47 is sleeved with a second pipe string 60, the oil well pump core body 61 can be sealed and sleeved in the second pipe string 60, and the oil well pump core body 61 and the wellhead A second annulus 40 is formed between the first pipe string 47 and the second pipe string 60 , and the second annulus 40 communicates with the third channel 62 .

[0063] The working process of this embodiment is:

[0064] When the first piston 73 pushes the connecting rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com