A Partial Oxidation Steam Injection Forward and Inverse Gas Turbine Combined Cycle

A gas turbine and combined cycle technology, applied in gas turbine installations, combined combustion mitigation, mechanical equipment, etc., can solve problems such as optimizing the pressure ratio drop, achieve self-balancing, improve energy utilization efficiency, and reduce pollutant emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

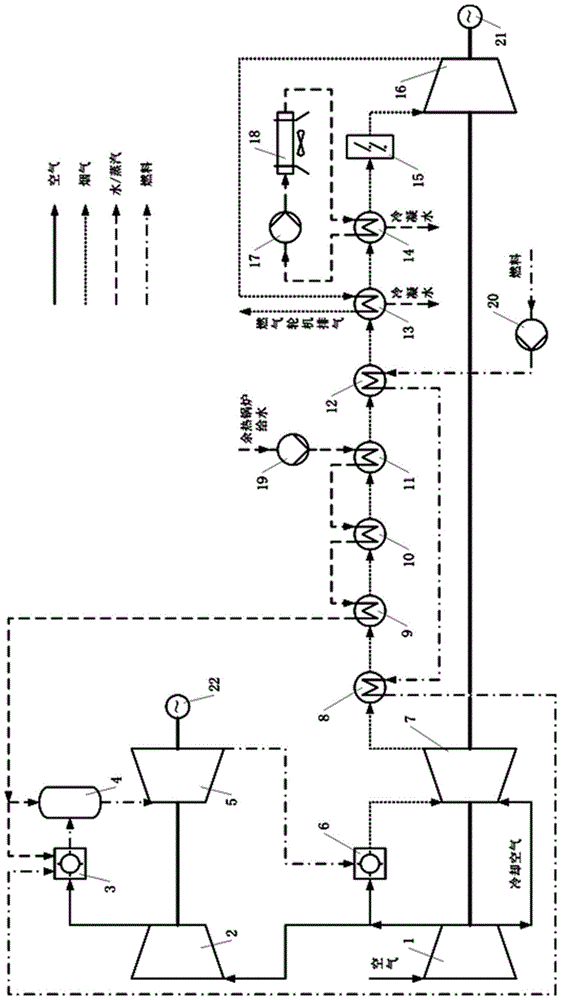

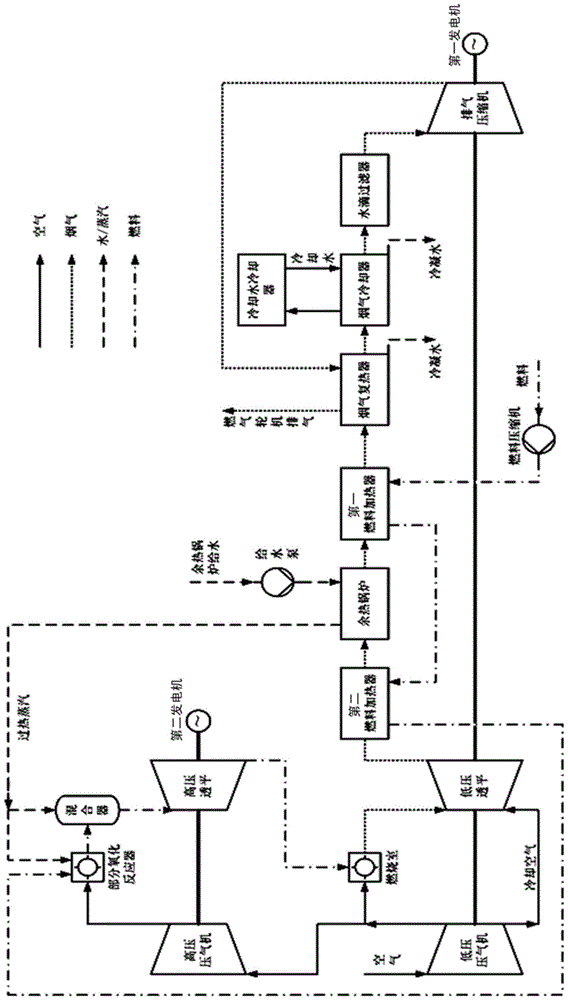

[0050] Please combine figure 1 , the partial oxidation steam injection forward and reverse gas turbine combined cycle of the present invention comprises a low-pressure compressor 1, a high-pressure compressor 2, a partial oxidation reactor 3, a mixer 4, a high-pressure turbine 5, a combustion chamber 6, a low-pressure turbine 7, Second fuel heater 8, superheater 9, evaporator 10, economizer 11, first fuel heater 12, flue gas reheater 13, flue gas cooler 14, water droplet filter 15, exhaust compressor 16 , water pump 17, cooling water cooler 18, water pump 19, fuel compressor 20, first generator 21, second generator 22.

[0051] The specific connection method is:

[0052]The air enters from the air input end of the low-pressure compressor 1; the output end of the low-pressure compressor 1 is connected with the input end of the high-pressure compressor 2, the air input end of the combustion chamber 6, and the cooling air input end of the turbine 7; the high-pressure compressor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com