Gear mechanism based self-rotation blade impeller

A blade impeller and gear mechanism technology, applied to engines, mechanical equipment, wind turbines, etc., can solve the problems of low energy capture efficiency and difficult self-starting, achieve good self-starting performance, reduce headwind resistance, and increase rotational torque.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will now be further described in conjunction with the embodiments and drawings:

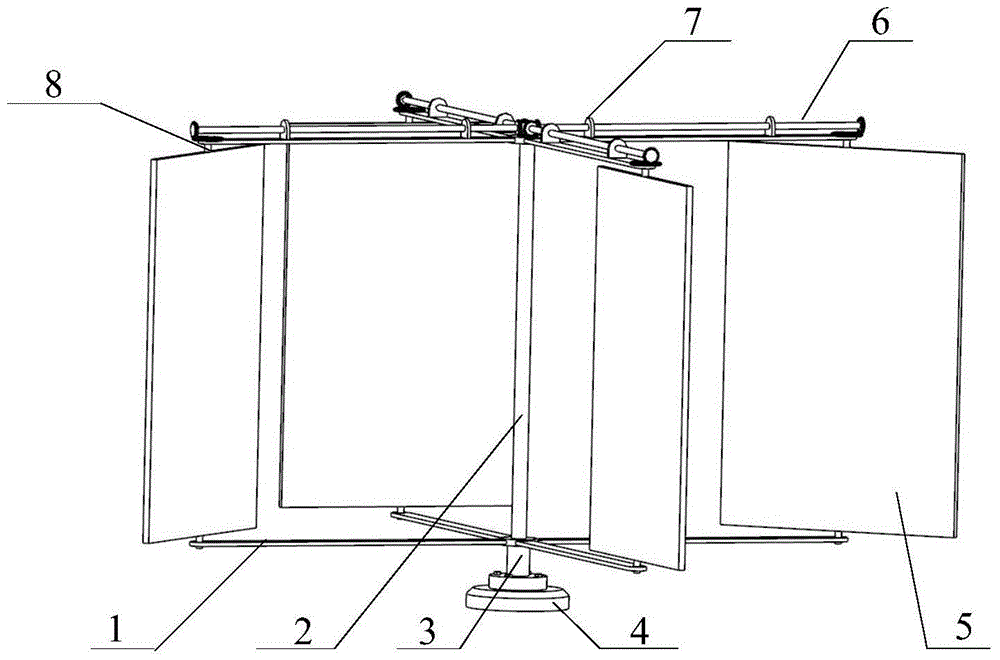

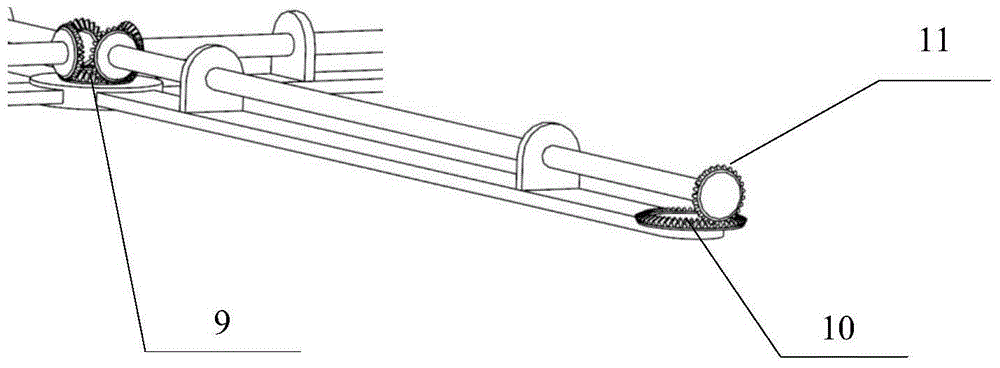

[0031] A self-rotating blade impeller device based on a gear mechanism, which is mainly composed of a rotating cross bracket 1, four blades 5, a central shaft 2, a base 4, a primary bevel gear 9, four secondary bevel gears 10, and eight transmission gears 11 And four drive shafts 6.

[0032] The bottom of the central shaft 2 is fixedly connected with the base 4, and a boss 3 is provided on the upper end of the base 4 to support the cross bracket 1. The length of the central shaft 2 above the boss 3 is slightly longer than the length of the blade 5.

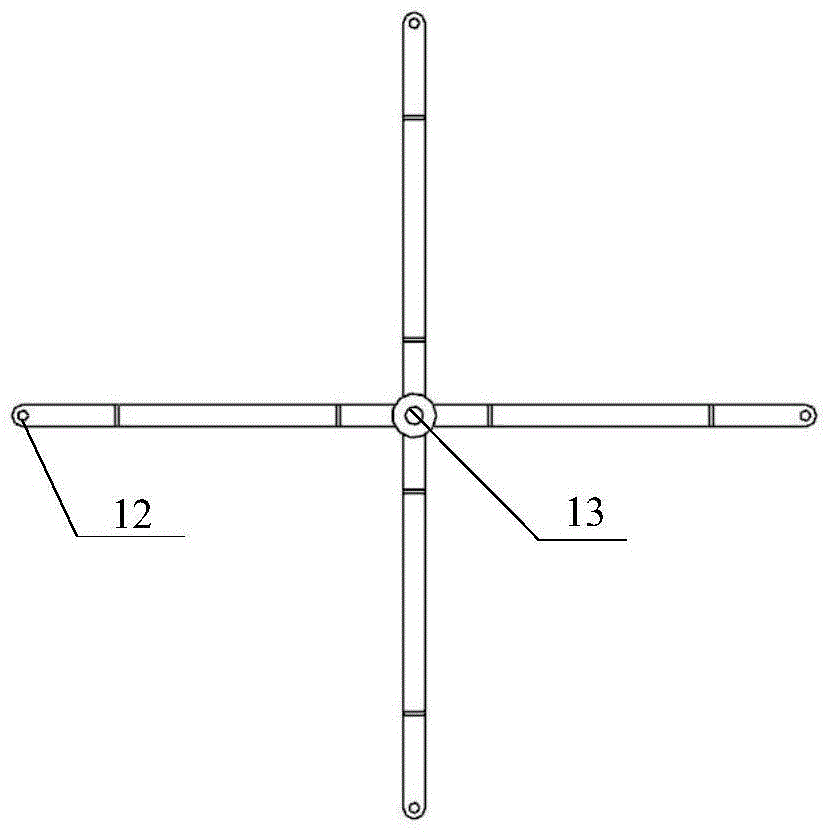

[0033] The rotating cross frame 1 is composed of an upper bracket and a lower bracket. Such as image 3 As shown, the lower bracket has a cross shape as a whole, and a central shaft mounting hole 13 is provided in the center of the cross shape. The hole diameter is between the diameter of the central shaft and the diameter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com