Vertical windmill for fully utilizing bilateral wind energy

A wind energy and windmill technology, applied in the field of fluid kinetic energy receiving devices, can solve problems such as poor utilization and large headwind resistance, and achieve the effects of simplified devices, small headwind resistance, and large windward area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

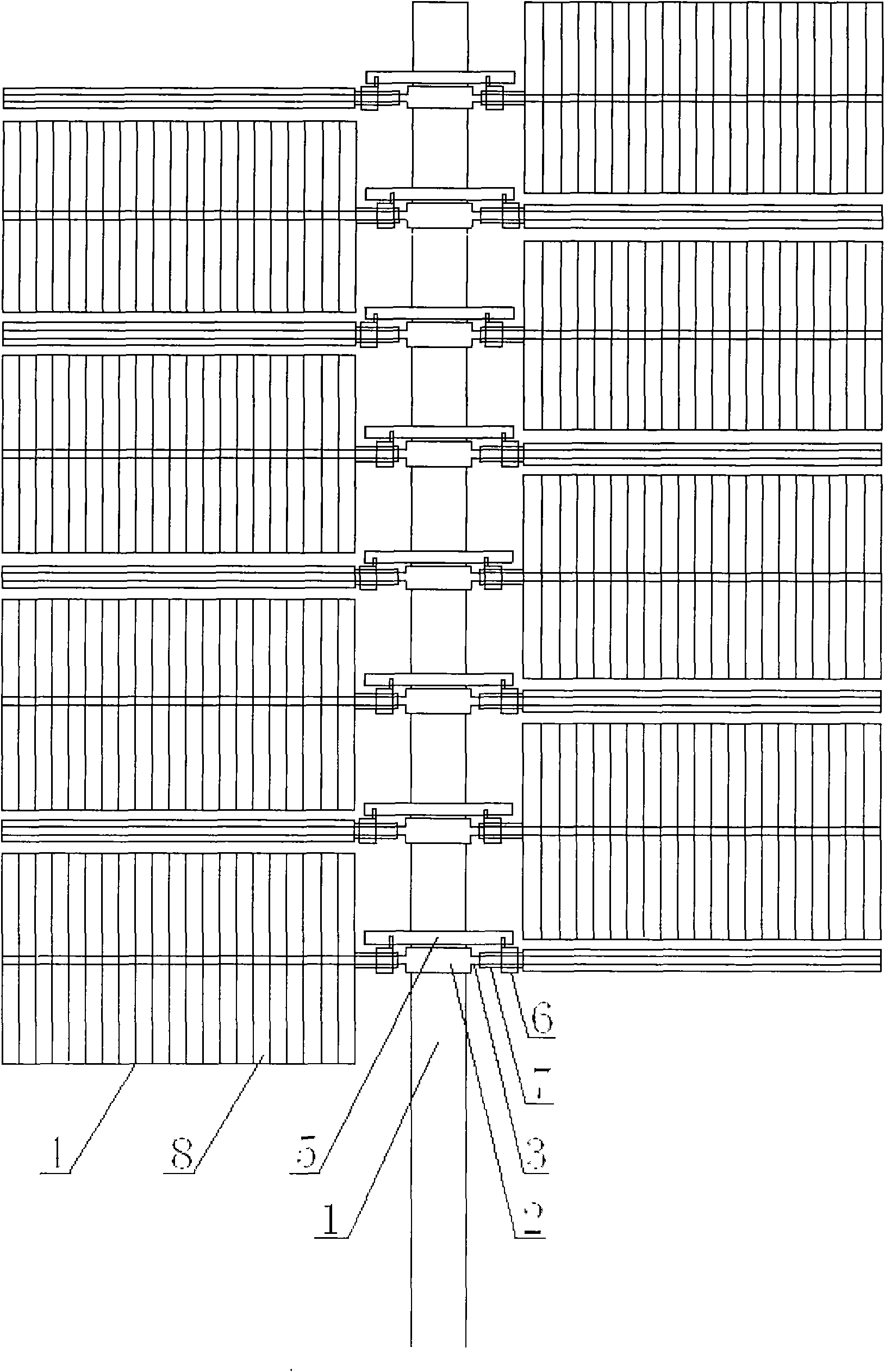

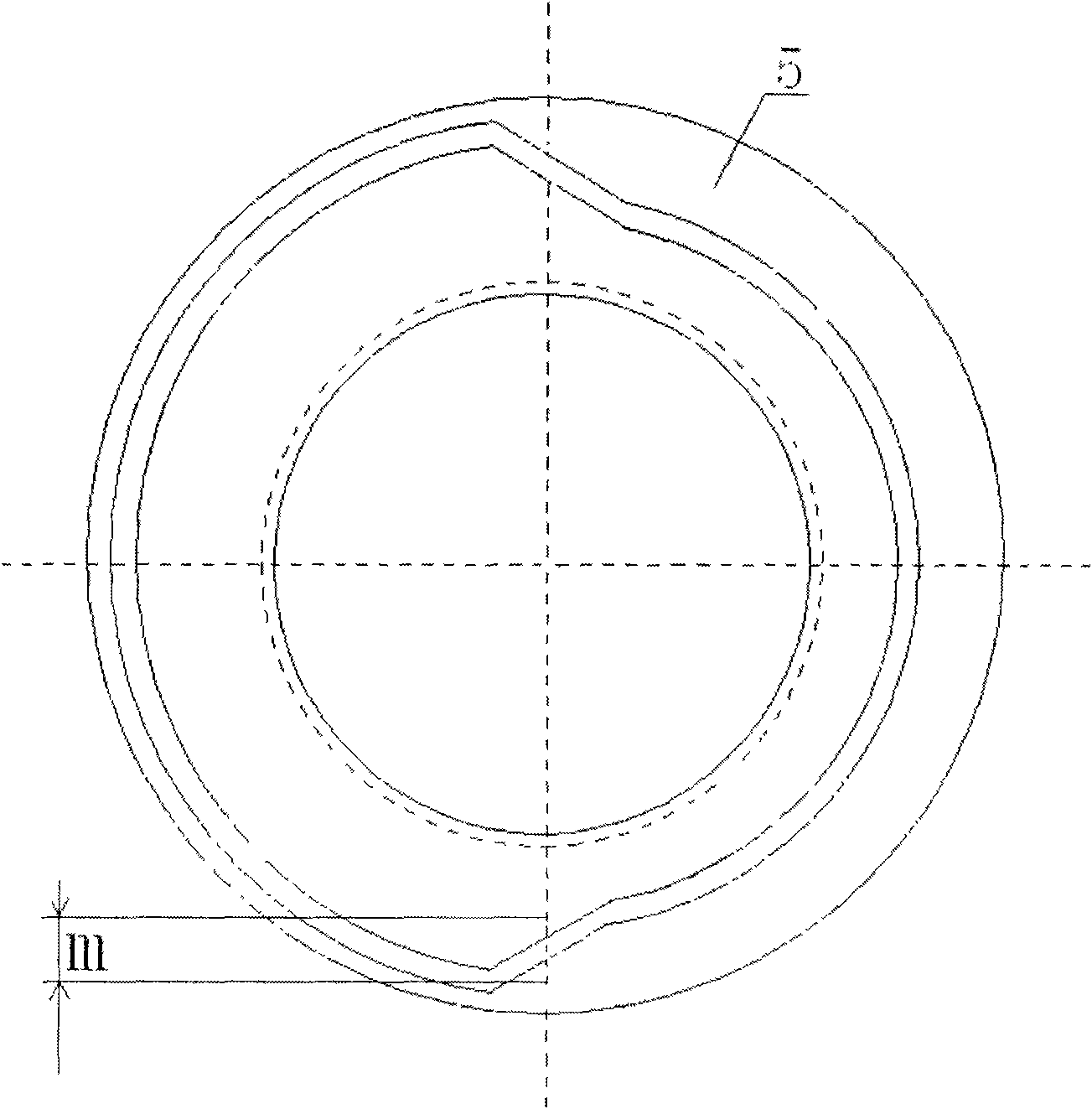

[0015] figure 1 Middle: rotatable large-scale internal tooth gear (2) and rotatable control ring piece (5) are installed layer by layer on the vertical tower (1). Four horizontal force arms (3) are equiangularly connected on the large internal gear (2). Paddle (4), inner-toothed helical wheel (6), and outer-toothed helical wheel (7) are installed on the moment arm (3). Paddle (4) is made up of elastic blade (8) arrangement. The blades are flipped twice a week to maintain the largest area when facing the wind and the least resistance when facing the wind. The rotation directions of the moment arms on the adjacent floors are opposite, so that the wind energy on both sides of the vertical tower can be fully utilized.

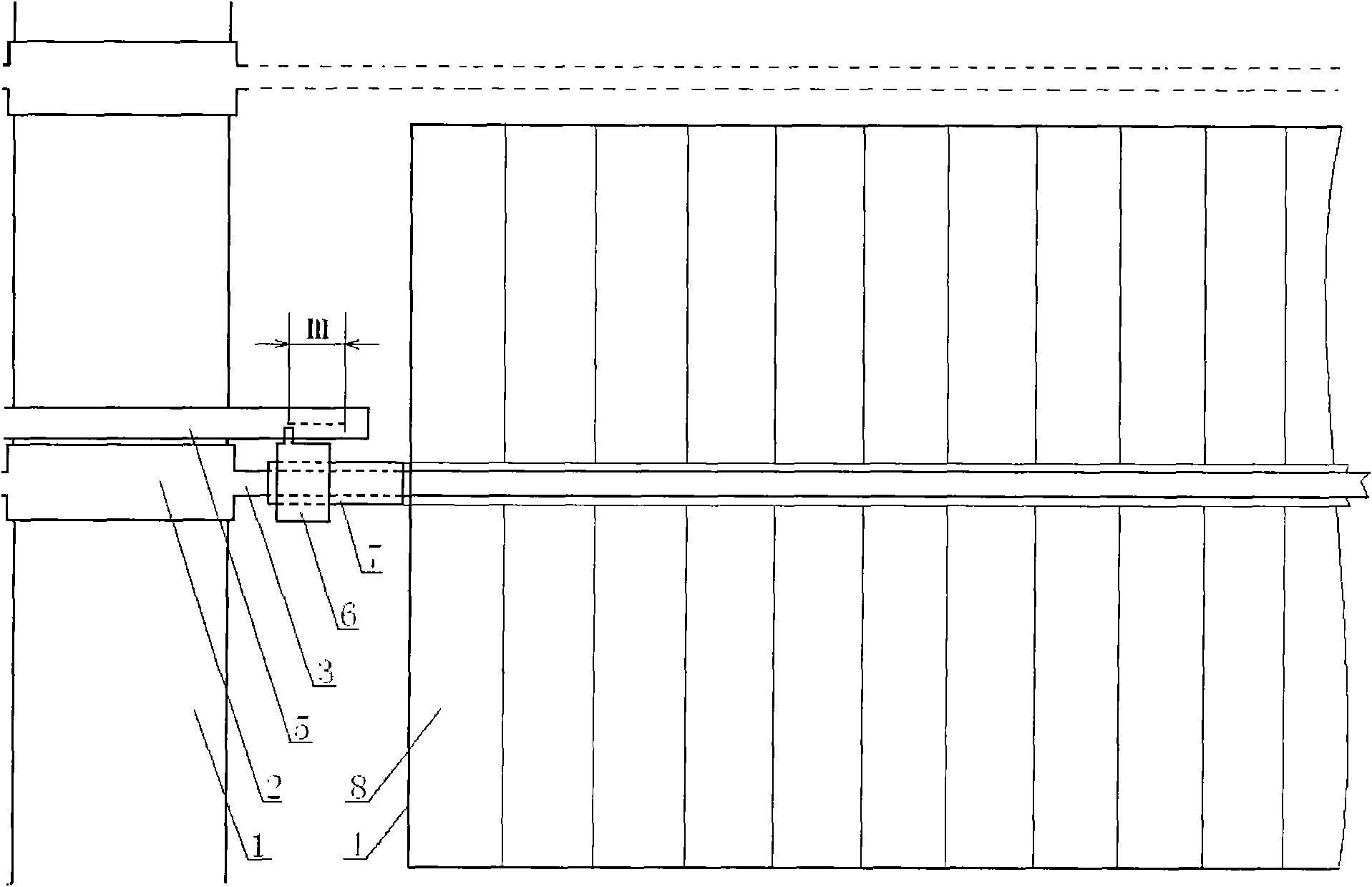

[0016] figure 2 Middle: the paddle (4) (only part is drawn in the figure) is fixedly connected with the external tooth helical wheel (7), and can turn around the moment arm (3), be vertical when facing the wind, and turn to be horizontal when facing the wind. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com