Rising swing blade type vertical-shaft wind generating set

A technology of wind turbines and vertical shafts, which is applied to wind motor combinations, wind engines, and wind engines at right angles to the wind direction, etc. It can solve the problems of difficult use, low service life, and low speed of wind rotors, and achieve strong wind resistance Good, the effect of preventing excessive power and preventing excessive speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

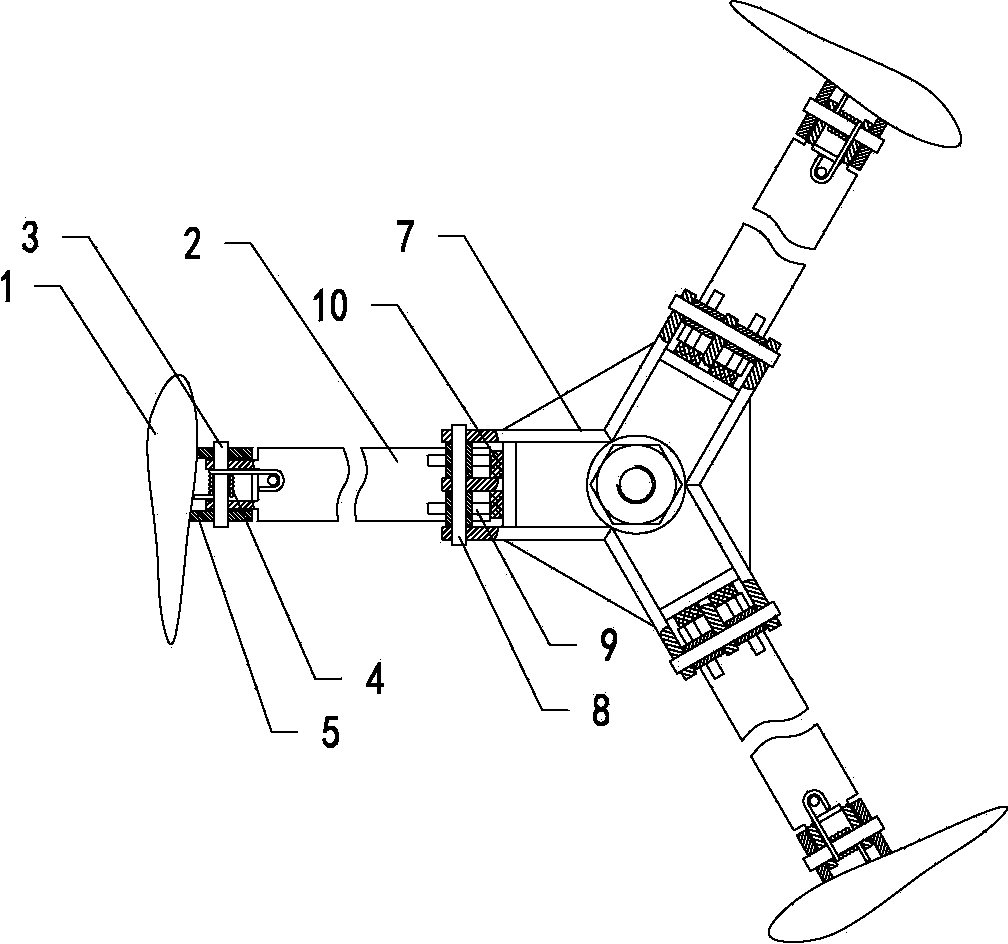

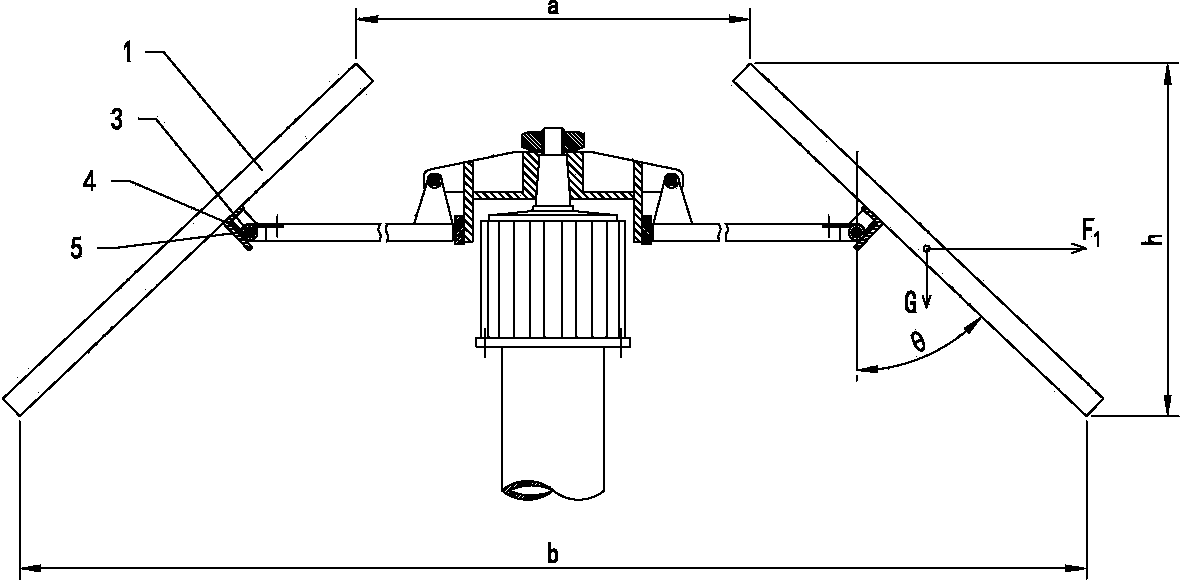

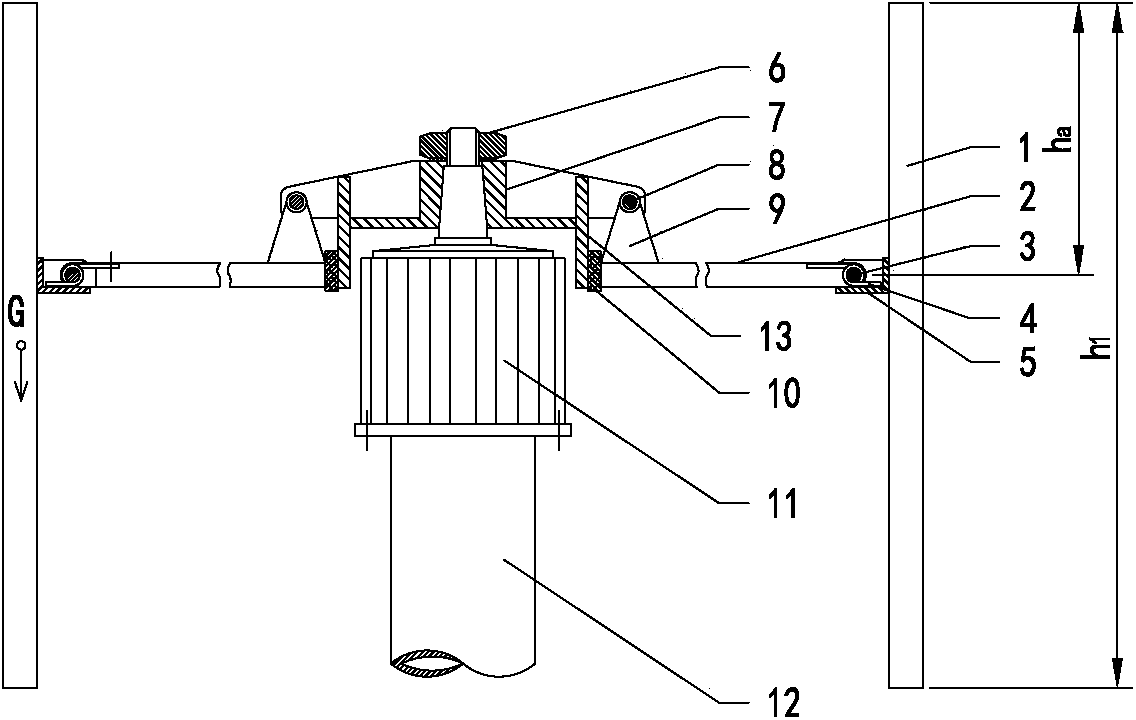

[0044] A wing-swinging-blade vertical-axis wind power generating set of the present invention, such as Figure 1 to Figure 3 As shown, it includes a generator 11 installed on the tower column 12 and a wind wheel installed on the vertical axis of the generator 11. The wind wheel includes a rotating bracket 7 and a plurality of sets of fan blade units. The rotating bracket 7 and the generator 11 The vertical axis is fixedly assembled and connected. Each group of fan blades 1 unit includes a support rod 2, a hinge mechanism and a fan blade 1. One end of the support rod 2 is provided with a hinged seat 9, which is hinged with the rotating bracket 7 through the first pin shaft 8. , the fan blade 1 is hinged to the other end of the strut 2 through a hinge mechanism, and when the wind wheel is stationary, all the struts 2 are at the same level. Wherein, the axial direction of the first pin shaft 8 is perpendicular to the length direction of the corresponding strut 2 , so that the bla...

Embodiment 2

[0066] A wing-swinging-blade vertical-axis wind power generating unit of the present invention is basically the same as Embodiment 2. In this embodiment, the five hinges are fixedly arranged on the groove-shaped hinges of the wind blade 1, and the two side walls A through hole for passing through the second pin shaft 3 is opened symmetrically, and the axis direction of the through hole is perpendicular to the length direction of the fan blade 1 . At the same time, one end of the support rod 2 hinged with the hinge 5 is provided with a hinge joint, and the hinge joint is provided with a through hole for passing through the second pin shaft 3, and the axis direction of the through hole is perpendicular to the length direction of the fan blade 1. And the hinge is located in the groove of the hinge 5, and the second pin 3 passes through the through hole of the hinge 5 and the through hole of the hinge. The second end of the hinge 5 is hinged to the strut 2 through the second pin 3...

Embodiment 3

[0069] A wing-swinging-blade vertical axis wind power generating unit of the present invention is basically the same as Embodiment 2. In this embodiment, the number of blade units is set to two groups, and the included angle between the two groups of blade units is 180°. °, the wind wheel of this structure has few materials, light weight and low cost.

[0070] The main technical solutions of this embodiment are basically the same as those of Embodiment 1 or Embodiment 2, and the features not explained in this embodiment are explained in Embodiment 1 or Embodiment 2, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com