Spring - mass damping device

A vibration damping device and quality technology, applied in the direction of spring/shock absorber, shock absorber, shock absorber, etc., can solve problems such as difficult to observe, and achieve the effect of eliminating rack vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

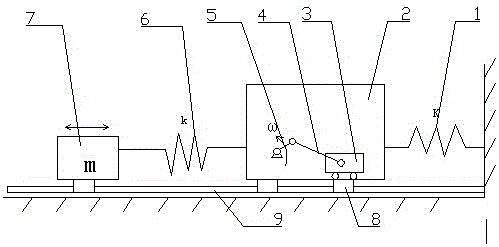

[0010] Such as figure 1 As shown, the same slide rail 9 is provided with a vibration damping mass 7 and a frame 2 sliding along the slide rail, and a second spring 6 is connected between the vibration damping mass 7 and the frame 2; A first spring 1 is connected between the other end of the frame 2 and the fixture. The frame 2 is equipped with a slider crank mechanism, and a bearing 8 cooperating with the slide rail 9 is installed below the frame 2. The slider crank mechanism The sliding block 3 slides on the frame in the same direction as the frame slides along the slide rail.

[0011] The slider crank mechanism is driven by a motor mounted on the frame to realize reciprocating swing.

[0012] figure 1 In the structure shown, the principle of vibration is that the movement of the crank slider causes the center of mass of the frame to shift, causing vibration of the frame, including the first spring 1, the frame 2, the slider 3, the connecting rod 4, and the crank 5. The cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com