Drying device with intelligently-adjusted inlet opening degree

A drying device and inlet technology, which is applied in drying, drying solid materials, lighting and heating equipment, etc., can solve the problems of low efficiency and low intelligence, and achieve good drying effect and fast drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be noted that the board here refers to a board-shaped material, such as board-shaped wood, thermal insulation board, etc.

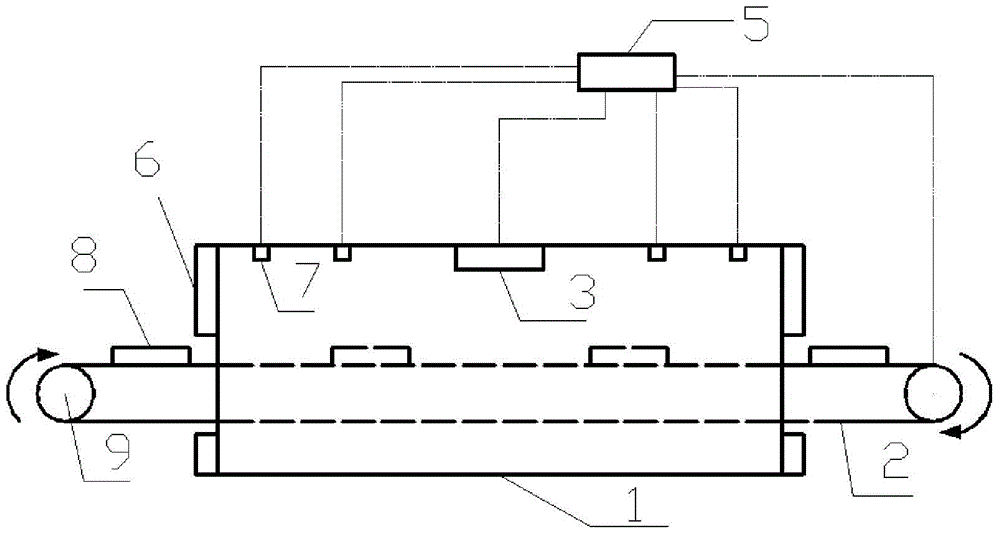

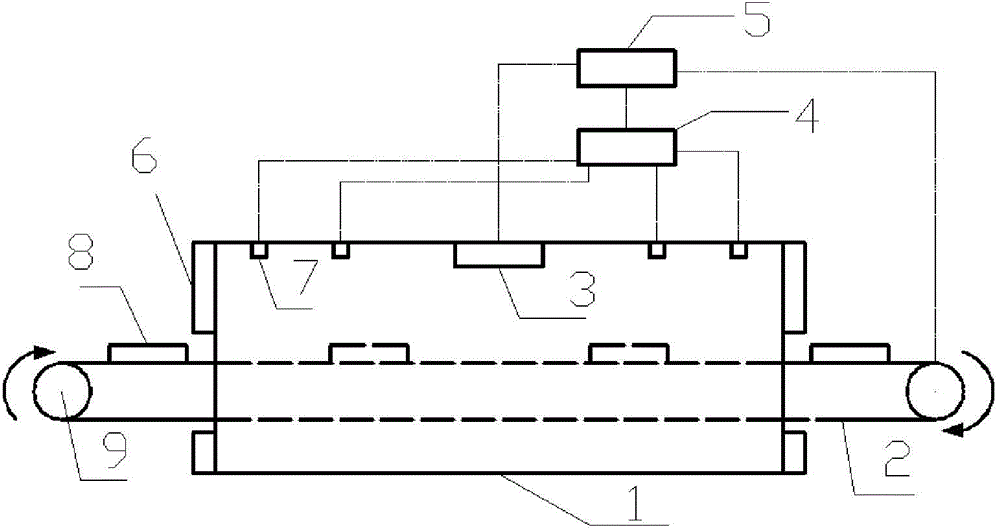

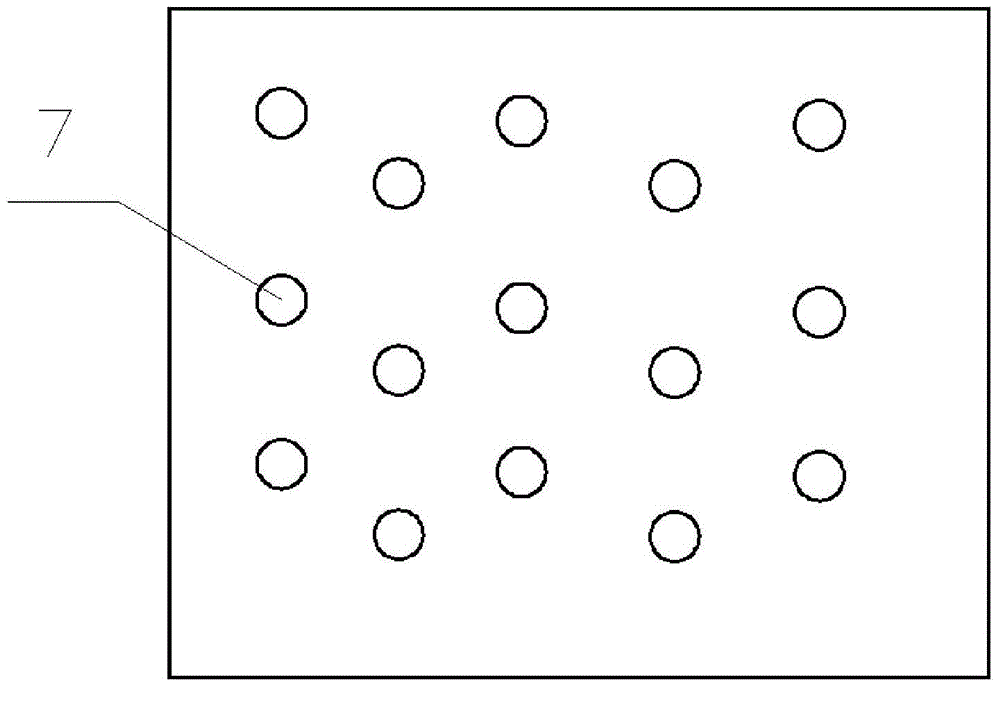

[0024] Such as figure 1 As shown, a drying device for a sheet 8 includes a box body 1, a heating part 3, a temperature sensor 7, a programmable controller 5, and a conveyor belt 2. The conveyor belt 2 passes through the box body 1, the heating part 3 and the temperature sensor 7 is installed in the box, and the heating part 3 and the temperature sensor 7 are connected to the programmable controller 5.

[0025] Preferably, the conveyor belt is provided with a speed control part, and the speed control part is data-connected with the programmable controller 5, and the programmable controller 5 controls the speed of the conveyor belt through the speed control part.

[0026] Preferably, the speed control component includes a speed detection component, which transmits the detected conveyor belt data to a programmable controller, and the programmable c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com