Checkweigher for weighing slide way

A technology of checkweigher and slideway, applied in the field of checkweigher, to achieve the effect of solving the problem of dynamic weighing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

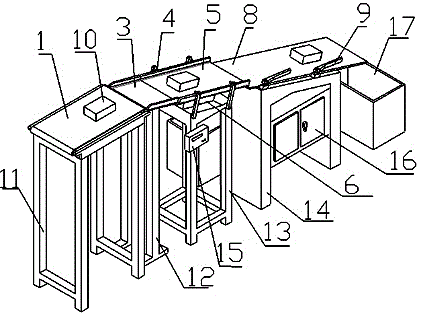

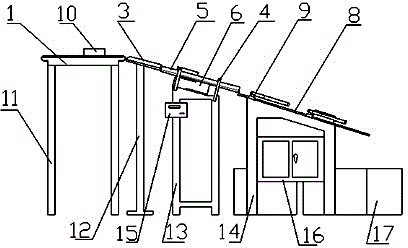

[0039] Such as Figure 1-2 Shown, a kind of checkweigher of slideway weighing, it comprises the 3rd support frame 13 and the 4th support frame 14, is provided with load cell 6 on the 3rd support frame 13, is provided with load cell 6 The weighing chute 5 placed obliquely; the fourth support frame 14 is provided with a rejecting platform and a grading mechanism 9; the rejecting platform is placed below the discharge port of the weighing chute 5; The slideway 5 is rigidly connected and the load cell 6 is designed to carry a force direction perpendicular to the material sliding direction of the weighing slideway 5 . The rear end of the weighing slideway 5 is docked with the front end of the rejecting platform with a gap.

[0040] The weighing slideway 5 is a smooth groove on the contact surface with the material, the angle between the axis of the groove surface and the horizontal plane is A, and the inclined rigid slideway is 0°

Embodiment 2

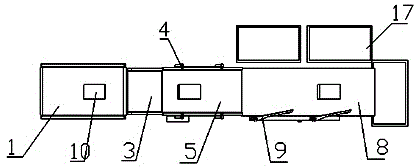

[0065] Example 2: The reject platform is a normal powered belt. Use ordinary power belt instead of the power belt rejecting and classifying device 7 that needs synchronous control, see Figure 4 .

[0066] Such as Figure 4 As shown, the similarities between this embodiment and Embodiment 1 will not be described in detail. The rejecting and grading device 7 is changed to horizontally rejecting the power belt 7, and the drive motor, belt, and drum required by the common technology on the market are adopted, and there is no linear speed synchronous control requirement. The power belt of the electrical control scheme (such as the belt conveyor produced by Shanghai Yingsheng Machinery Co., Ltd.), the total price is 2200 yuan, and the upper plane of the belt is placed 20mm below the weighing slideway 5. All the mechanics, installation and electrical connections are also basically the same, as are the weighing instrument 15 and the electrical control device 16, but the electrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com