A kind of automobile deviation frequency test device and automobile deviation frequency test method

A technology of testing device and testing method, which is applied in the direction of measuring device, vehicle testing, machine/structural component testing, etc., can solve the problems of high test work intensity, low efficiency, and inaccurate real-time measurement, etc. Small, convenience-enhancing, size-reducing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

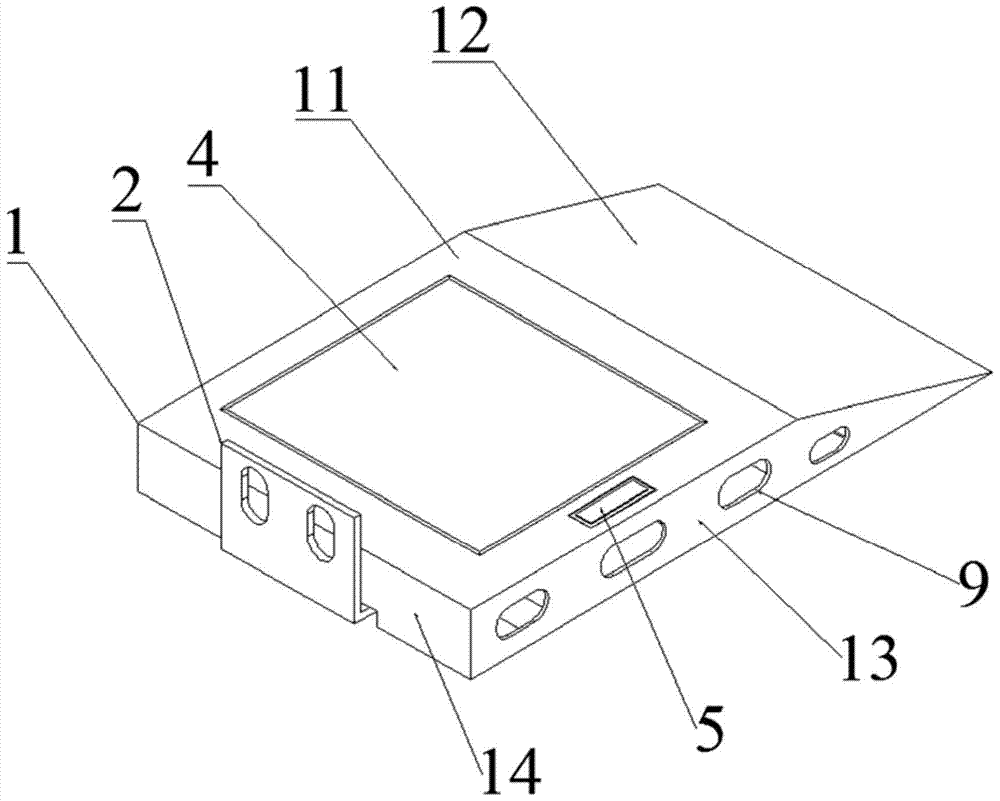

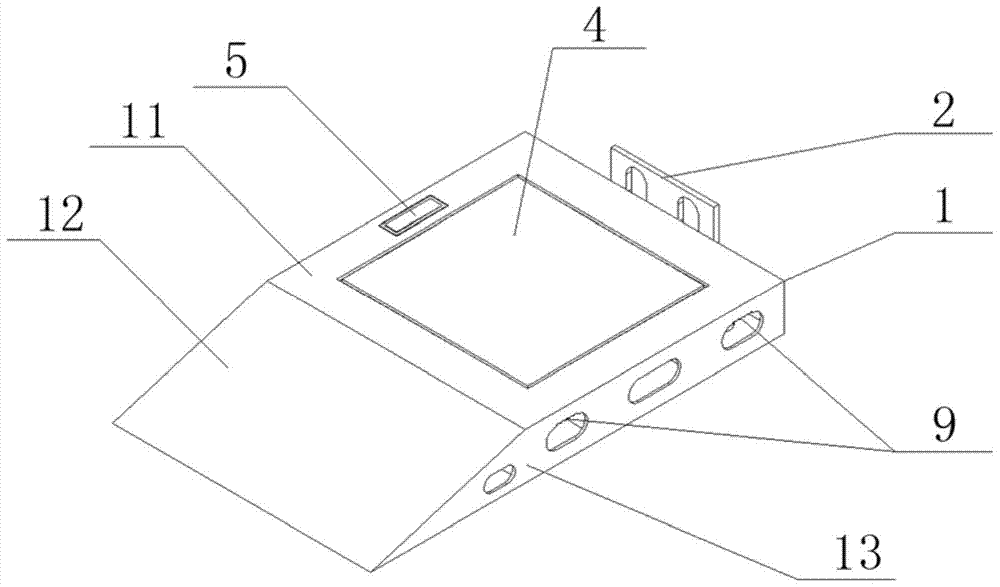

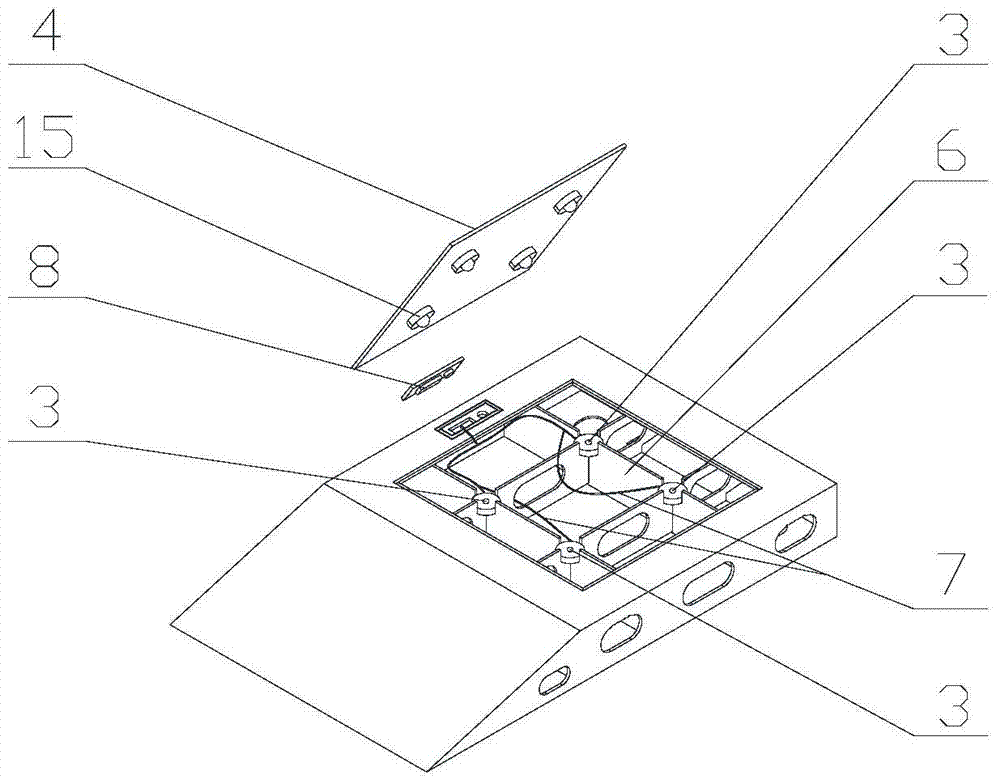

[0034] The automobile bias frequency testing device of the present embodiment, such as figure 1 , 2 , 3, including a base 1, the base 1 is formed by an upper surface and two pairs of oppositely arranged sides, the upper surface of the base 1 is a test table 11, and the test area of the test table 11 is only for waiting Test the single wheel of the car to drive in; the test area is a groove arranged on the test table 11, and the load-bearing plate 4 for carrying the weight of the car to be tested is horizontally arranged in the groove, and the upper surface of the load-bearing plate 4 and the groove The notch is flush; the pressure sensor 3 for collecting the pressure signal of the load plate is arranged between the load plate 4 and the bottom of the groove; one side of the base 1 is used to drive a single wheel of the car to be tested on the load plate Slope surface 12, a side opposite to the slope surface 12 on the base 1 is a vertical surface 14 perpendicular to the test ...

Embodiment 2

[0040] The automobile bias frequency testing method of this embodiment is carried out on the flat ground of the stowage area, and specifically includes the following steps:

[0041] 1) Under the no-load state (only the driver), an acceleration sensor is arranged at the body of the car to be tested and the wheels, and the acceleration sensor is connected to the data acquisition device and the data processor of the peripherals;

[0042] 2) Place the vehicle to be tested on the flat ground in the loading area, and place a vehicle deviation frequency test device in front of each wheel of the vehicle to be tested (a total of four vehicle deviation frequency test devices are required for the vehicle deviation test process) , so that the slope surface is close to the bottom in front of the wheel; at the same time, install the limit baffle on the vertical surface;

[0043] Make each wheel of the car to be tested drive into the test area along the slope of the corresponding car deviati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com