Novel on-line RI detection chromatography and ultrafiltration system

A detection layer and a new type of technology, applied in the field of RI online detection, can solve the problems of inconvenient disassembly of the flow cell, inaccurate flow rate, flat head phenomenon, etc., and achieve stable and controllable results, accurate flow rate, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

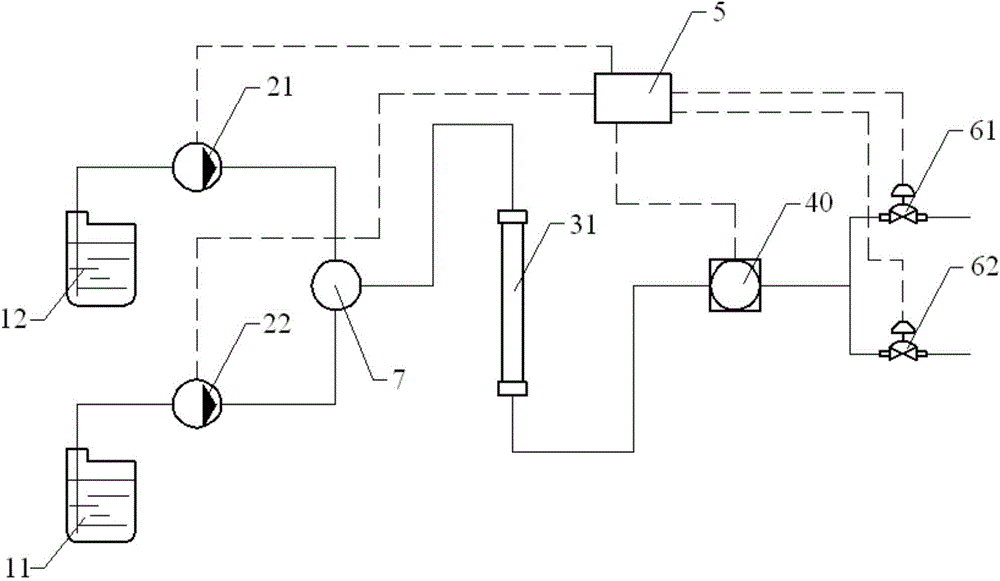

[0022] Such as figure 1 and Figure 5 As shown, a novel RI online detection chromatography system includes a first mobile phase liquid storage tank 11, a second mobile phase liquid storage tank 12, a first pump 21, a second pump 22, a chromatographic column 31, a new RI Online detector 40 and controller 5; the first mobile phase liquid storage tank 11 is connected to the inlet end of the first pump 21; the second mobile phase liquid storage tank 12 is connected to the inlet end of the second pump 22 The outlet port of the first pump 21 and the outlet port of the second pump 22 are connected to the inlet port of the chromatographic column 31 after being connected in parallel through the pipeline; the outlet port of the chromatographic column 31 is connected to the novel RI online detector 40 The signal output end of the novel RI online detector 40 is connected to the signal input end of the controller 5; the signal output end of the controller 5 is respectively connected to th...

Embodiment 2

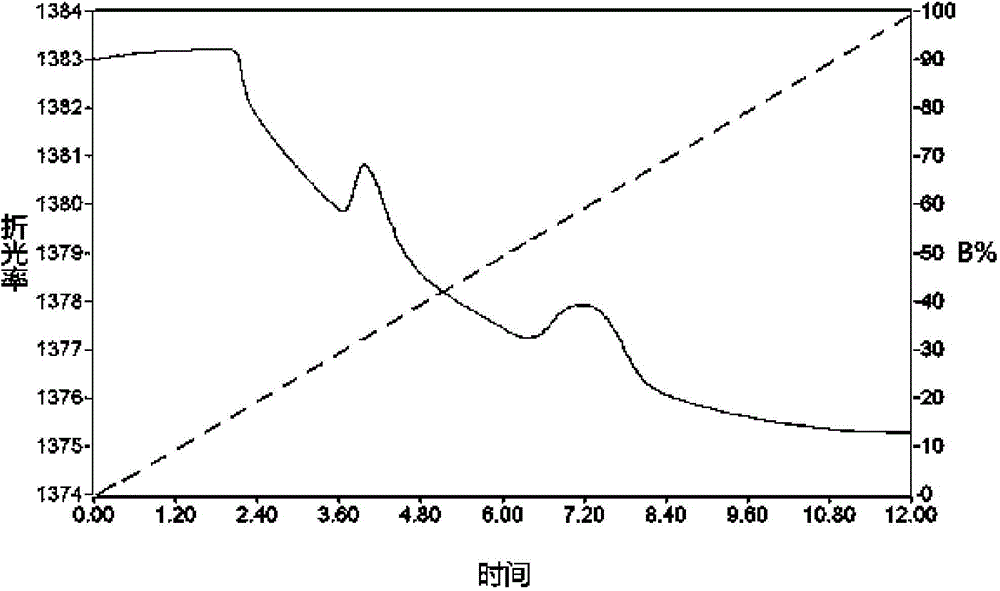

[0028]Adopt a kind of novel RI online detection chromatography system of embodiment one to carry out detection experiment: in the first mobile phase liquid storage tank 11, be pure water, the second mobile phase liquid storage tank 12 is the NaCl solution of 1mol / L, to no ultraviolet The absorbed polysaccharide sample needs to be separated in the chromatographic column 31, and the absorption peak of the sample is detected with the novel RI on-line detector 40, and the difference between the elution and on-line detection process and the embodiment one is: one, in the controller Set the ratio and time of the first pump 21 and the second pump 22 in 5, wherein, the first ratio: the ratio of the first pump 21 is 100%, the ratio of the second pump 22 is 0%; the second ratio : the proportion of the first pump 21 is 90%, the proportion of the second pump 22 is 10%; the third proportion: the proportion of the first pump 21 is 80%, the proportion of the second pump 22 is 20%; the fourth ...

Embodiment 3

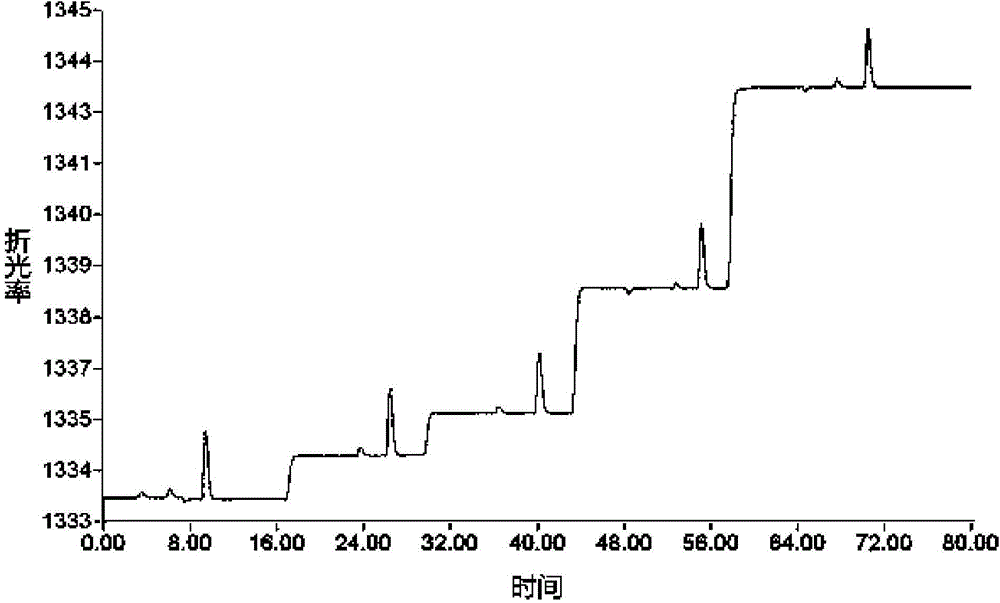

[0031] Such as Figure 4 and Figure 5 As shown, a novel RI online detection ultrafiltration system includes a liquid storage tank 10, a membrane bag input pump 20, a membrane bag 32, a first novel RI online detector 41, a second novel RI online detector 42 and a controller 5; the liquid storage tank 10 is connected to the inlet end of the membrane bag input pump 20; the outlet end of the membrane bag input pump 20 is connected to the inlet end of the membrane bag 32; the return output port of the membrane bag 32 Connected with the first novel RI on-line detector 41; the first novel RI on-line detector 41 is connected to the liquid storage tank 10; the filter end of the membrane bag 32 is connected to the second novel RI on-line detector 42; The signal output end of the first novel RI online detector 41 and the signal output end of the second novel RI online detector 42 are respectively connected with the signal input end signal of the controller 5; the signal output end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com