Circuit board profile process edge milling judgment method

A process edge and circuit board technology, applied in the field of judging the shape of the circuit board and milling into the process edge, can solve the problems of inability to ensure the physical object, slow process edge design, customer complaints, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is further described below in conjunction with specific embodiment:

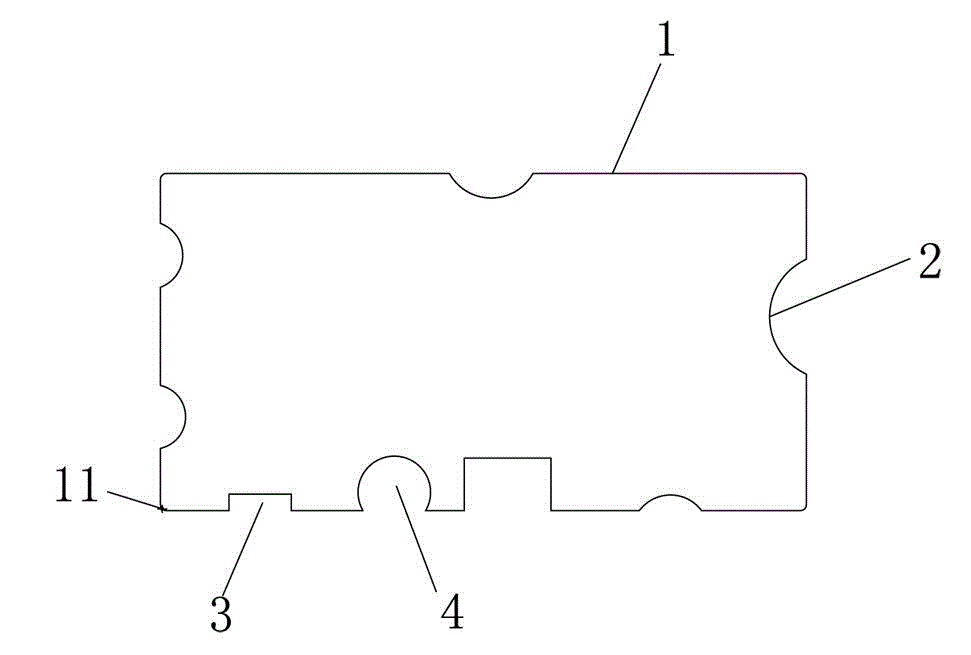

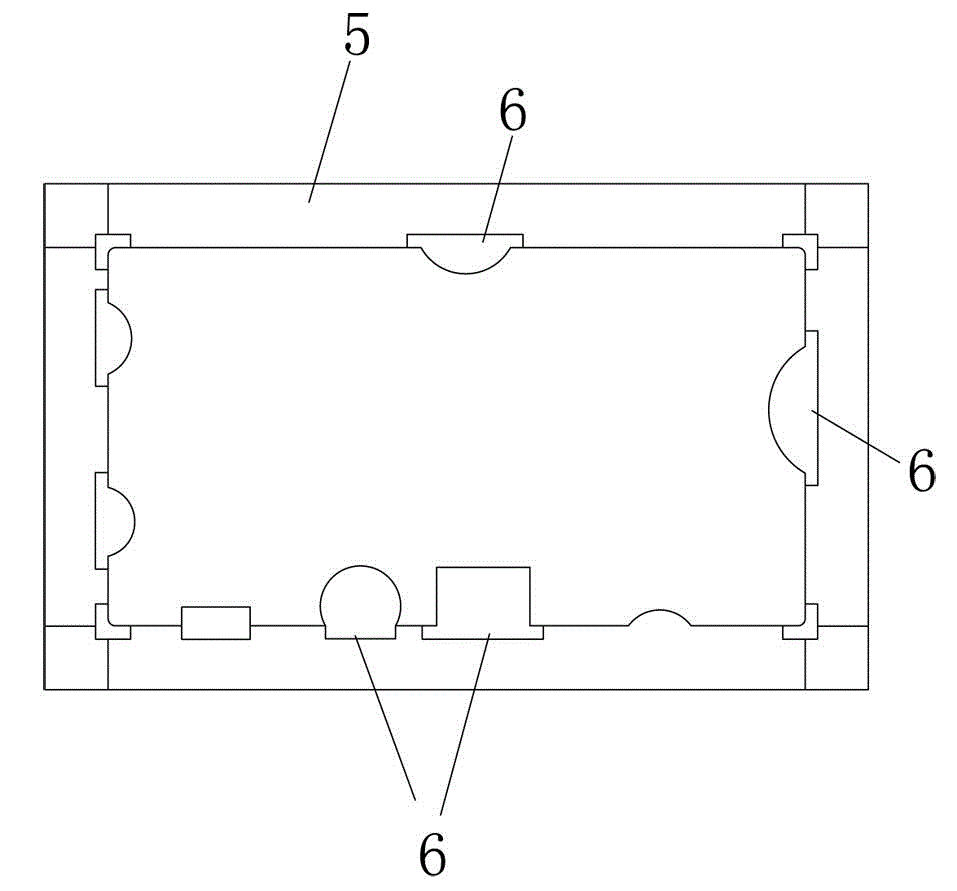

[0024] A method for judging the milling process edge of the circuit board shape, comprising the following steps:

[0025] The first step is to set a zero point and establish a rectangular coordinate system before the graphic design of the shape to ensure that the border lines of the shape are all horizontal or vertical;

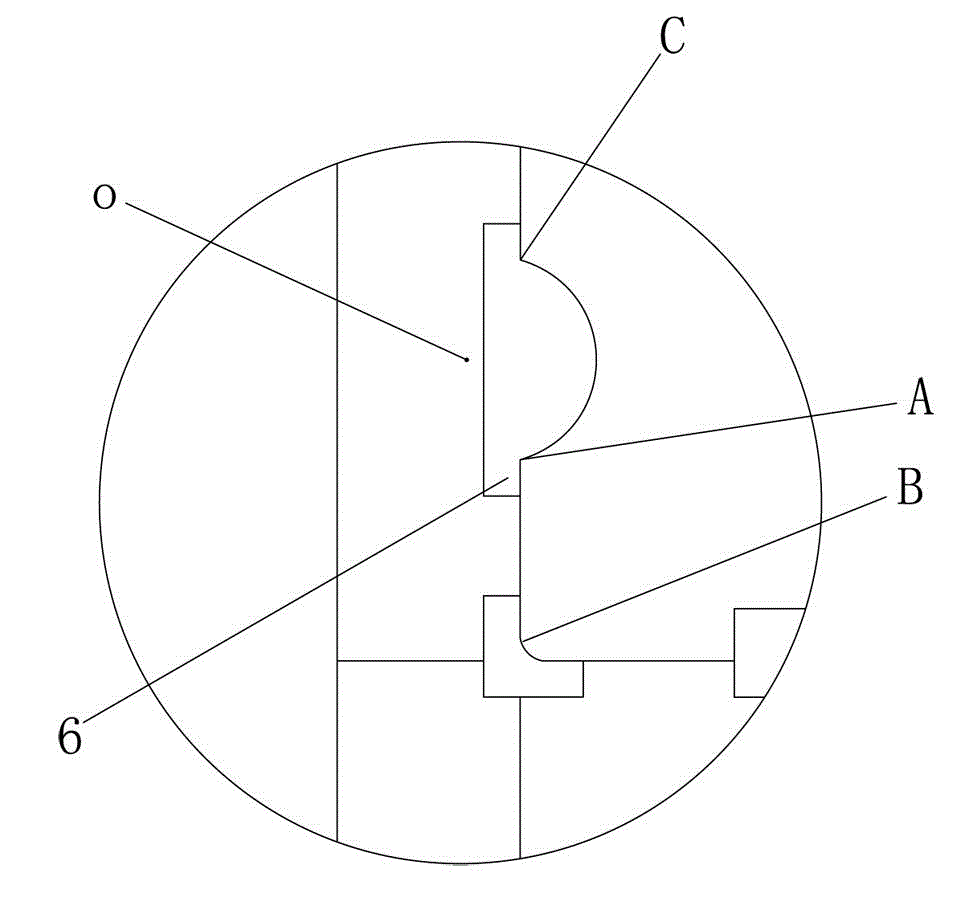

[0026] In the second step, the starting and ending points x and y coordinates of the outline border line are stored as the first level of the hash table, and the starting and ending points of each line segment saved in the first level hash table are used as the center to find out the setting The x and y coordinates of the start and end points of other line segments that meet it within the specified tolerance range, and create a multi-level hash table to save the outline drawing designed by the customer. If it is an arc, save the coordinates of the center of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com