LED display module and manufacturing method thereof

A display module, PCB board technology, applied in lighting and heating equipment, lighting devices, light sources, etc., can solve problems such as cost increase, use environment coordination, large space, etc., to improve transparency, reduce light occlusion, and improve pixel performance. The effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

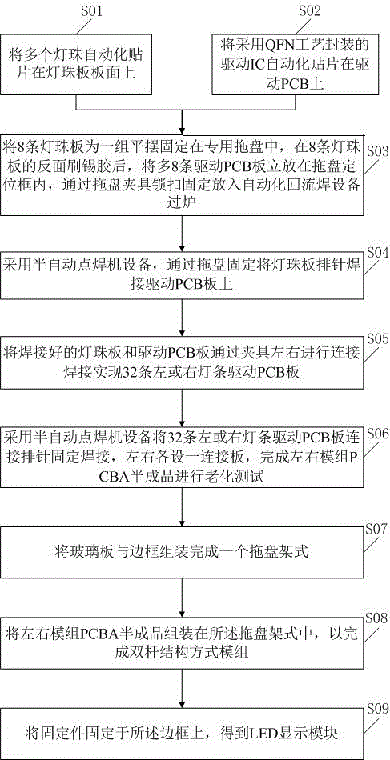

[0049] Correspondingly, an embodiment of the present invention provides a method for manufacturing an LED display module. The schematic flow chart of the method is shown in Figure 13 As shown, the method includes the following steps:

[0050] S01. Automatically patch multiple lamp beads on the surface of the lamp bead board;

[0051] S02. Automatically place the drive IC packaged in the QFN (Quad Flat No-lead Package) process on the drive PCB;

[0052] S03. Fix the 8 lamp bead boards as a group and fix them on the special tray. After brushing tin glue on the reverse side of the 8 lamp bead boards, place the 8 more drive PCB boards in the positioning frame of the tray. The tray fixture lock is fixed and put into the automatic reflow soldering equipment for furnace;

[0053] S04. Adopt semi-automatic spot welding machine equipment, fix the lamp bead board pins and drive the PCB board by fixing the tray;

[0054] S05. Connect and weld the welded lamp bead board and the drivin...

Embodiment 1

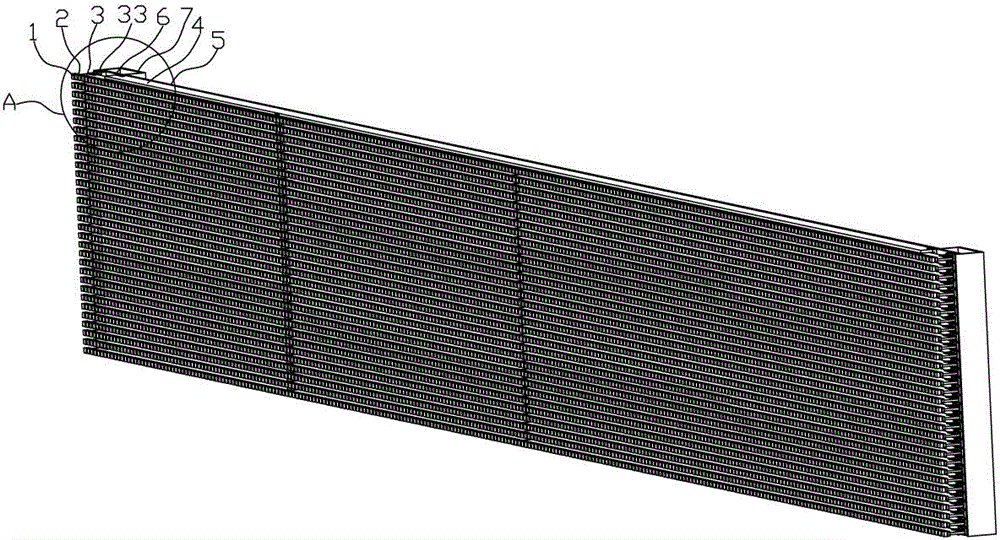

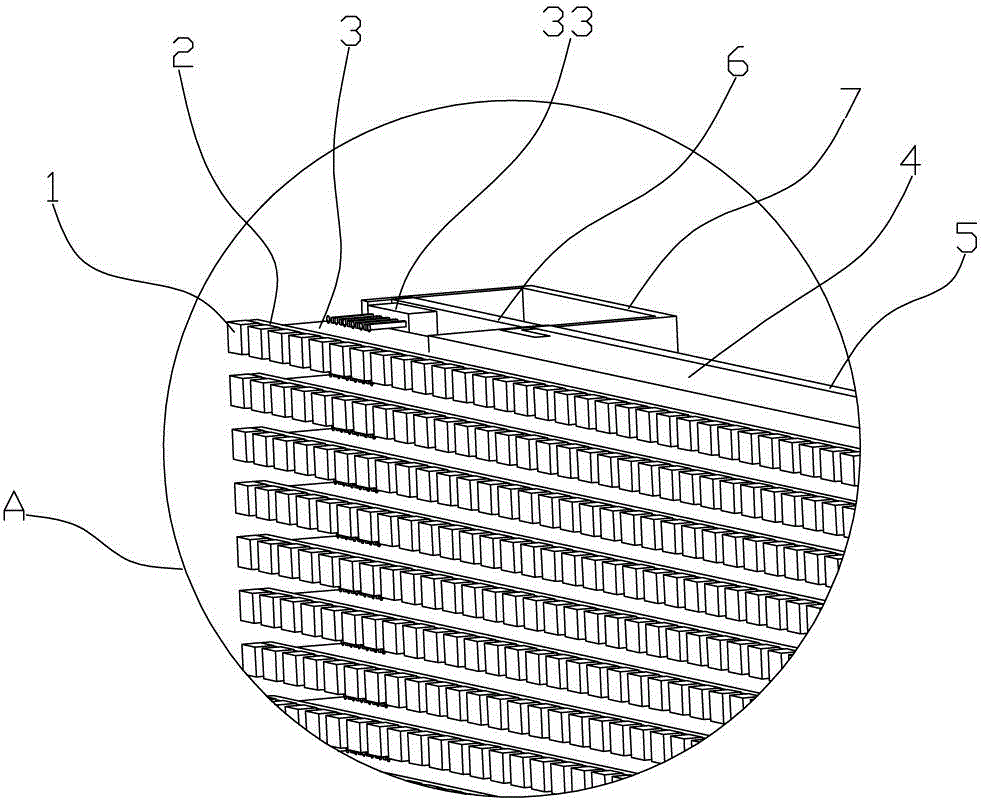

[0066] The LED display module of this embodiment, such as figure 1 , figure 2 and image 3 As shown, it includes a plurality of lamp beads 1, a linearly arranged lamp bead board 2, a linearly arranged drive PCB board 3, a frame body 4, a transparent glass plate 5, a connecting plate 6 and a fixing member 7, and a plurality of lamp beads 1 are fixed on The surface of the lamp bead board 2 is electrically connected to the lamp bead board 2. The lamp bead board 2 is fixed on the driving PCB board 3 and electrically connected to the driving PCB board 3. The board surface of the lamp bead board 2 is perpendicular to the board of the driving PCB board 3 On the surface, the drive PCB board 3 is arranged in the frame body 4, the frame body 4 is fixed on the glass plate 5, the drive PCB board 3 is fixed on the connecting plate 6, the board surface of the drive PCB board 3 is perpendicular to the board surface of the glass plate 5, and the fixing member 7 is fixed on the frame body 4...

Embodiment 2

[0079] The LED display module of this embodiment, such as figure 1 , figure 2 and image 3 As shown, it includes lamp bead 1, linearly arranged lamp bead board 2, linearly arranged drive PCB board 3, frame body 4, transparent glass plate 5, connecting plate 6 and fixing piece 7, and lamp bead 1 is fixed on lamp bead board 2 The board surface is electrically connected to the lamp bead board 2, the lamp bead board 2 is fixed on the driving PCB board 3 and electrically connected to the driving PCB board 3, the board surface of the lamp bead board 2 is perpendicular to the board surface of the driving PCB board 3, and the driving PCB The board 3 is set in the frame body 4, the frame body 4 is fixed on the glass plate 5, the driving PCB board 3 is fixed on the connecting plate 6, the board surface of the driving PCB board 3 is perpendicular to the glass board 5 board surface, and the fixing member 7 is fixed on the frame On the body 4, the frame 4 includes a first sub-frame 41 l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com