Roller feed type humidifier for motor stator insulation paper

A motor stator and humidification device technology, applied in the direction of laying solid insulation, etc., can solve the problems of excessive labor output, uneven humidity of insulating paper, and uneven humidification degree of the humidifying surface, so as to speed up space movement, reduce labor output, and enhance humidification effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

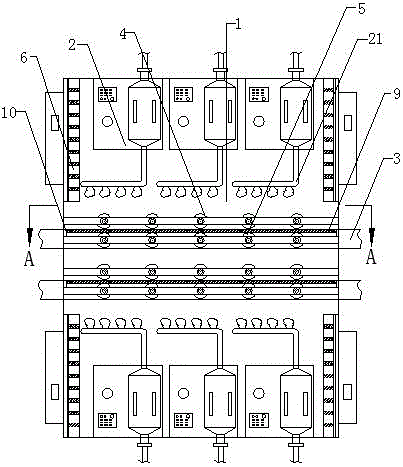

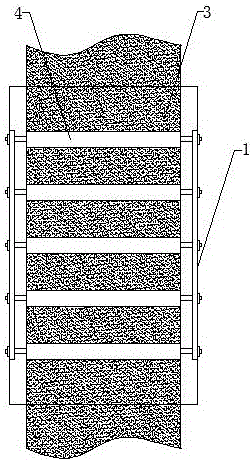

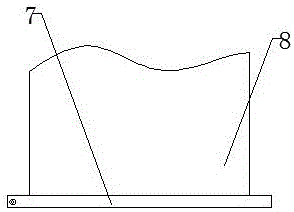

[0019] Refer to attached Figure 1-4 The shown double-roller paper-fed humidifier for motor stator insulating paper includes a humidification chamber 1, which is sealed around the humidification chamber 1, and three humidifiers 2 are arranged at the top and bottom of the humidification chamber 1, each of which A steam hose 21 is arranged at the end of the humidifier 2, and the moisture is emitted outward through the steam hole on the steam hose 21, and the steam hose 21 can be bent to facilitate adjustment of different angles, and the two sides of the humidification chamber 1 Heaters 6 are arranged up and down on the two opposite side walls. The heater 6 is an auxiliary humidifier. The steam sprayed by the humidifier 2 can fully penetrate into the surface and interior of the insulating paper 8 in an environment with high tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com