Cross-shaped section beam type paster double-foot ultrasonic motor vibrator

An ultrasonic motor, cross-shaped technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the difficulties of miniaturization, complex processing and assembly, high processing precision, etc. problems, to achieve the effect of easy miniaturization, convenient processing and assembly, and low processing precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

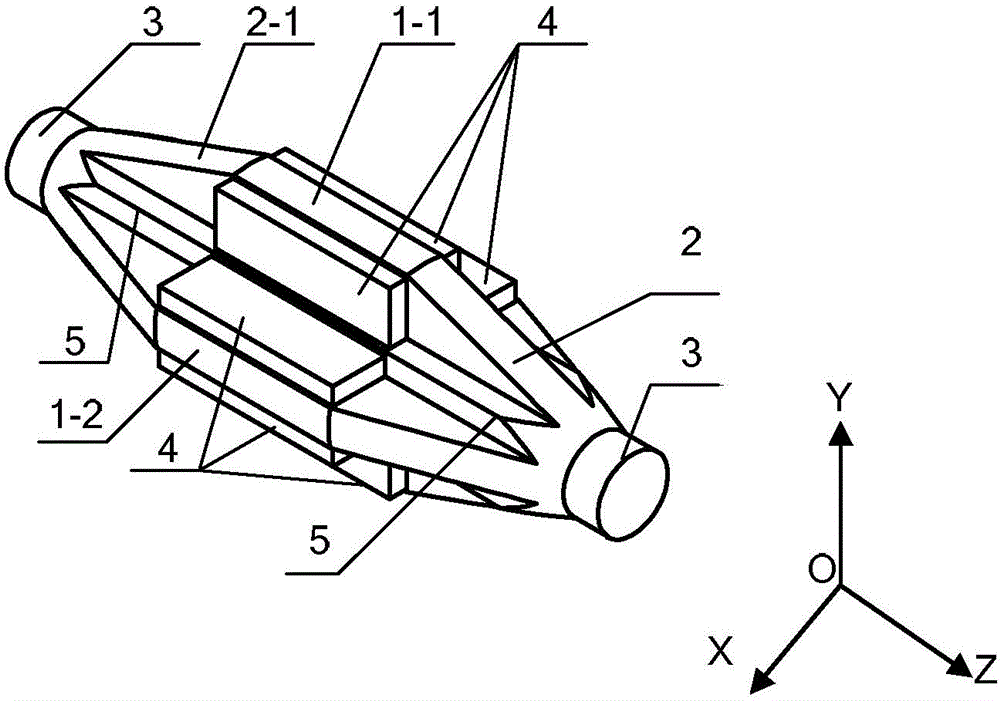

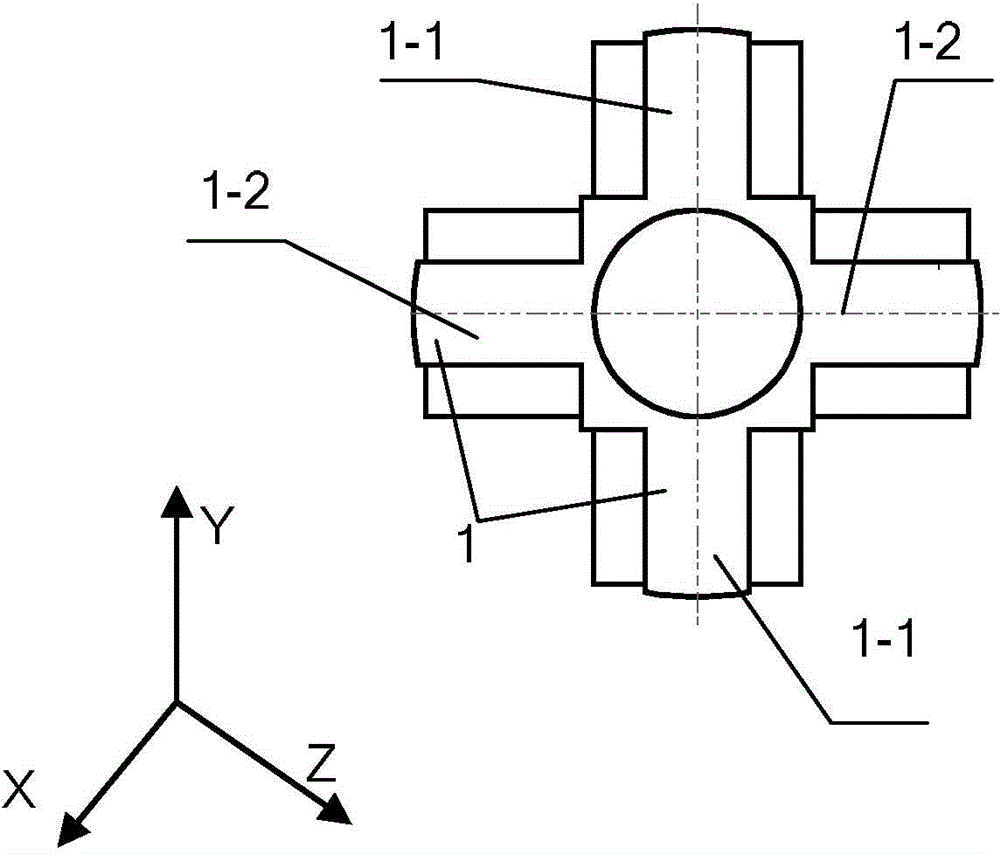

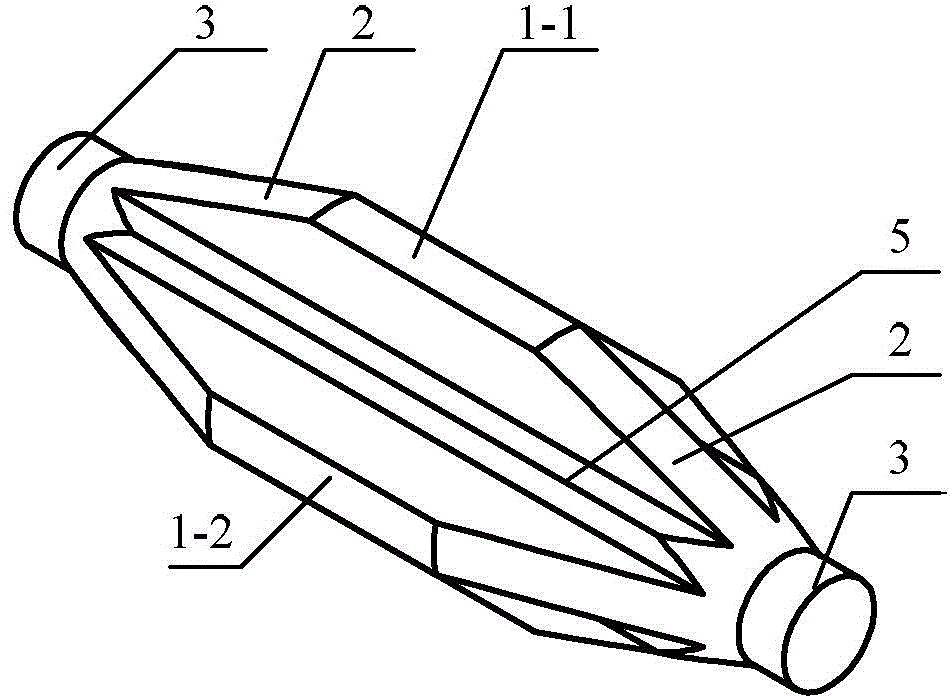

[0023] Specific implementation mode 1, refer to figure 1 , figure 2 with Figure 4 Specifically explain this embodiment, the cross-section beam-type patch biped ultrasonic motor vibrator described in this embodiment includes a middle beam 1, two horns 2, two driving feet 3 and eight piezoelectric ceramic sheets 4;

[0024] The cross-section of the middle beam 1 is cross-shaped, the cross-section of the horn 2 is also cross-shaped, and the cross-section of the horn 2 gradually becomes smaller from the head end to the end, and the two horns 2 are respectively fixed in the middle The two ends of the beam 1; the driving foot 3 is arranged on the top of the small end of the horn 2; the middle beam 1, the two horns 2 and the two driving feet 3 are integrated;

[0025] The eight piezoelectric ceramic sheets 4 are sequentially fixed on eight sides of the middle beam 1; the eight piezoelectric ceramic sheets 4 are all polarized along the thickness direction; the middle beam 1 is co...

specific Embodiment approach 2

[0029] Specific implementation mode two, refer to figure 1 , figure 2 with Figure 5 Specifically explain this embodiment, the cross-section beam-type patch biped ultrasonic motor vibrator described in this embodiment includes a middle beam 1, two horns 2, two driving feet 3 and eight piezoelectric ceramic sheets 4;

[0030] The cross-section of the middle beam 1 is cross-shaped, the cross-section of the horn 2 is also cross-shaped, and the cross-section of the horn 2 gradually becomes smaller from the head end to the end, and the two horns 2 are respectively fixed in the middle The two ends of the beam 1; the driving foot 3 is arranged on the top of the small end of the horn 2; the middle beam 1, the two horns 2 and the two driving feet 3 are integrated;

[0031]The eight piezoelectric ceramic sheets 4 are sequentially fixed on the eight sides of the middle beam 1; the eight piezoelectric ceramic sheets 4 are all polarized along the thickness direction; the four piezoele...

specific Embodiment approach 3

[0033] Specific implementation mode three, refer to figure 1 figure 2 with image 3 Describe this embodiment. This embodiment is a further description of the cross-section beam-type patch biped ultrasonic motor vibrator described in the first or second specific embodiment. In this embodiment, it also includes four bosses 5, so The four bosses 5 are sequentially fixed at the four angles of the middle beam 1, and the thickness of the bosses 5 is greater than the thickness of the piezoelectric ceramic sheet 4. The middle beam 1, the two horns 2, and the two driving Foot 3 and boss 5 are one piece.

[0034] The four bosses can prevent the mutual interference of two adjacent piezoelectric ceramic sheets; the integrated mechanism design can also facilitate the processing and assembly of the vibrator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com