Core-less board manufacturing component, core-less board and manufacturing method for core-less board

A coreless board and component technology, which is applied in multi-layer circuit manufacturing, printed circuit manufacturing, semiconductor/solid-state device manufacturing, etc., can solve problems such as board damage, card board scrapping, warping, etc., to overcome warping and improve yield rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

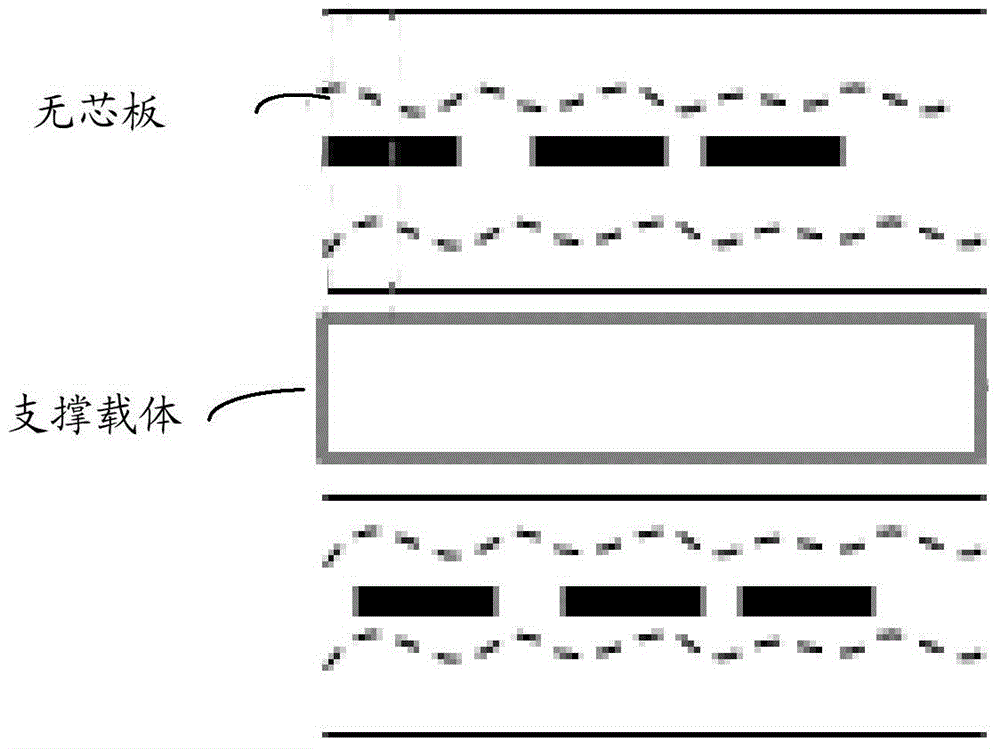

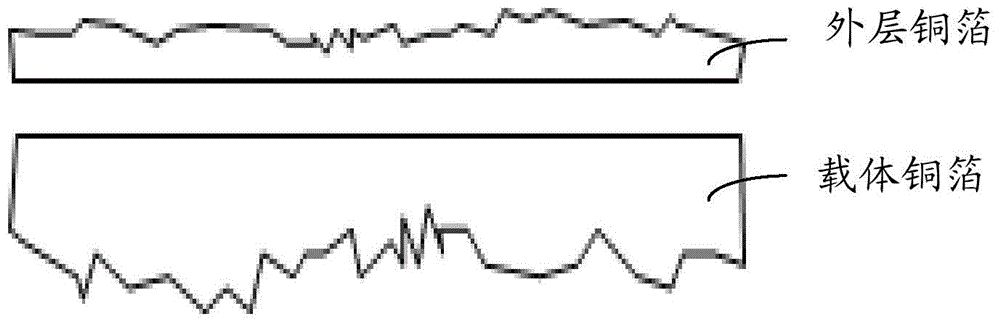

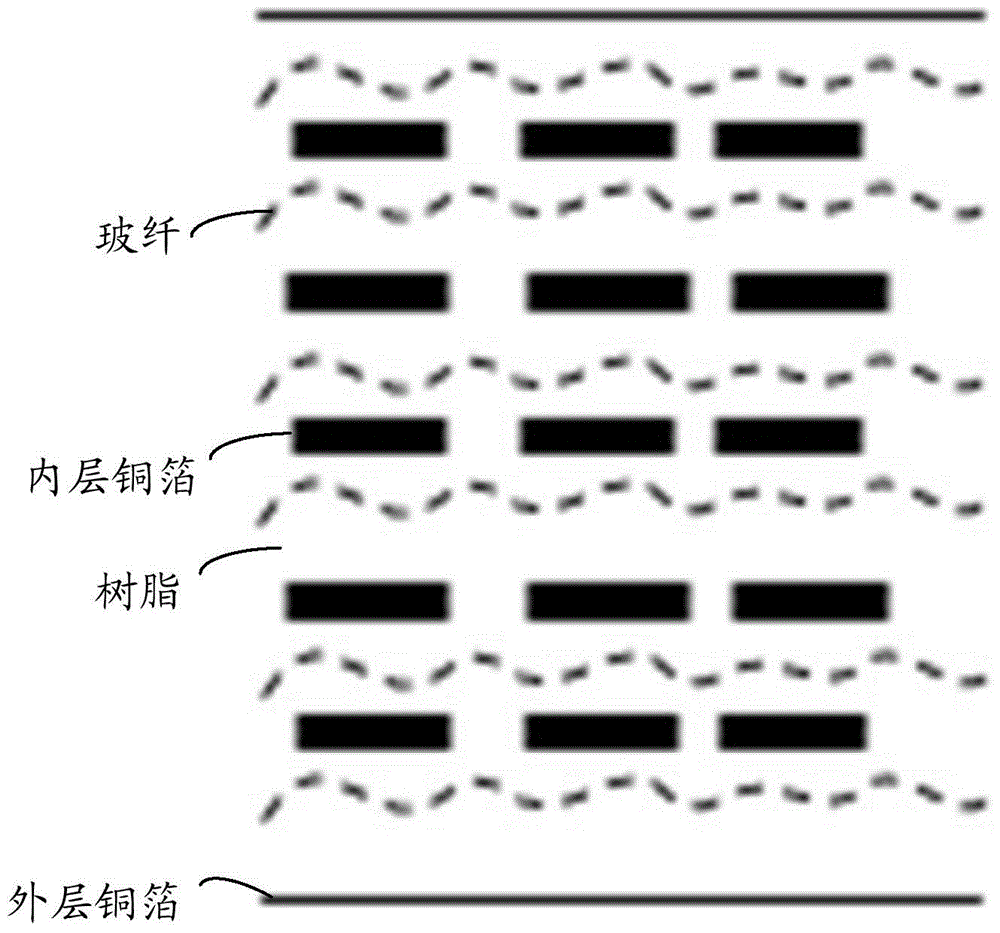

Method used

Image

Examples

Embodiment 1

[0042]

Embodiment 2

[0044]

Embodiment 3

[0046]

[0047] The warpage height refers to the height difference between the two ends of the coreless board; the warpage rate is the value of the height difference divided by the length of the board to represent the degree of warpage of the board.

[0048] The above examples all show that controlling the glass fiber thickness difference between the outer curing sheet and the inner curing sheet to be greater than 8 μm can effectively control the warpage rate below 1%, and the warpage height difference is not higher than 5mm. And the greater the difference in glass fiber thickness, the lower the warpage rate.

[0049] By asymmetrically adjusting and matching the glass fiber thickness and resin content of different layers of prepreg, the warpage reduction of the coreless board can be achieved simply and at low cost.

[0050] In addition, a double-layer glass fiber structure can also be arranged inside the outer curing sheet. The double-layer glass fiber structure includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com