Film processing device and method

A processing device and film technology, which is applied in the field of film drawing device, can solve the problems of low longitudinal thermal shrinkage rate, heavy load of steel belt, elongation and deformation of steel belt in horizontal pull track, etc., so as to improve longitudinal thermal shrinkage rate and save installation Space, the effect of ensuring the clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

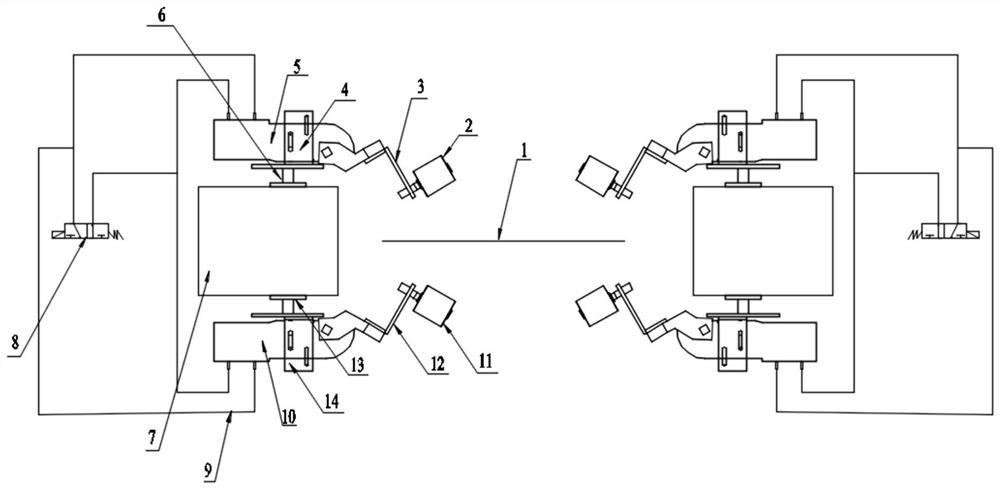

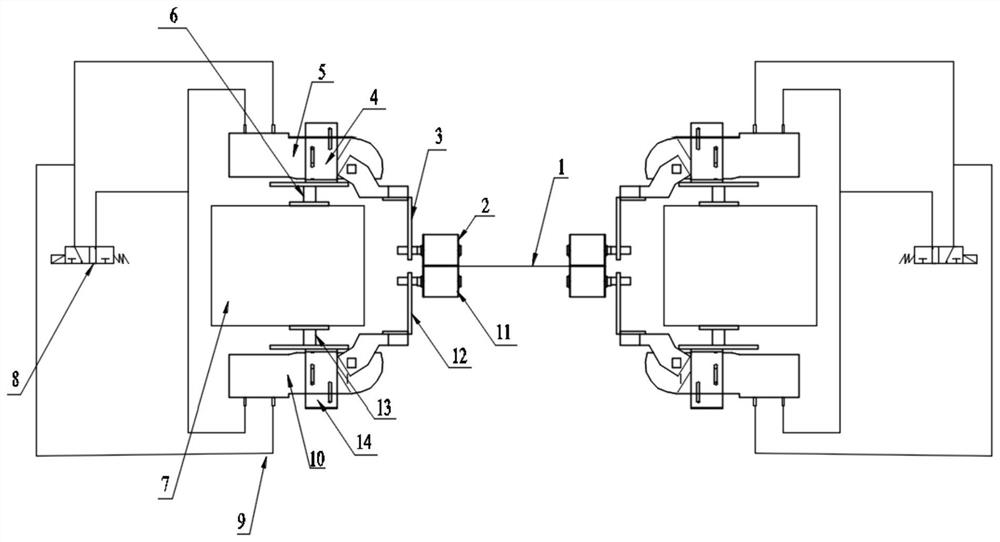

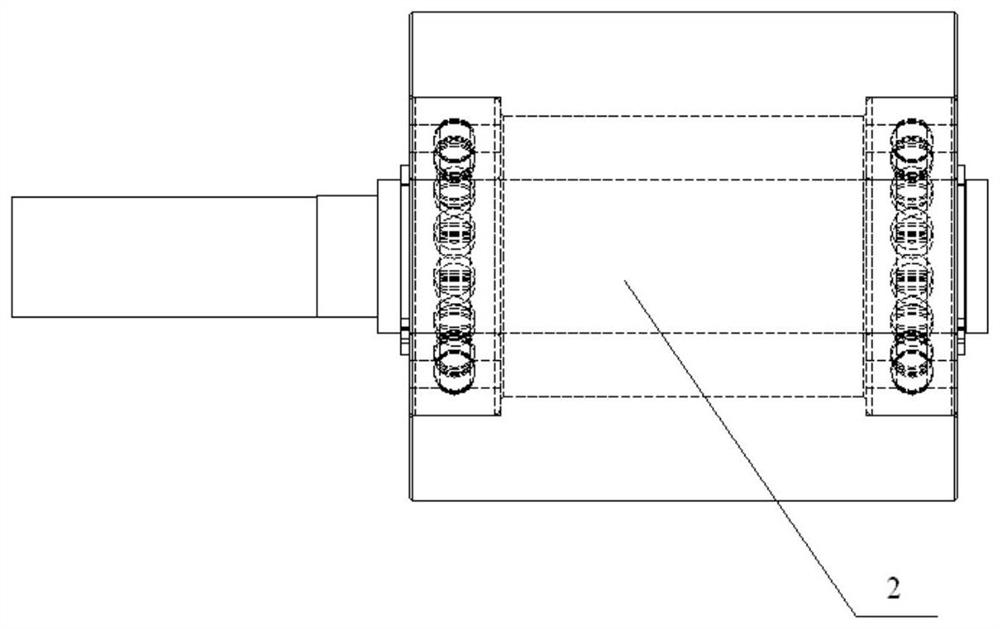

[0041] Depend on figure 2 Given, the film processing device of the present invention comprises a horizontal stretch box and a horizontal stretch unit, the horizontal stretch unit is located in the horizontal stretch box, and the horizontal pull unit includes two chain clip tracks 7 and is installed on the chain clip track 7 The horizontal pull chain 19 of parallel endless rotation on the top; the horizontal pull unit includes: the horizontal pull nip roller unit and the horizontal pull cutter unit arranged in the horizontal pull box; the horizontal pull box includes the N3 area in the horizontal pull box, Cooling Zone 1 and Cooling Zone 2, the N3 Zone, Cooling Zone 1, and Cooling Zone 2 are arranged in sequence along the pulling direction of the film 1; the horizontal stretching nip roller unit includes two sets of nip rollers; the two sets of nip rollers Separately located in the cooling zone 1 and the cooling zone 2; each set of nip rolls can clamp both sides of the film 1 ...

Embodiment 2

[0047] Depend on figure 1 , figure 2 Given, different from Embodiment 1, in order to ensure the safety of personnel and equipment on the production line, the production safety line is provided with a membrane rupture signal, which is connected in parallel with the solenoid valve 8, and the solenoid valve acts immediately in the event of an accidental membrane rupture. In order to realize the timely opening of the nip rollers, the film processing devices all enter the non-working position state, so as to prevent the film from causing harm to personnel and equipment on the line.

Embodiment 3

[0049] Depend on figure 1 , figure 2 and Figure 6 Given, different from Embodiment 1 and Embodiment 2, the upper cylinder fixing bracket 4 and the lower cylinder fixing bracket 14 are respectively provided with two sets of parallel screw holes 41 and 42 with different heights, and the screw holes 41 and 42 are all designed as a straight waist groove structure, the center line of the straight waist groove is perpendicular to the film 1, and the upper and lower ends of the straight waist groove are sealed with a semicircular arc tangent to the edge of the groove. The width of the straight waist groove is the same as the diameter of the semicircle, the distance between the centers of the upper and lower half arcs of each waist groove is 50mm, and the width of the waist groove is 11mm. Adjust the installation height of the cylinder according to the clamping force of the nip roller to achieve the desired clamping force and ensure that the clamping force of the film does not loo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com