Horizontal rolling process and forming device for special-shaped ring piece

A forming device and special-shaped ring technology, which is applied in metal rolling and other directions, can solve the problems of affecting the quality of formed products, lowering the yield rate, and wasting processes, so as to save the time for adjusting the bracket, overcome the problem of ring warping, The effect of reducing the number of replacements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] In order to make the objects, technical solutions and advantages of the present invention, the present invention will be described in further detail below with reference to the accompanying drawings and examples. It is to be understood that the specific embodiments described herein are intended to explain the present invention and is not intended to limit the invention.

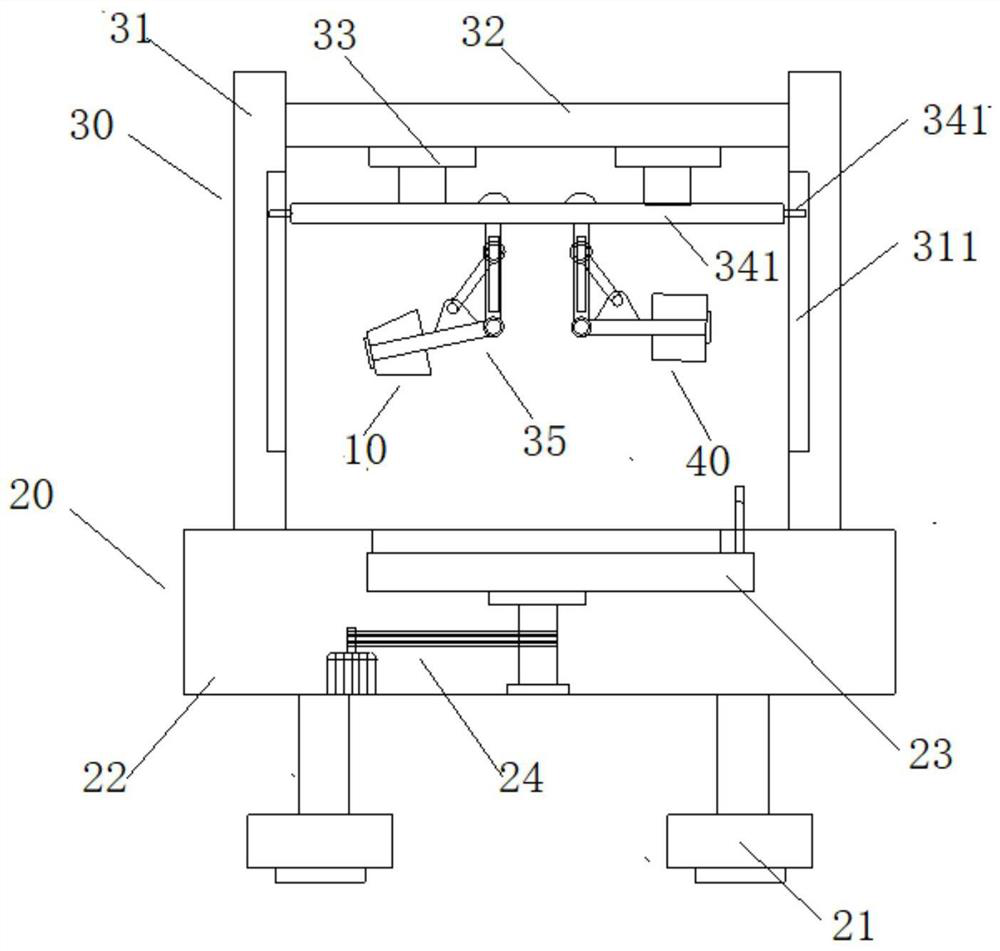

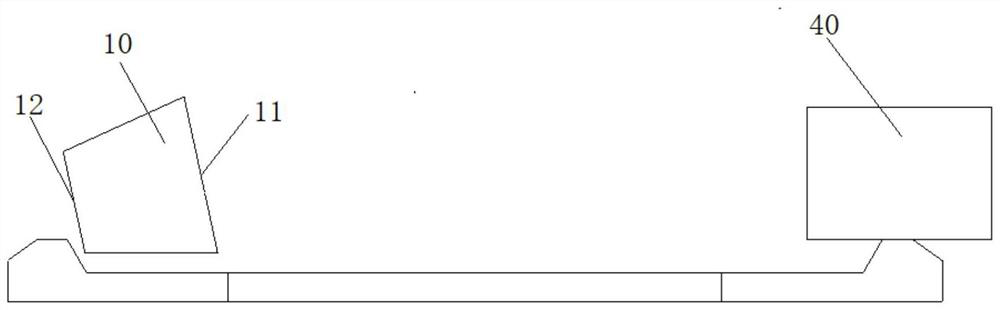

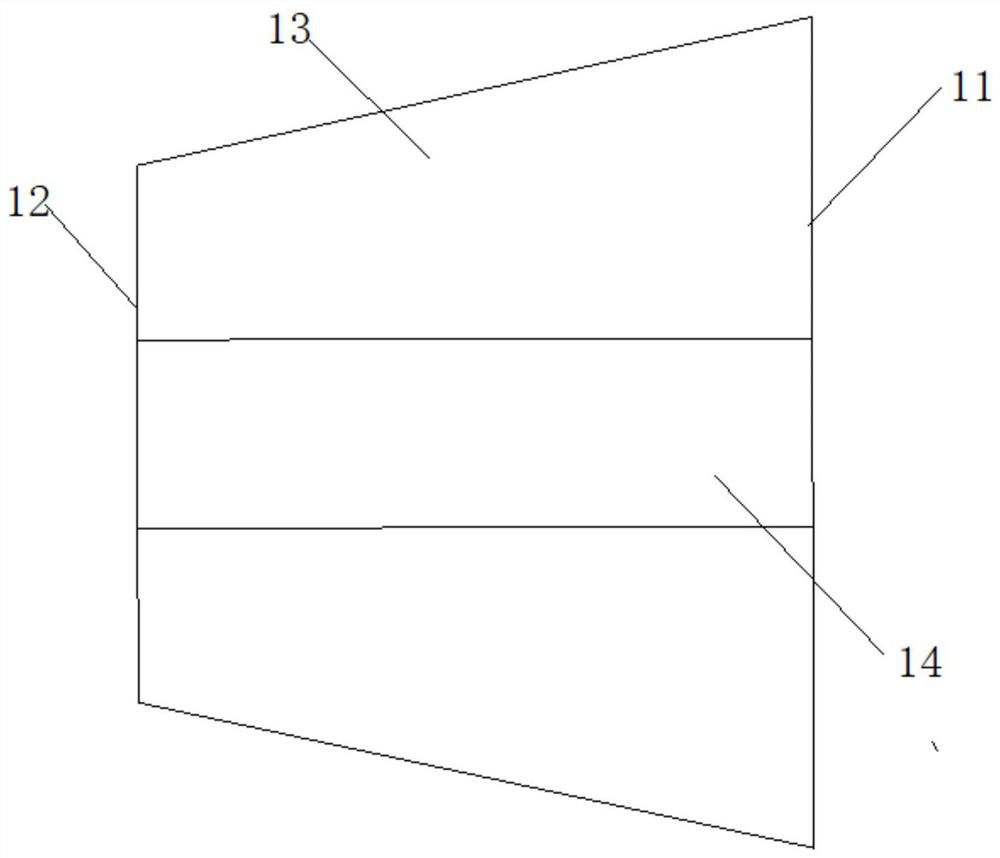

[0067] Referring to the following drawings, the structure of the roller 10, the work platform 20, the bracket 30, the press wheel 40 of the present invention, and the connection relationship thereof are further illustrated:

[0068] The horizontal rolling process of the shaped ring, including the following steps:

[0069] Step 1: The blank is heated to 1100 ° C forging temperature, and press the billet to form a cake shape using a press, and the intermediate portion is stamped;

[0070] Step 2: Move the ring blank obtained by step to the work platform;

[0071] Step 3: Using two opposing rolling wheels and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com