Two-pack type curable coating agent

A curing type, coating agent technology, used in coatings, polyurea/polyurethane coatings, etc., can solve the problems of poor scratch resistance and chemical resistance of the coating layer, low productivity, and cracking of the coating layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

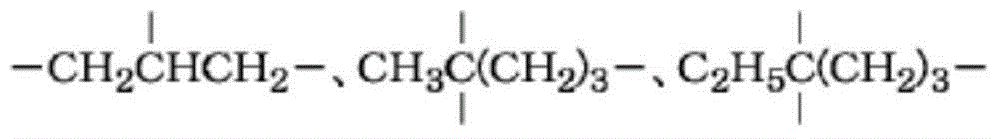

Method used

Image

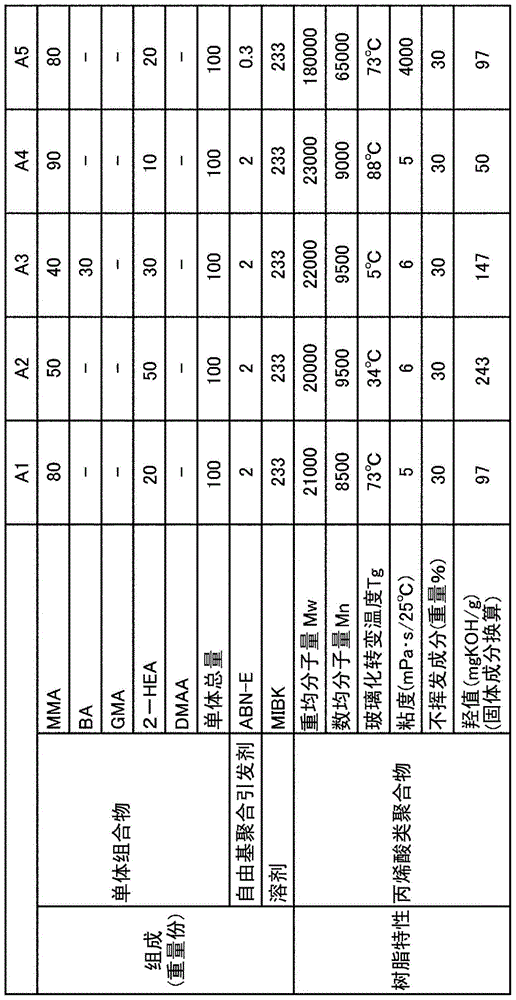

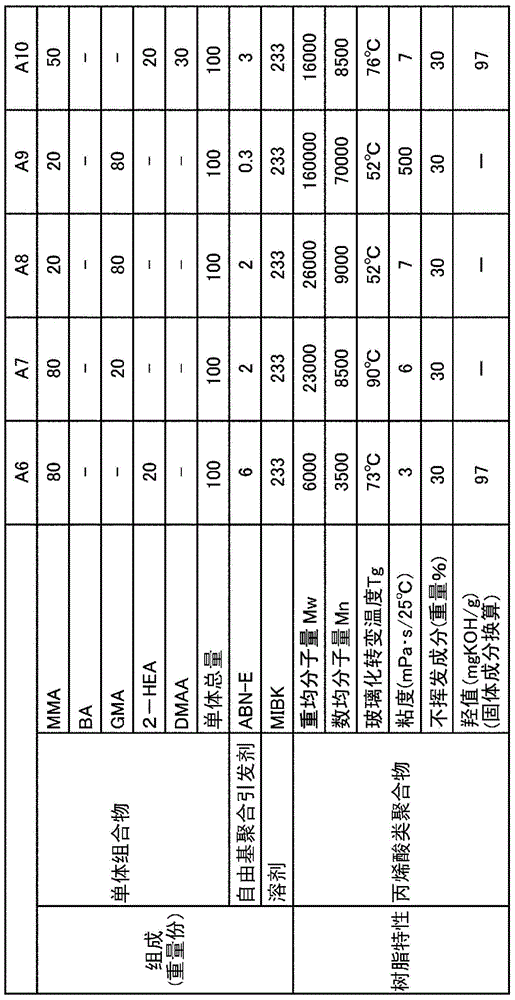

Examples

Embodiment 1~30、 comparative example 1~17

[0181] γ-isocyanatopropyltriethoxysilane (trade name "KBE-9007" manufactured by Shin-Etsu Chemical Co., Ltd.), N-2-(aminoethyl)- 3-Aminopropyltriethoxysilane (trade name "KBE-603" manufactured by Shin-Etsu Chemical Co., Ltd.), glycidoxytrimethoxysilane (trade name "KBM-403" manufactured by Shin-Etsu Chemical Co., Ltd. "), polyoxyethylene polyoxypropylene glycol ether (trade name "EPAN U105" of Daiichi Kogyo Pharmaceutical Co., Ltd., hydroxyl value: 19mgKOH / g, average number of functional groups: 2, weight average molecular weight: 6400), polyoxypropylene glycol ether ( Sanyo Chemical Industry Co., Ltd. product name "SANNIX PP-1000", hydroxyl value: 112 mgKOH / g, average number of functional groups: 2, weight average molecular weight: 1000), polycaprolactone triol (Daicel Chemical Industries, Ltd. trade name "PLACCEL 303" of Daicel Chemical Industries, Ltd.), polycaprolactone diol (trade name "PLACCEL 205" of Daicel Chemical Industries, Ltd.), pentaerythritol triacrylate hexamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com