Multipoint reciprocating continuous crystallizer

A crystallizer and reciprocating technology, applied in the direction of crystallization separation, chemical instruments and methods, separation methods, etc., can solve the problem that the effect of countercurrent washing cannot be greatly improved, achieve high purification effect, increase the effect of countercurrent washing, and speed up renewal Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

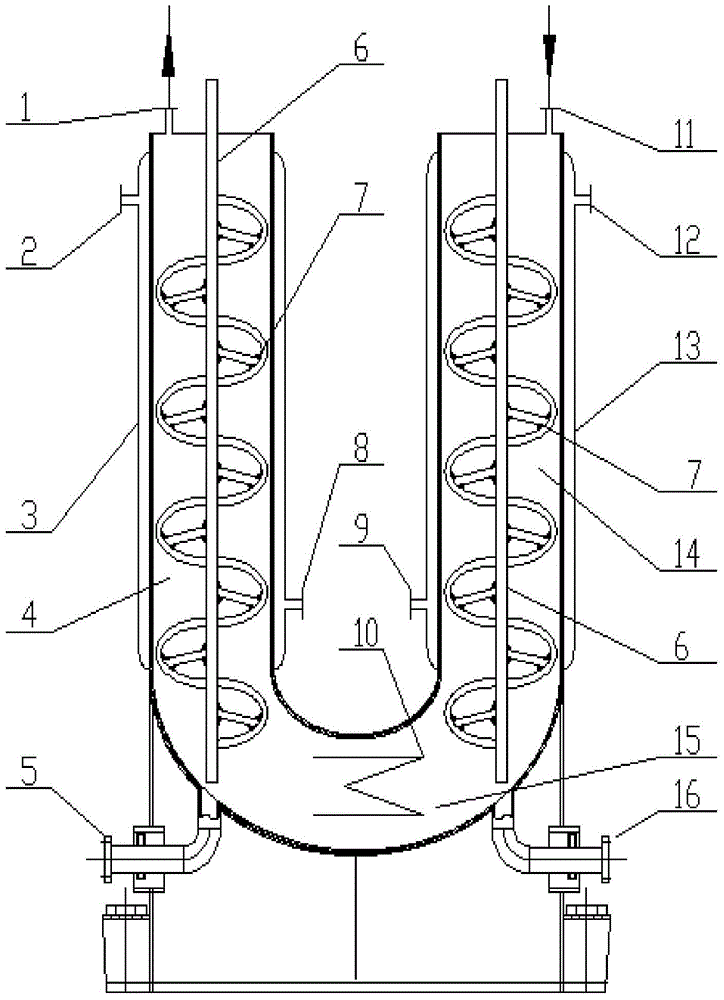

[0020] Adopt multi-point reciprocating continuous crystallizer of the present invention (as figure 1 As shown), the material enters the crystallizer purification section 14 from the feed port 11, and flows to the raffinate outlet 1. A heating jacket 3 is arranged outside the purification section 14, and the heating agent of the jacket is added in a bottom-in and top-out manner, so that the temperature of the purification section 14 rises gradually from top to bottom. After the material is added, crystals are precipitated after mixing the liquid phase in the original tower, and the temperature and flow rate entering the jacket heating agent inlet 9 are controlled to control the temperature distribution of the purification section 14, and a certain crystal bed is formed in the purification section 14. Using the stirring shaft 6 and The spiral stirrer 7 transports the crystals to the melting section 15 . In this process, controlling the temperature distribution of the purificati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com