A melting crystallization tower and crystallization method

A crystallization tower and crystallization technology, applied in the field of crystallization towers, can solve problems such as the influence of the separation effect of the crystallization tower, and achieve the effects of efficient treatment, accelerated interface renewal, and increased countercurrent washing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

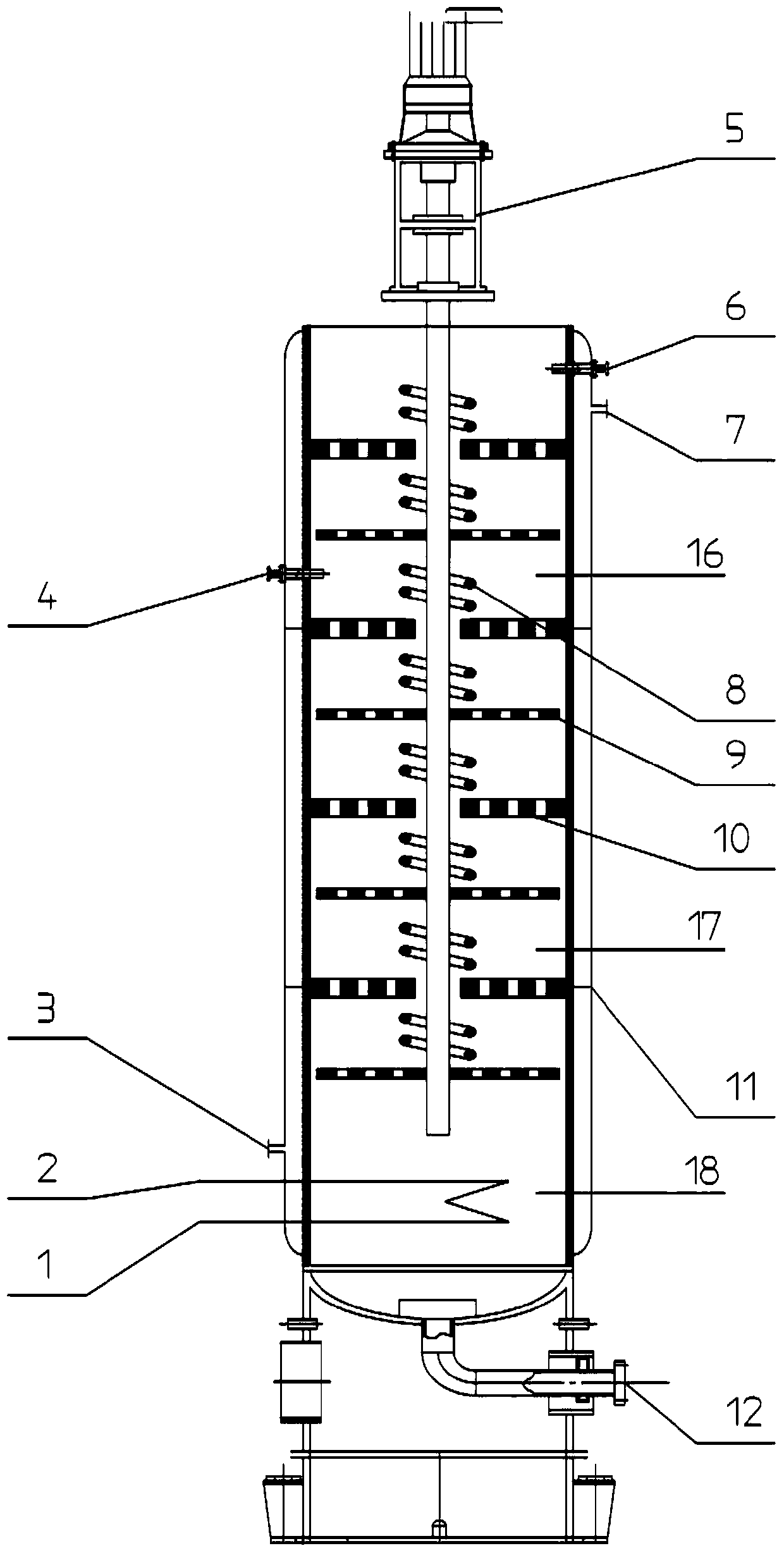

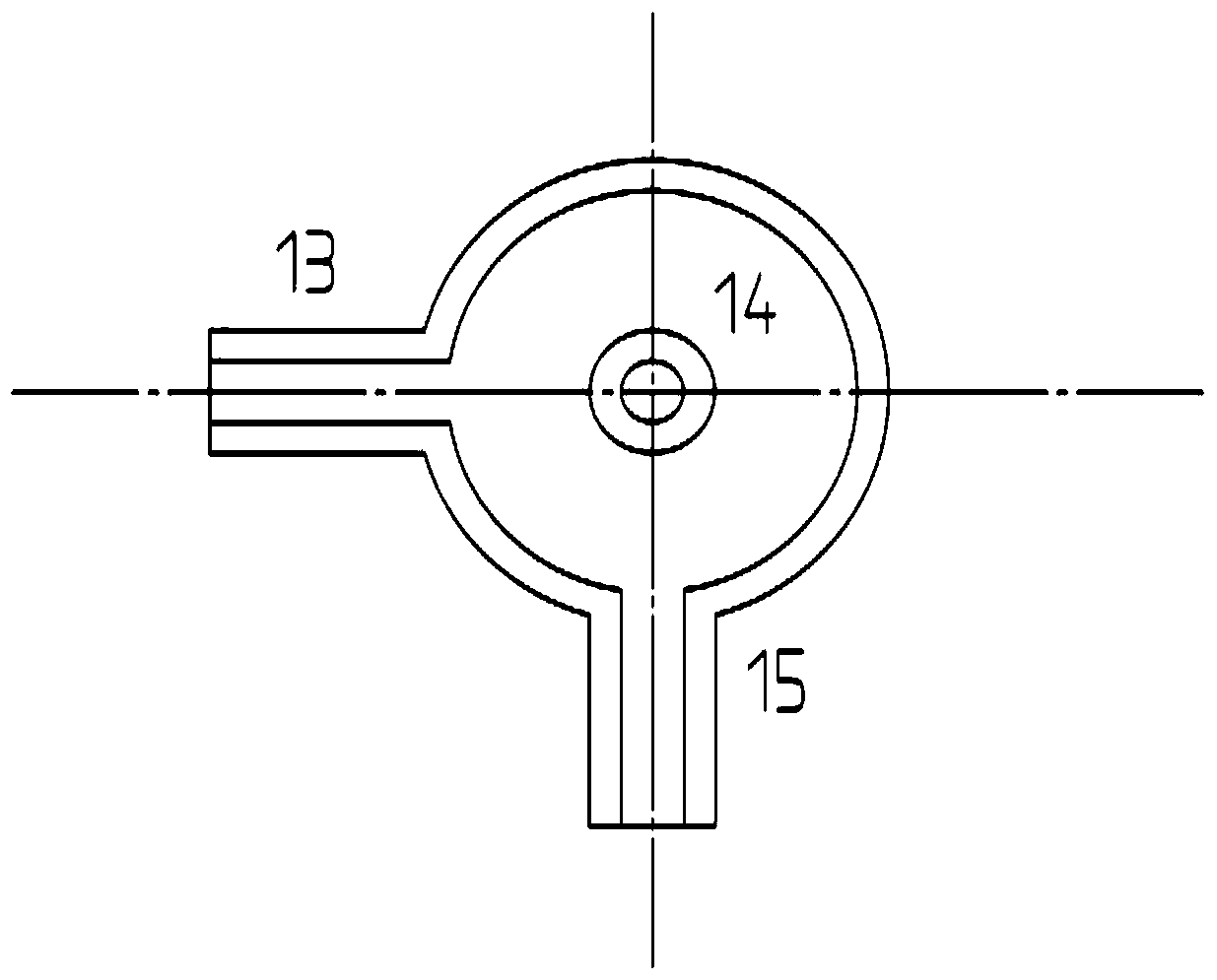

[0016] combine figure 1 and figure 2 Preferred embodiments of the present invention are described.

[0017] The height of the crystallization tower that present embodiment adopts is 1350mm, and inner diameter is 50mm. There are 4 sieve plates in the tower, and the distance between the sieve plates is 250mm. Among them, there are four small propellers and a large propeller in the middle between every two layers of sieve plates. The blades of the large propeller are 60° fan-shaped and have 3 blades.

[0018] The isolated substances are p-o, p-nitrochlorobenzene. The feed concentration is 90.85%, the set reflux ratio is 2.5, and the stirring rate is 10 rpm. The purity of the outlet material is increased from 90.85% to 99.99% at a crystal bed height of less than 1m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com