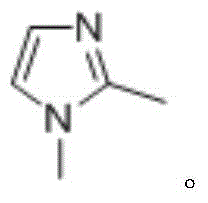

Method for synthesizing 1,2-dimethylimidazole and used supported catalyst

A supported catalyst, dimethylimidazole technology, applied in the field of preparation of supported catalysts, can solve the problems of high energy consumption, high temperature, etc., achieve good selectivity, high selectivity, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

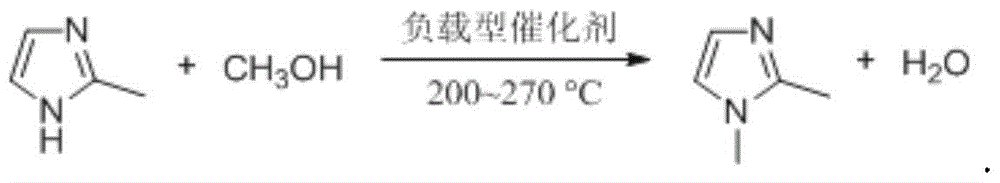

Method used

Image

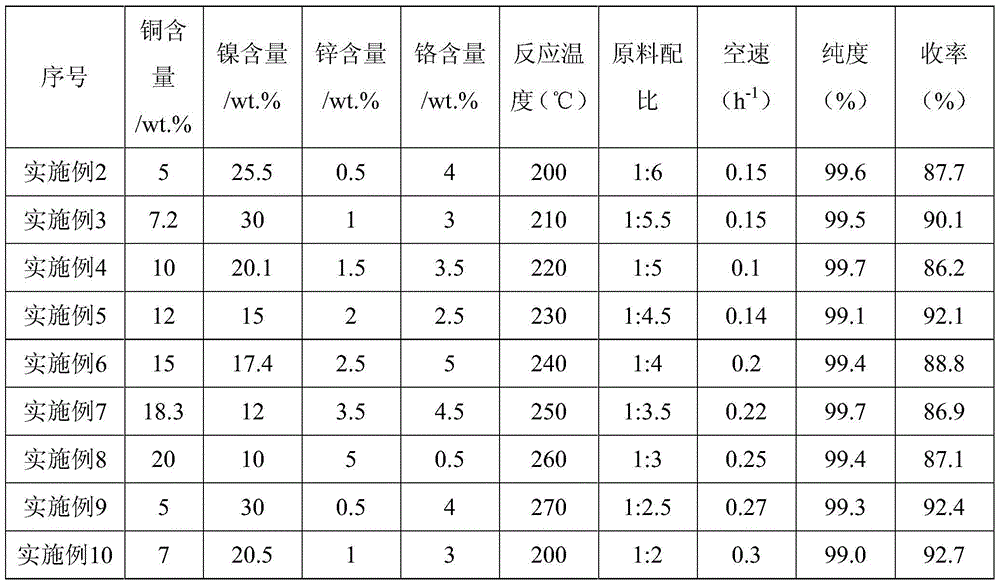

Examples

Embodiment 1

[0044] One, be used for the preparation method of the loaded catalyst of 2-methylimidazole and methanol reaction synthetic 1,2-dimethylimidazole, carry out following steps successively:

[0045] 1), initial roasting: commercially available γ-Al 2 o 3 (Particle diameter is 2-3mm) calcined at 400-500°C for 2h, and then calcined at 600-650°C for 7h to obtain the calcined γ-Al 2 o 3 ; After detection: the γ-Al 2 o 3 The specific surface area is 210 ~ 230m 2 / g, the pore size is 15.7~16.5nm, and the particle diameter is basically unchanged;

[0046] 2), the roasted γ-Al obtained in step 1) 2 o 3 Immerse in a closed container containing distilled water for 72 hours, then measure the volume of water reduction, and calculate the γ-Al after roasting 2 o 3 The pore volume is 1.0mL / g;

[0047] 3), initial impregnation: 47.9g copper nitrate trihydrate, 115.2g nickel nitrate hexahydrate, 21.3g zinc nitrate hexahydrate and 20.8g chromium nitrate nonahydrate were dissolved in disti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com