Uniform-sprinkling-irrigation 2000-stage adjustable spray nozzle of center pivot sprinkling machine and adjustment method

A technology of sprinkler and sprinkler, which is applied in the direction of sprinkler and sprinkler, can solve problems such as change and practical application inconvenience, achieve uniform sprinkler irrigation, meet market demand, and save costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

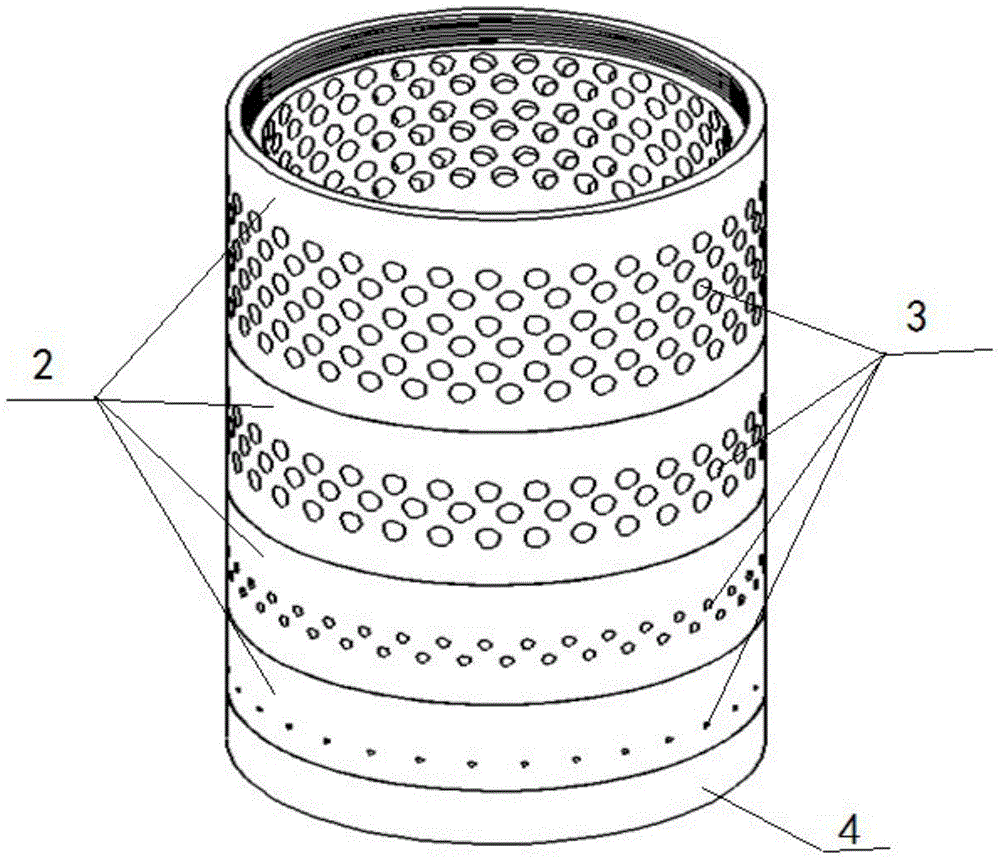

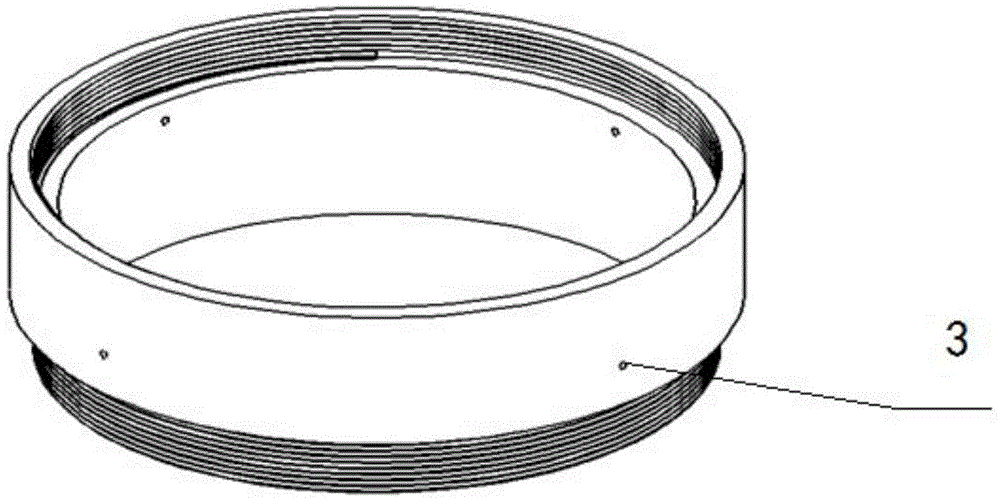

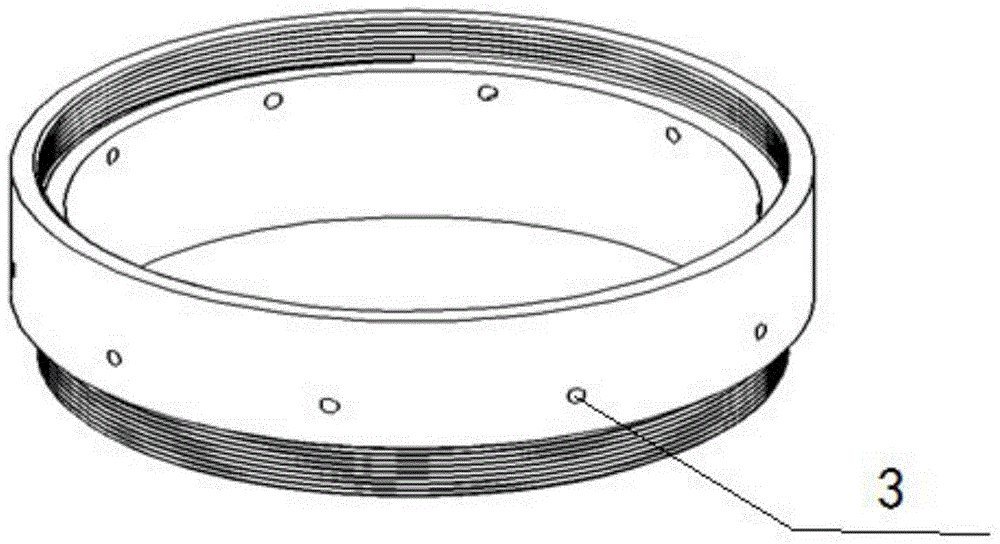

[0052] Universal nozzle 2 in the present embodiment (referring to Figure 2-4 ) is cylindrical, with threads at both ends of the nozzle, and the threads at both ends can cooperate with each other. The diameter of the nozzle is 45mm, the radius of the reference nozzle hole is 0.5mm, and the nozzle holes are evenly distributed in the middle of the nozzle. According to the number and requirements of the above nozzle holes The 12 types of nozzle serial numbers obtained from production have the same nozzle shape and specifications, but the number of nozzle holes or the radius of the nozzle holes are different.

[0053] Truss in this embodiment (see Figure 5 ) is 50m in length, and the truss lower end cantilever 7 is arranged at equal intervals on the truss. One end of 6 is on the left, and the serial numbers of the nozzles are marked from left to right along the length of the truss 5. The selection of the nozzle configuration is actually to determine the equivalent opening size o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com